Color-variable art paint and preparation method thereof

An art paint, photochromic technology, applied in the field of color-changing art paint and its preparation, can solve the problems of harming direct contacts, single wall color, cobalt salt toxicity, etc., achieving good color transformation effect, beautifying the environment, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

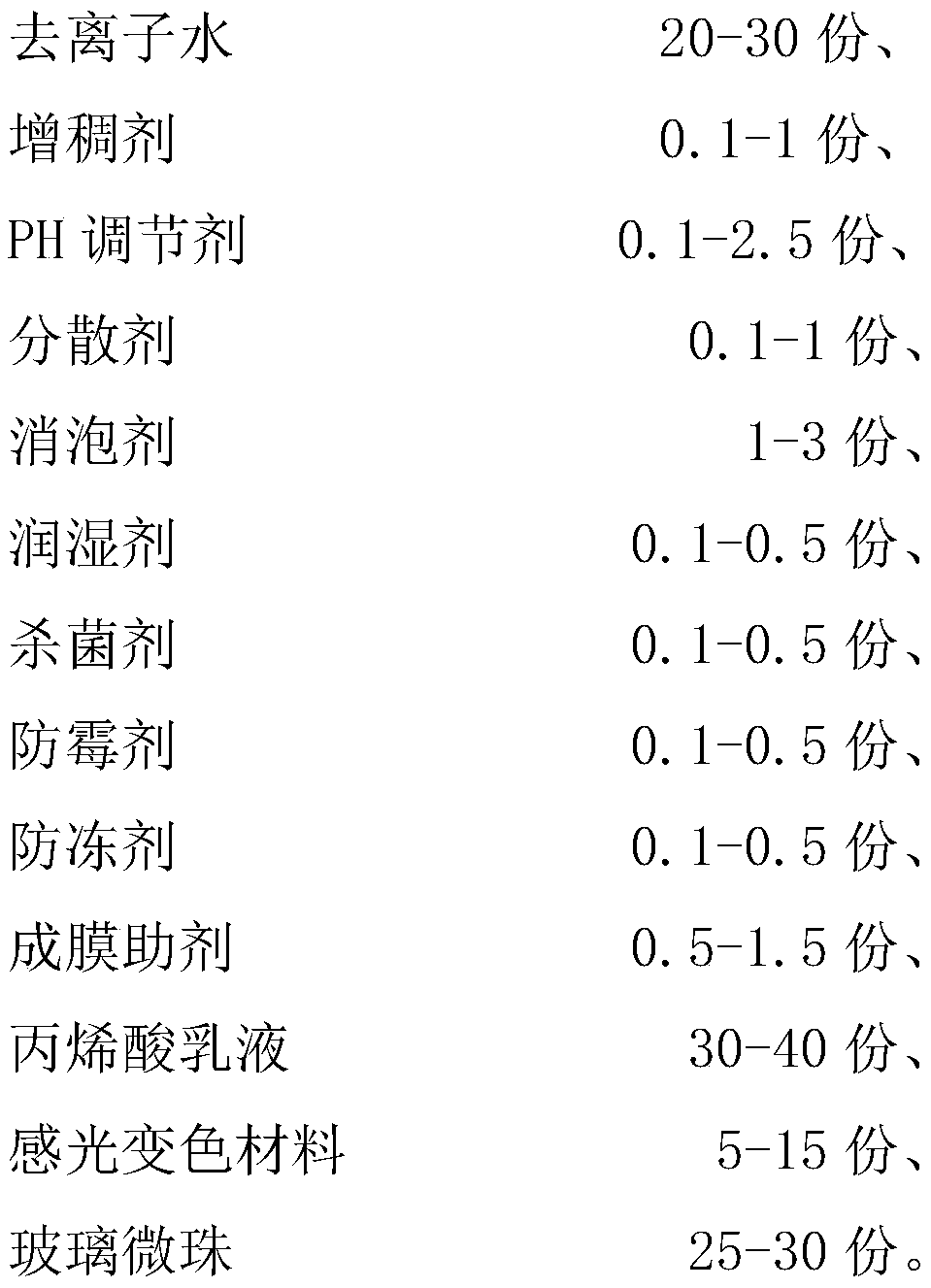

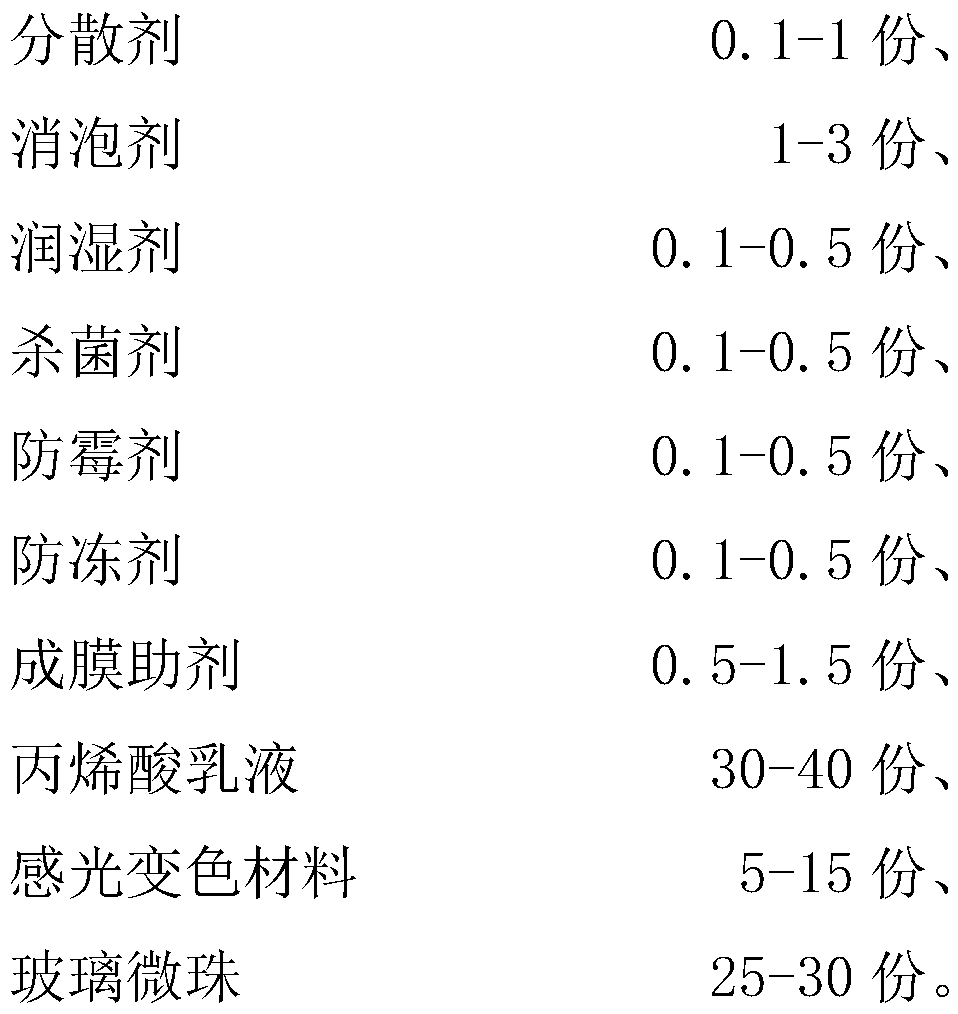

[0036] A kind of color-changing art paint, in parts by mass, comprises the following components:

[0037] 27 parts of deionized water, 0.7 parts of thickener, 0.3 parts of PH regulator, 0.4 parts of dispersant, 2 parts of defoamer, 0.2 part of wetting agent, 0.2 part of fungicide, 0.2 part of mold inhibitor, 0.3 part of antifreeze , 0.7 parts of film-forming aids, 35 parts of acrylic emulsions, 7 parts of photochromic materials, and 25 parts of glass beads; wherein, photochromic materials include silver bromide and copper oxide with a mass ratio of 3:2:2:3:4 , Nano molybdenum disulfide sheet, azo polyurethane, hexamethylene tetramine.

[0038] The preparation method of above-mentioned discoloration art paint, comprises the following steps:

[0039] (1) Mixing, dissolving, stirring, swelling, and dispersing deionized water, a thickener, and a pH regulator to obtain a mixed solution;

[0040] (2) In the mixed solution obtained in step (1), slowly add dispersant, wetting agent,...

Embodiment 2

[0046] A kind of color-changing art coating, by mass parts, comprises following component:

[0047] 23 parts of deionized water, 0.7 parts of thickener, 0.3 parts of PH regulator, 0.4 parts of dispersant, 1.5 parts of defoamer, 0.2 parts of wetting agent, 0.2 parts of bactericide, 0.2 parts of antifungal agent, 0.3 parts of antifreeze , 0.85 parts of film-forming aids, 40 parts of acrylic emulsions, 10 parts of photochromic materials, and 27 parts of glass beads; wherein, photochromic materials include silver bromide and copper oxide with a mass ratio of 3:2:2:2:4 , Nano molybdenum disulfide sheet, azo polyurethane, hexamethylene tetramine.

[0048] The preparation method of above-mentioned discoloration art paint, comprises the following steps:

[0049] (1) Mixing, dissolving, stirring, swelling, and dispersing deionized water, a thickener, and a pH regulator to obtain a mixed solution;

[0050] (2) In the mixed solution obtained in step (1), slowly add dispersant, wetting ...

Embodiment 3

[0056] A kind of color-changing art coating, by mass parts, comprises following component:

[0057] 20 parts of deionized water, 0.7 parts of thickener, 0.3 parts of PH regulator, 0.4 parts of dispersant, 3 parts of defoamer, 0.2 part of wetting agent, 0.2 part of fungicide, 0.2 part of antifungal agent, 0.5 part of antifreeze , 1.5 parts of film-forming aids, 40 parts of acrylic emulsion, 13 parts of photochromic materials, and 30 parts of glass beads; wherein, photochromic materials include silver chloride and copper oxide with a mass ratio of 3:2:2:4:3 , Nano molybdenum disulfide sheet, azo polyurethane, hexamethylene tetramine.

[0058] The preparation method of above-mentioned discoloration art paint, comprises the following steps:

[0059] (1) Mixing, dissolving, stirring, swelling, and dispersing deionized water, a thickener, and a pH regulator to obtain a mixed solution;

[0060] (2) In the mixed solution obtained in step (1), slowly add dispersant, wetting agent, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com