Preparation method of carbon quantum dots

A technology of carbon quantum dots and hydrothermal method, applied in the field of carbon quantum dots processing, can solve problems such as inability to meet, and achieve the effect of eliminating environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: In this embodiment, a method for preparing carbon quantum dots is based on corn stalks and methyl methacrylate distillation reaction bottom waste as raw materials, specifically through the following steps:

[0026] Step 1. After crushing the corn stalks, pass through a 60-mesh sieve, weigh 1g of corn stalks and 50g of methyl methacrylate distillation reaction bottom waste, mix them, and put them into a common oven for hydrothermal reaction. The reaction temperature is 100°C. The reaction time is 2;

[0027] Step 2, then add oxalic acid and the pH value is 3;

[0028] Step 3: react at 130°C for 2 hours, and then freeze-dry at minus 50°C for 24 hours to obtain carbon quantum dots.

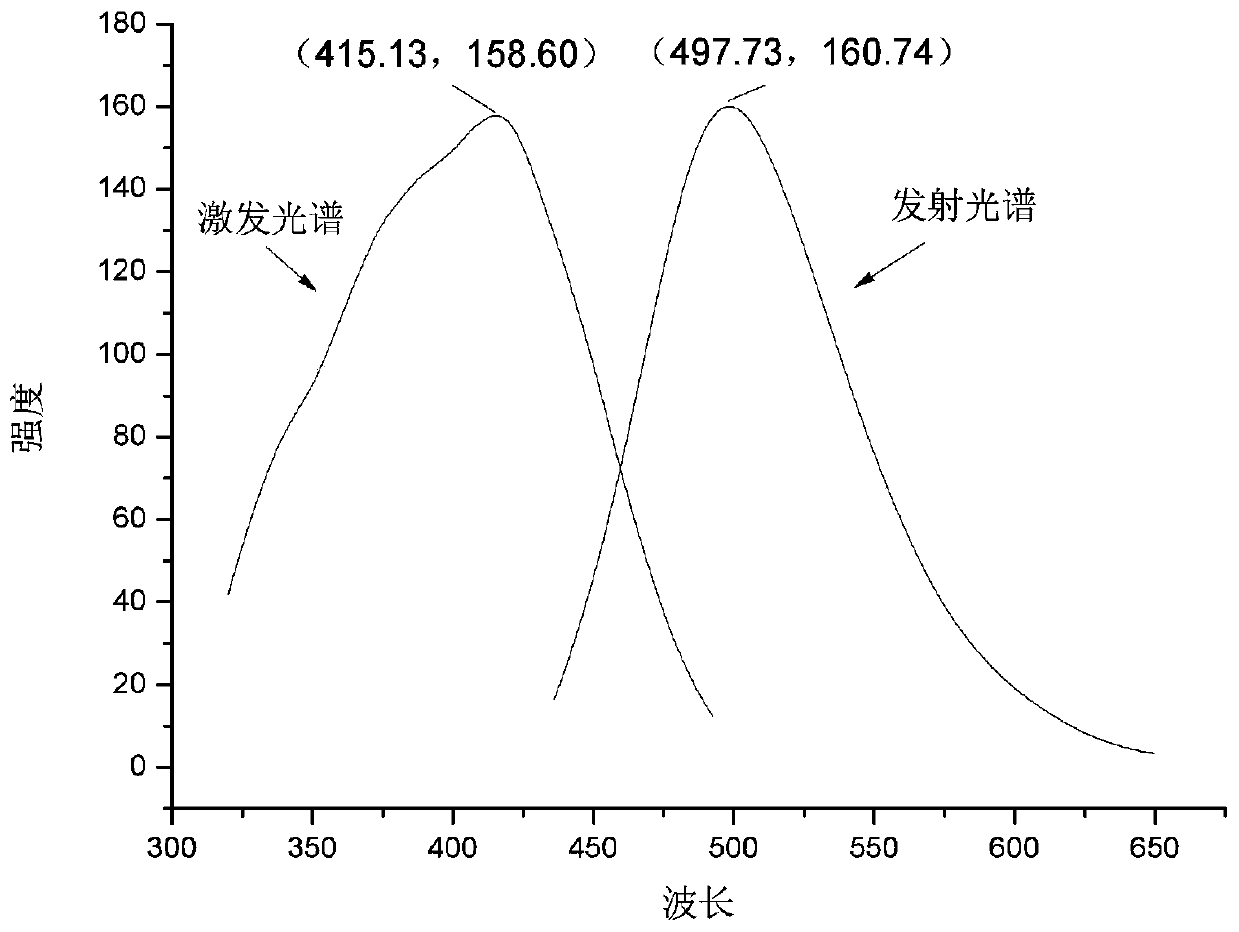

[0029] The fluorescence spectrum of carbon quantum dots in this embodiment is as follows figure 1 shown by figure 1 It can be seen that the prepared carbon quantum dots emit green fluorescence. Location map of excitation and emission wavelengths figure 1 shown.

Embodiment 2

[0030] Example 2: A method for preparing carbon quantum dots in this example is based on peanut straw and methyl methacrylate distillation reaction bottom waste as raw materials, specifically through the following steps:

[0031] Step 1. After crushing the peanut straw, pass it through a 60-mesh sieve, weigh 1g of peanut straw and 50g of the waste from the bottom of the methyl methacrylate distillation reaction kettle, mix them, and put them into microwave hydrothermal reaction. The reaction temperature is 100°C, and the reaction time is for 30 minutes;

[0032] Step 2, then add 1g of oxidant, then add 1g of hydrogen peroxide, and adjust the pH value to 8 with ammonia water;

[0033] Step 3: React at 150°C for 1 hour, and then freeze-dry at minus 50°C for 24 hours to obtain carbon quantum dots.

Embodiment 3

[0034] Embodiment 3: The preparation method of a kind of carbon quantum dot in this embodiment is to use the mixture of soybean seed coat and mushroom, and the bottom waste of methyl methacrylate distillation reaction tank as raw materials, specifically through the following steps:

[0035] Step 1. After crushing soybean seed coats, pass through a 60-mesh sieve, weigh 0.5g soybean seed coats, 0.5g mushrooms and 60g methyl methacrylate distillation reaction bottom waste, mix them, put them into microwave hydrothermal reaction, and react The temperature is 90°C, and the reaction time is 30 minutes;

[0036] Step 2, then add 2g of hydrogen peroxide, and then add urea to adjust the pH value to 8;

[0037] Step 3, react at 180°C for 0.5h, and then freeze-dry at minus 50°C for 24 hours to obtain carbon quantum dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com