MoO<3-x>/g-C<3>N<4> composite photocatalytic material, and preparation method and application thereof

A composite photocatalysis, g-c3n4 technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Separation of VOCs, reducing the energy utilization of surface water molecules, etc., to achieve the effects of increasing vaporization speed, high photothermal conversion efficiency, and high quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

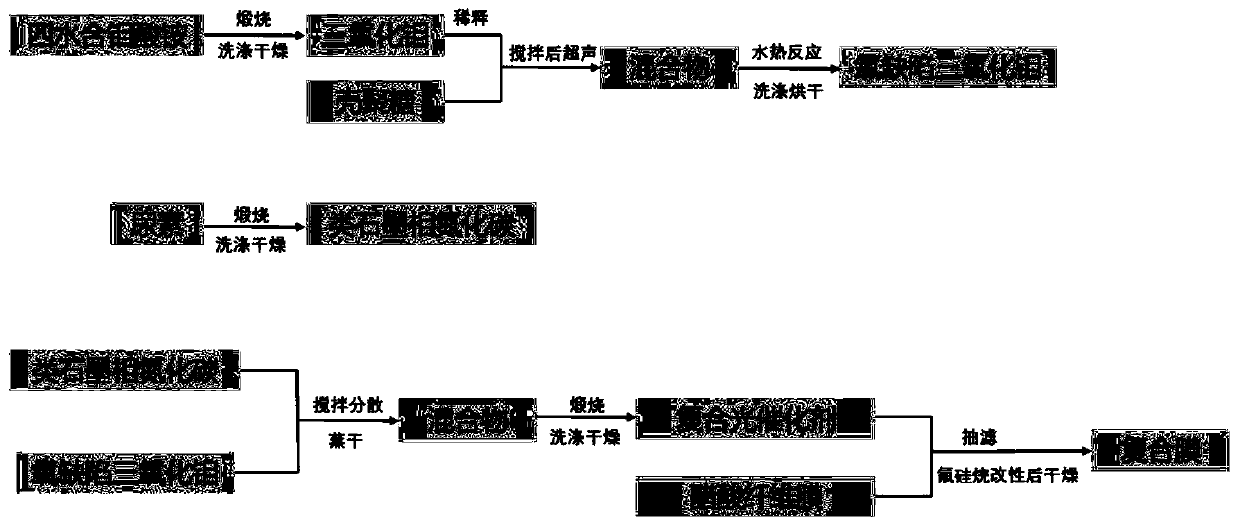

[0033] Preparation of loaded MoO 3-x Composite film:

[0034] Calcinate 10g of ammonium molybdate tetrahydrate at 500°C for 4h, wash and dry to obtain molybdenum trioxide MoO 3 , the 1g MoO 3 Disperse in 30mL of deionized water, add 4g of chitosan to the deionized water, stir for 30min and then ultrasonic for 30min, mix well, transfer the mixture to the reactor and react at 180°C for 8h; after the reaction, filter the reaction solution , to obtain a solid product, the solid product was washed and dried to obtain MoO 3-x ; Hydrophobic modification of cellulose acetate membrane (CA) was carried out with 300 μL fluorosilane, and dried at 80 ° C after modification; 20 mg MoO 3-x Dispersed in water, the MoO was filtered by suction 3-x Loaded on the hydrophobically modified CA, after drying, the loaded MoO 3-x composite film.

Embodiment 2

[0036] Preparation loaded with g-C 3 N 4 Composite film:

[0037] Put 10g of urea in a crucible with a lid, keep it warm in a muffle furnace at 550°C for 3 hours, wash and dry it repeatedly with distilled water to obtain light yellow g-C 3 N 4 ; Hydrophobic modification of cellulose acetate membrane was carried out with 300 μL fluorosilane, and dried at 80 °C after modification; 20 mg g-C 3 N 4 Dispersed in water, the g-C was vacuum filtered 3 N 4 Loaded on the hydrophobically modified CA, after drying, the g-C 3 N 4 composite film.

Embodiment 3

[0039] Preparation of MoO of the present invention 3-x / g -C 3 N 4 Composite photocatalytic materials:

[0040] Calcinate 10g of ammonium molybdate tetrahydrate at 500°C for 4h, wash and dry to obtain molybdenum trioxide MoO 3 , the 1g MoO 3 Disperse in 30mL of deionized water, add 4g of chitosan to the deionized water, stir for 30min and then ultrasonic for 30min, mix well, transfer the mixture to the reactor and react at 180°C for 8h; after the reaction, filter the reaction solution , to obtain a solid product, the solid product was washed and dried to obtain MoO 3-x ;Put 10g of urea in a crucible with a lid, keep it warm in a muffle furnace at 550°C for 3h, wash and dry it repeatedly with distilled water to obtain light yellow g-C 3 N 4 ;

[0041] 0.8g g-C 3 N 4 and 0.04g MoO 3-x Disperse in 50mL of ethanol and sonicate for 2 hours, then evaporate the mixed material at 75°C to remove ethanol by magnetic stirring, and then dry at 100°C for 12 hours to obtain the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com