Catalyst for hydrogenation of ester, preparation method and application thereof

A technology for hydrogenation of catalysts and esters, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of less side reactions, high pressure, low space velocity, etc., and achieve less side reactions and high selectivity High, high airspeed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

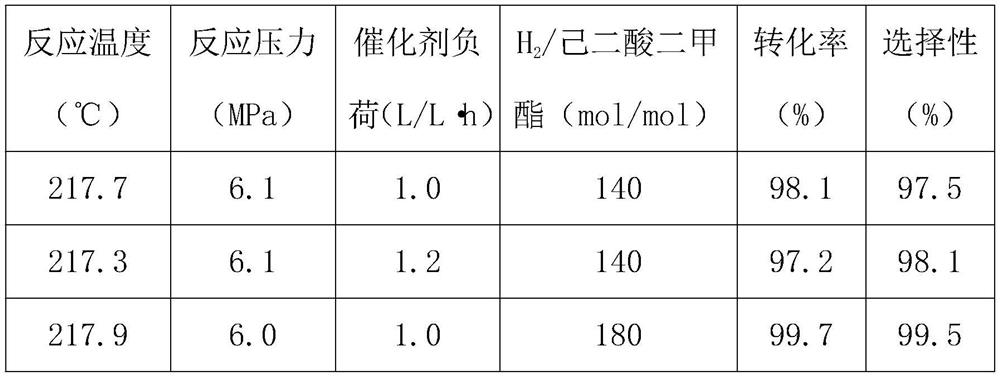

Embodiment 1

[0034] Dissolve 83.02g of sodium hydroxide (NaOH) in 2100ml of distilled water to form an alkaline solution. 17.92g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) Dissolve in 48ml of distilled water, add the alkali solution dropwise to the aluminum nitrate solution under heating and stirring, until the pH value of the solution reaches 8, stop the dropwise addition, leave to age for 0 hour, and obtain the suspension A. 81.58g zinc chloride (ZnCl 2 ) and 600ml of water are added into the suspension A, and the zinc chloride solution is evenly stirred. Under heating and stirring, the alkali solution is added dropwise to the mixed solution until the pH value of the solution reaches 8, and the dripping is stopped. Standing and aging for 4 hours, suspension B was obtained. 75.39g copper acetate (C 4 h 6 CuO 4 ·H 2 O) the copper acetate solution that 377ml water is made into joins in the suspension B, stirs, and under heating and stirring condition, alkali solution is added dropwise in...

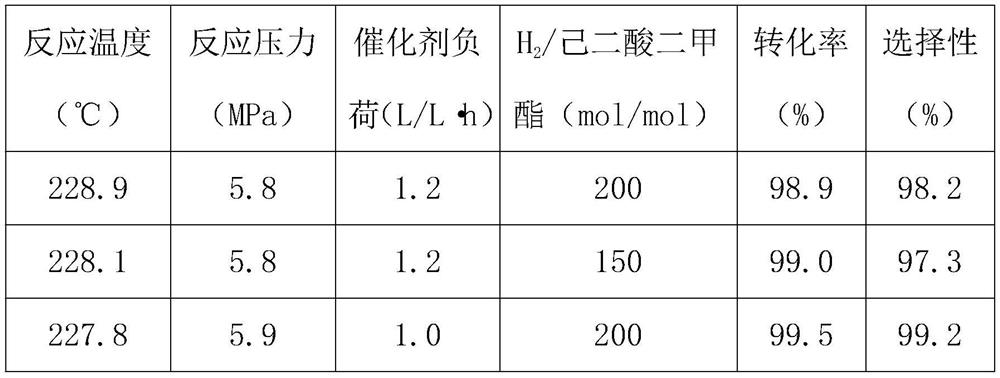

Embodiment 2

[0036] 60.29g sodium hydroxide (NaOH) and 79.88g sodium carbonate (NaOH) 2 CO 3 ) was dissolved in 2260ml of distilled water to prepare an alkaline solution. 122.58g aluminum chloride (AlCl 3 ·6H 2 O) be dissolved in 507ml of distilled water, under the condition of heating and stirring, the alkali solution is added dropwise in the aluminum chloride solution, until the pH value of the solution reaches 8, stop the dropwise addition, leave it to stand and age for 4 hours to obtain the suspension A. 157.55g zinc nitrate (N 2 o 6 Zn·6H 2 0) The zinc nitrate solution made with 530ml water joins in the suspension A, stirs, under heating and stirring condition, alkali solution is added dropwise in this mixed solution, until the solution pH value reaches 8, stop dripping, Standing and aging for 4 hours, suspension B was obtained. 52.36g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) the copper nitrate solution that 217ml water is made into joins in the suspension B, stirs, and under he...

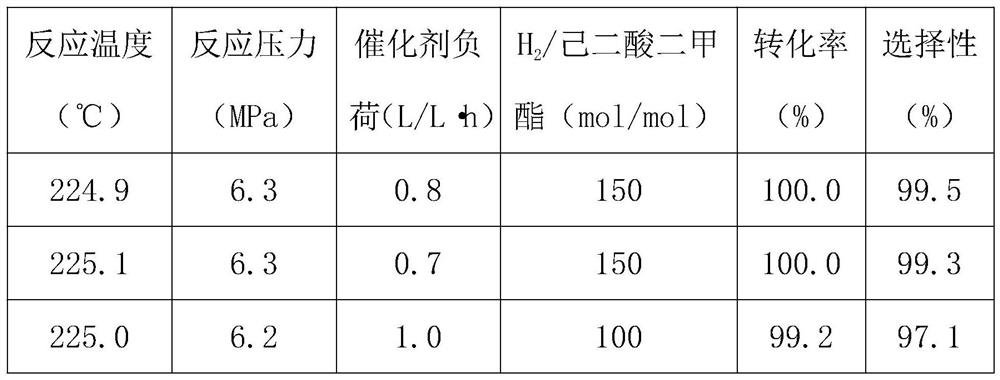

Embodiment 3

[0038] 140.67g sodium carbonate (Na 2 CO 3 ) was dissolved in 1330ml of distilled water to form an alkaline solution. 26.52g basic aluminum acetate (Al(OH)C 4 h 6 o 4 ) and 13.26g aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 O) Dissolve in 203ml of distilled water, add the alkali solution dropwise to the aluminum salt solution under the condition of heating and stirring until the pH value of the solution reaches 8, stop the dropwise addition, leave it to stand and age for 2 hours to obtain the suspension A. 22.49g zinc acetate (C 4 h 6 o 4 Zn·2H 2 O) the zinc salt solution that 103ml water is made into joins in the suspension A, stirs, and under heating and stirring condition, alkali solution is added dropwise in this mixed solution, until the solution pH value reaches 8, stop dripping, Standing and aging for 0 hour, suspension B was obtained. 117.14g copper sulfate (CuSO 4 ) and 734ml of water were added into the suspension B, and stirred evenly. Under heating and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com