Method for preparing boehmite modified cationic adsorbent

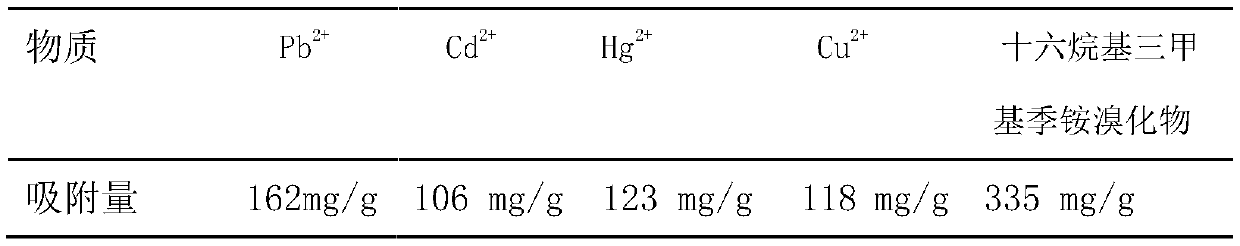

A technology of cation adsorption and boehmite, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of boehmite’s weak adsorption capacity for cations and cannot be recycled and recycled, and achieve easy Recovery and regeneration, fast adsorption rate and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

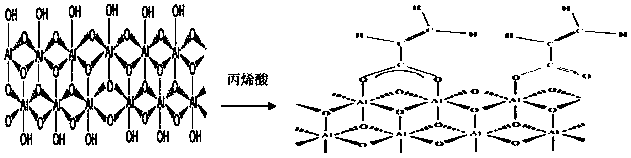

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a boehmite modified cationic adsorbent, the method comprising the steps of:

[0032] (1) Add 6.49g of sodium hydroxide to 50ml of water to form a 3.24M sodium hydroxide solution, and then drip it at a rate of 2.94ml per minute into 30ml of aluminum chloride aqueous solution with an aluminum ion concentration of 1.78M under vigorous stirring. Add sodium hydroxide solution, drop it completely in about 17 minutes, then ultrasonicate at 25°C for 3 hours, precipitate, filter and wash with water, and finally bake at 220°C for 4 hours to obtain boehmite.

[0033] (2) Get 50 grams of boehmite (0.83mol) and add it to 800 milliliters of distilled water to disperse, and carry out ultrasonic treatment, add 3 grams of hydroquinone after 5 minutes; Then slowly add methacrylic acid (154g, 1.8 mol), the reaction was carried out under stirring at 70°C for 20 hours, the solid product was washed with deionized water, and finally dried in vacuum at 50°C for 20 hours ...

Embodiment 2

[0037] A method for preparing a boehmite modified cationic adsorbent, the method comprising the steps of:

[0038] (1) Dissolve 10.2g of sodium metaaluminate and 28.8g of urea in 1L of deionized water, then pipette 30mL of sodium metaaluminate / urea mixed solution into a 50mL hydrothermal reaction kettle, and place it in an oven at 160°C Perform hydrothermal reaction for 24 hours, cool, wash, filter and dry to obtain boehmite.

[0039](2) Disperse 10.0g of boehmite in 250mL of xylene, add 48g of acrylic acid, reflux the mixture in xylene at 138-145°C for 72 hours, distill under reduced pressure to remove toluene, wash the solid with ether to remove impurities, and obtain white after drying Esterified boehmite powder.

[0040] (3) Add 20.6g sodium p-styrenesulfonate, 0.2g diethylenetriamine and 5g esterified boehmite powder to 500mL of water, pass nitrogen gas for 15 minutes, add 0.1g potassium persulfate and nitrogen gas, stir, React at 70-80°C for 5 hours, then wash with wat...

Embodiment 3

[0042] A method for preparing a boehmite modified cationic adsorbent, the method comprising the steps of:

[0043] (1) Take 6.0g of commercial boehmite, add 250mL of water to disperse, add 11.6g of butenedioic acid, stir and heat in xylene at 138-145°C for 24 hours, filter, wash with ethanol, and dry at 80°C Esterified boehmite was obtained.

[0044] (2) Use 12g of polyvinylidene fluoride, 5g of ferric oxide, 5g of esterified boehmite, 3g of polyvinylpyrrolidone and 75g of dimethyl sulfoxide at 60°C for 12 hours to make a solution, and then add it dropwise to distilled water to condense Glue for 24 hours to obtain polymer microspheres, drain and soak in ethanol for 1 hour, and dry in air to obtain esterified boehmite polymer microspheres.

[0045] (3) with 500 milliliters of aqueous solution preparation containing 3wt% acrylic acid and 3wt% sodium p-styrene sulfonate, add 0.7g ethylene glycol, logical nitrogen 15 minutes, add the polymer microsphere containing 10g esterified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com