Lithium ion battery with high energy density

A lithium-ion battery, high energy density technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of low reversible capacity, limited use, too fast decay of voltage platform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

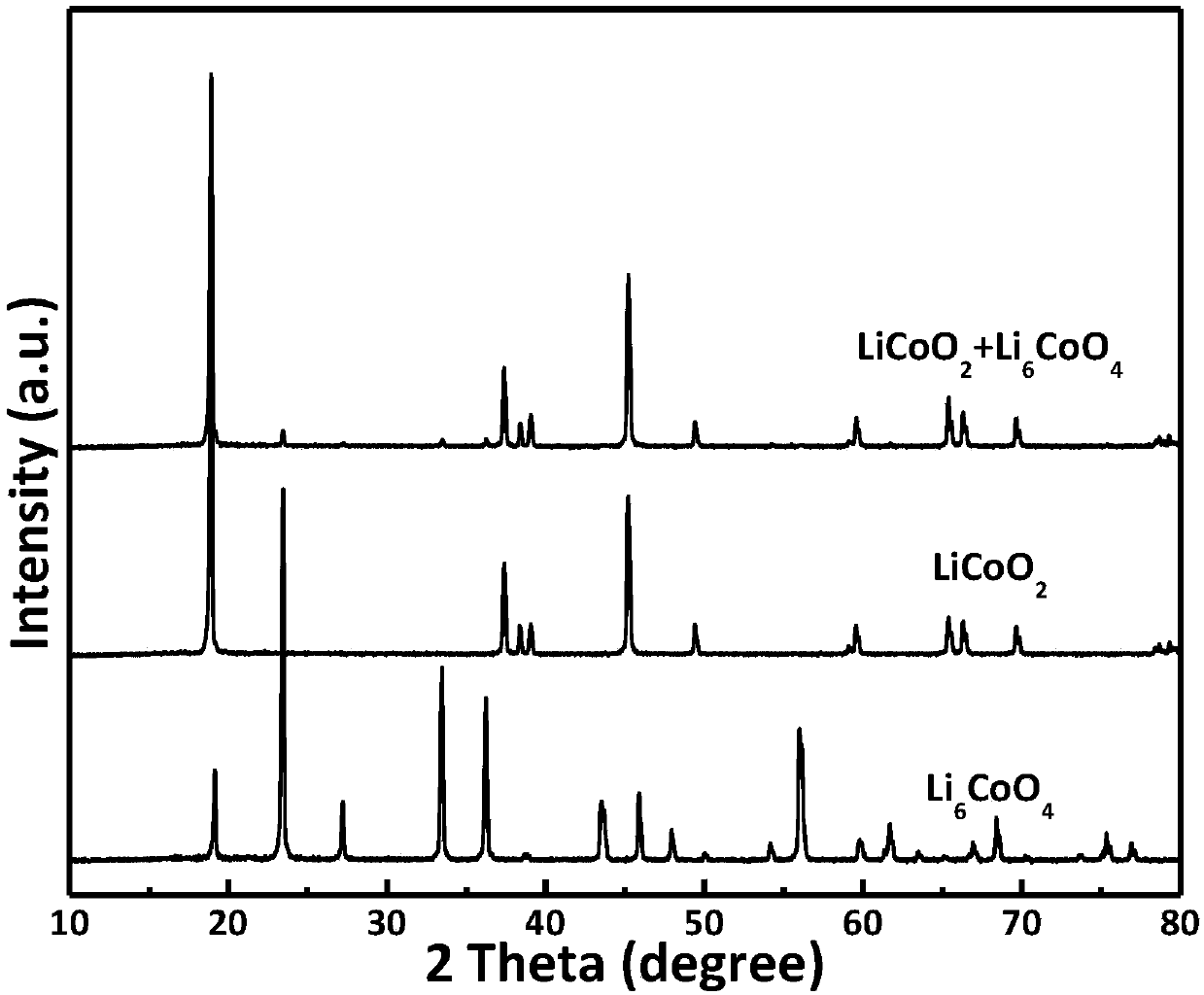

[0096] Weigh Li 2 O 508.0g, LiH 16.0g, add ball milling beads according to the ratio of ball to material 4:1, use a ball mill to grind for 30min, add Co 3 o 4 476.8g, add 3.5g of Al 2 o 3 At the same time, the corresponding ball-milling beads were supplemented according to the ball-to-material ratio of 4:1, and ball milling was continued for 30 minutes to obtain evenly mixed Li 2 O, LiH, Co 3 o 4 and Al 2 o 3 mixture. The obtained material was placed in an electric furnace at a constant temperature of 400° C. for 24 h under an argon atmosphere. After free cooling to room temperature, it was taken out, ground and sieved to obtain a lithium-rich cobalt oxide (Li 6 co 0.99 Al 0.01 o 4 ).

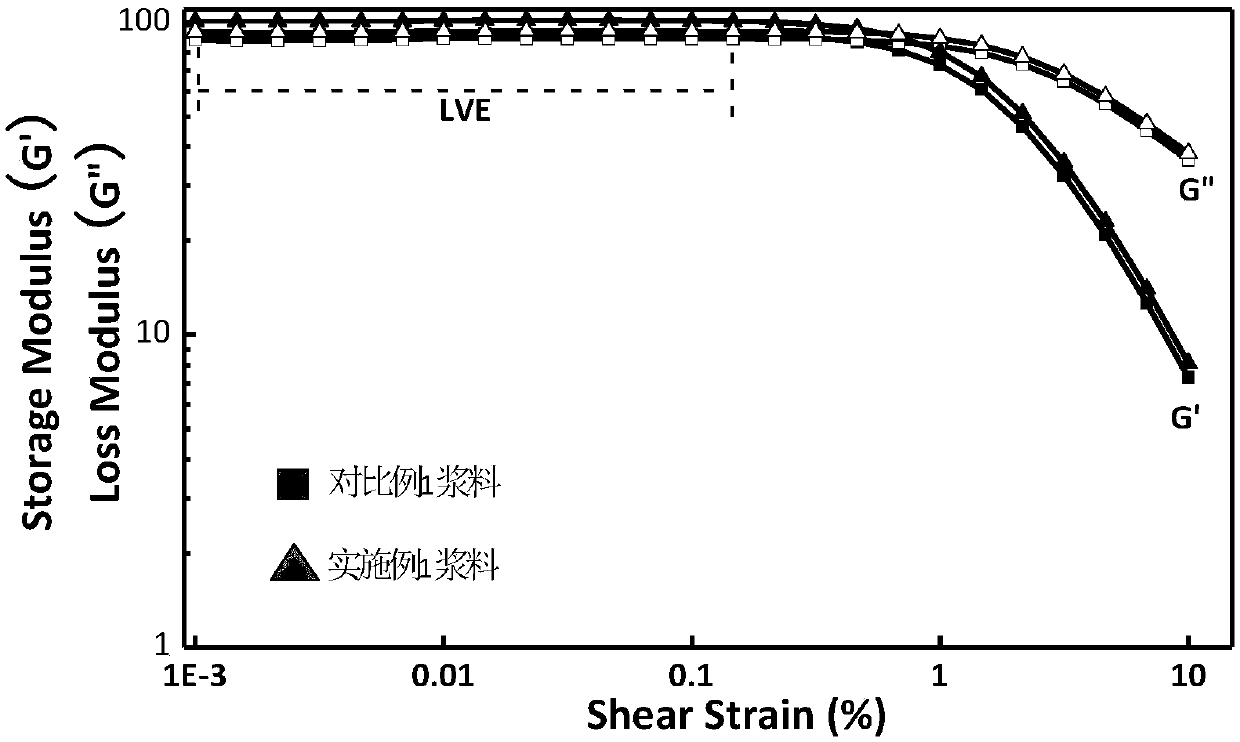

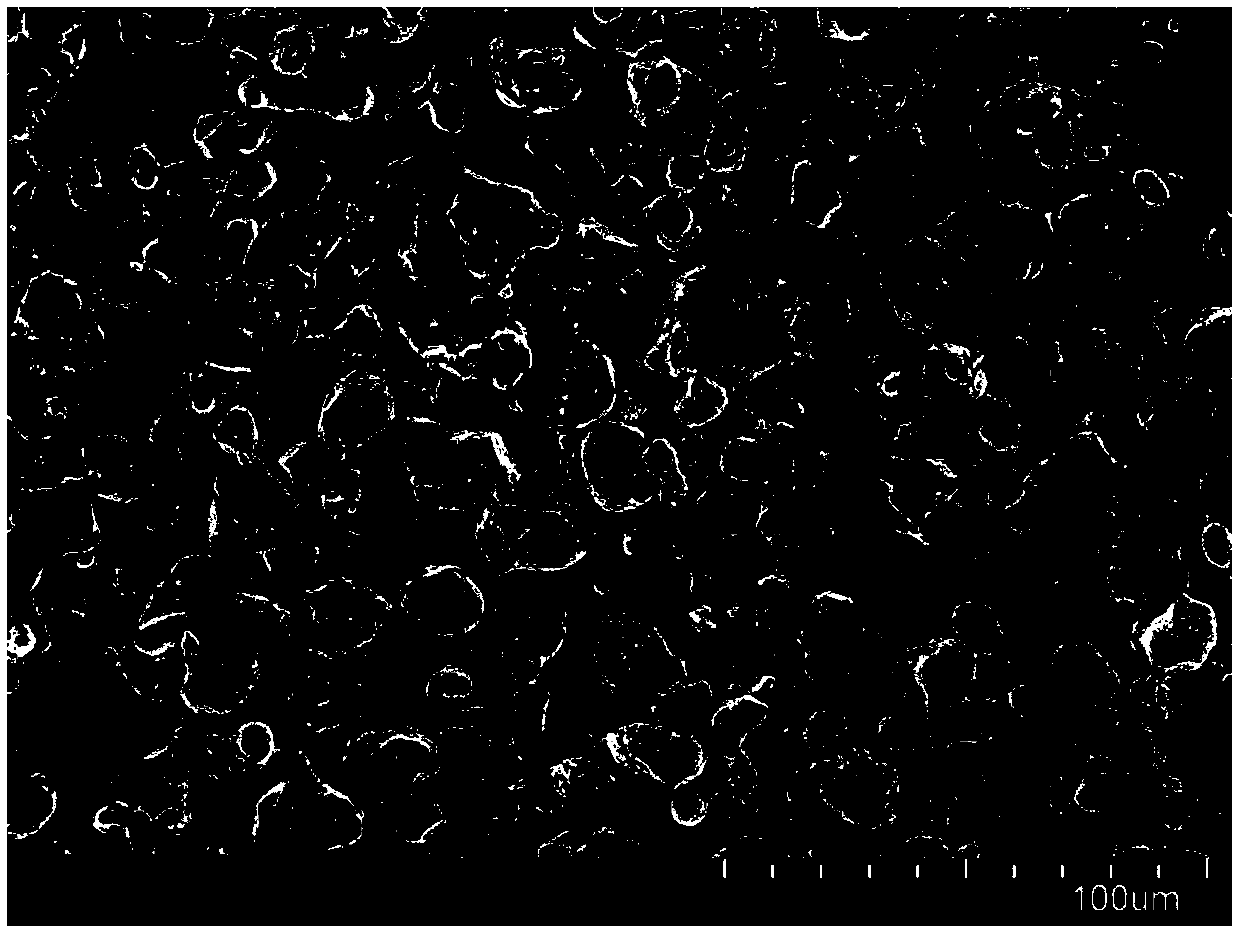

[0097] The positive electrode active material nickel-cobalt-manganese ternary material (Li(Ni 0.5 mn 0.3 co 0.2 )O 2 ), a lithium-rich cobalt oxide material (Li 6 co 0.99 Al 0.01 o 4 ) mixed with conductive agent multi-layer graphene and thickener / binder polyvinylidene flu...

Embodiment 2

[0104] Weigh Li 2 O 508.0g, LiH 16.0g, add ball milling beads according to the ratio of ball to material 4:1, use a ball mill to grind for 30min, add Co 3 o 4 481.6g, supplement corresponding ball-milling beads by ball-to-material ratio 4:1 simultaneously, continue ball-milling 30min, obtain the evenly mixed Li 2 O, LiH and Co 3 o 4 mixture. The obtained material was placed in an electric furnace at a constant temperature of 900° C. for 12 h under an argon atmosphere. Obtain the first product after natural cooling, put into the ball mill after the first product is crushed, weigh the Al at the same time 2 o 3 20.1g was added to the ball mill jar. Add ball milling beads according to the ball-to-material ratio of 6:1, and mill for 20 minutes. Put the material into an electric furnace and keep the temperature at 700° C. for 4 hours under an argon atmosphere. After free cooling to room temperature, it was taken out, ground and sieved to obtain a lithium-rich cobalt oxide...

Embodiment 3

[0113] Weigh Li 2 O 268.9g, add ball milling beads according to the ball-to-material ratio of 4:1, use a ball mill to grind for 30min, add CoO2 20.3g, weigh ZnO 2.5g, TiO 2 2.3g, at the same time supplement the corresponding ball milling beads according to the ball-to-material ratio of 4:1, and continue the ball milling for 30min to obtain evenly mixed Li 2 O, CoO, ZnO, and TiO 2 mixture. The obtained material was placed in an electric furnace at a constant temperature of 1000° C. for 10 h under an argon atmosphere. Obtain the first product after natural cooling, put into the ball mill after the first product is crushed, weigh the Al at the same time 2 o 3 Add 0.2g into the ball mill jar. Add ball milling beads according to the ball-to-material ratio of 6:1, and mill for 20 minutes. Put the material into an electric furnace and keep the temperature at 600° C. for 4 hours under an argon atmosphere. After free cooling to room temperature, it was taken out, ground and sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com