Method for recycling soluble textiles

A textile and solution technology, applied in the fields of environmental protection, textile processing, and fiber processing, can solve the problems of non-dissolving fiber damage, affecting fiber recycling, and slow dissolution of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

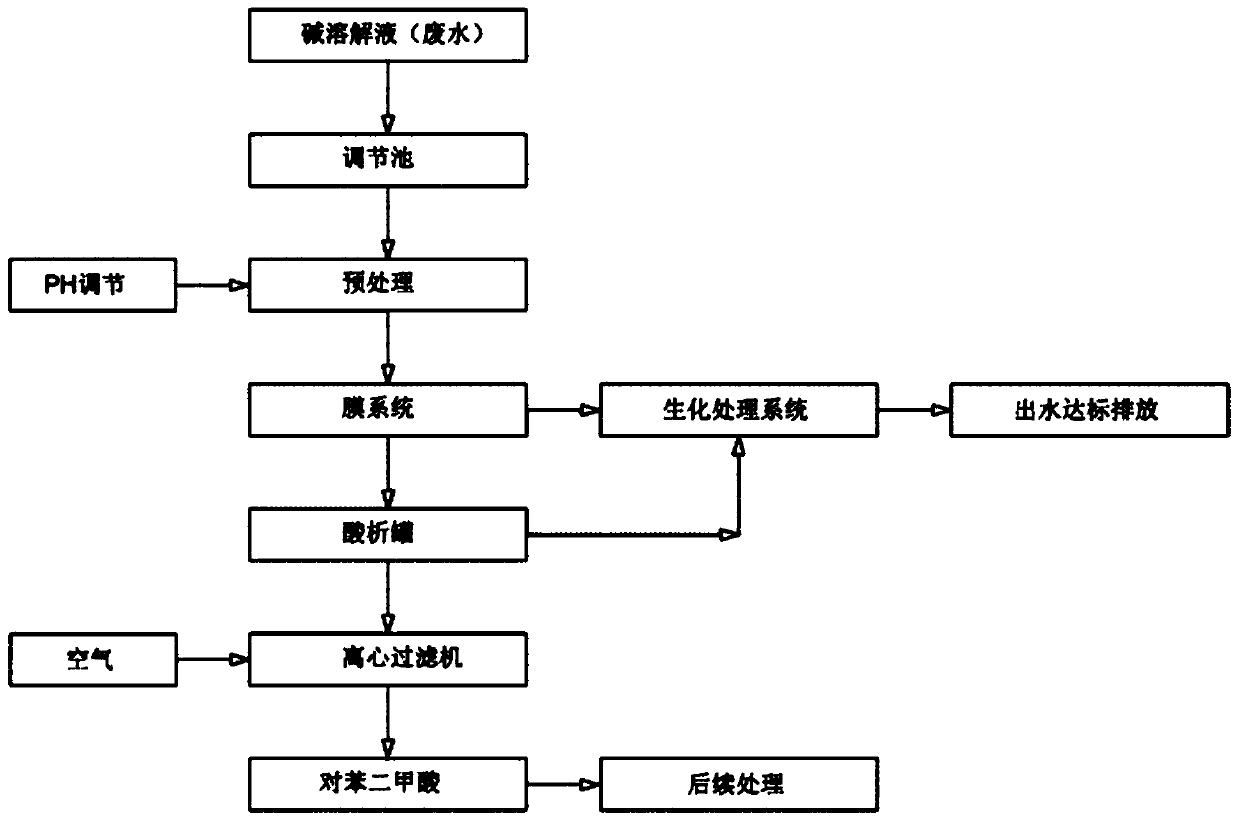

[0070] 100% controllable soluble fiber fabrics and the dissolution, recycling and reuse technology of soluble clothing accessories, which include the following process steps, specifically:

[0071] a. In the polyester raw material polymerization process, add the 5-sodium sulfonate-polyethylene glycol isophthalate and the isophthalic acid of 4% in the total weight of the polymer, beating and stirring And heat up to 230°C at the same time; then move to the reactor and add polyethylene glycol with a total polymer weight of 10% to dilute it and cool it down to 210°C; continue to add polyethylene glycol to the reactor, this Part of the polyethylene glycol accounts for 10% of the total weight of the polymer. The polyethylene glycol is added within 50 minutes and stirred at the same time. The temperature is raised to 230°C under normal pressure and the mixed material is polymerized in a vacuum state. The alkali after polymerization is degraded. Finally, the slices are cast, cooled, p...

Embodiment 2

[0079] Dissolution, recovery and reuse technology of controllable soluble fiber and cellulose fiber blended yarn fabric and soluble clothing accessories, which includes the following process steps, specifically:

[0080]a. The controllable soluble fiber staple prepared in Example 1 is blended with cellulose fibers (such as cotton, hemp and rayon), and the blending ratio is 65 / 35, 50 / 50, etc.; Cellulose fiber or blended yarn specifications; weaving according to conventional processes; dyeing with reactive dyes and disperse dyes in two baths of polyester and cellulose fibers; thus, fabrics, including woven and knitted fabrics;

[0081] (1) After the above-mentioned staple fiber blended yarn is plyed and threaded, it can be used as sewing thread for such textiles;

[0082] (2) The above-mentioned garments and textiles are paired with apparel accessories, which are rigid soluble apparel accessories that have undergone conventional injection molding, masterbatch coloring and moldin...

Embodiment 3

[0087] Controllable dissolving, recycling and recycling technology of blended yarn of soluble fiber and cellulose fiber plus spandex fiber fabric and soluble clothing accessories, which includes the following process steps, specifically:

[0088] a. The polymerized raw material prepared in Example 1 is subjected to a conventional spinning process to produce short fibers (3.6cn / dtex strength, 25% elongation at break) with a length of 38mm and a fineness of 1.5D, which will be controllable Soluble fiber short fiber, blended with cellulose fiber (such as cotton, hemp and artificial fiber), the blending ratio is 65 / 35, 50 / 50, etc., the yarn is interwoven with spandex or parallel elastic yarn, according to the conventional weaving process Woven or knitted fabrics; polyester and cellulose fibers are dyed with reactive dyes and disperse dyes in two baths; thus, fabrics, including woven and knitted fabrics, are sewn into finished textiles;

[0089] (1) After the above-mentioned staple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com