Static anti-fouling self-layering organosilicon coating and preparation method and application thereof

A silicone coating and self-layering technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of inability to play antifouling effect, achieve excellent antifouling ability and reduce surface energy , Excellent fouling and desorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

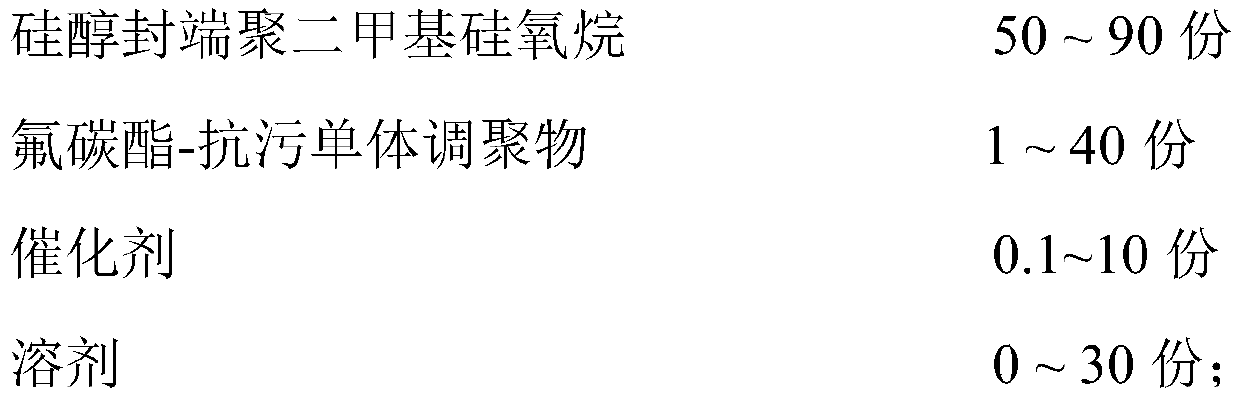

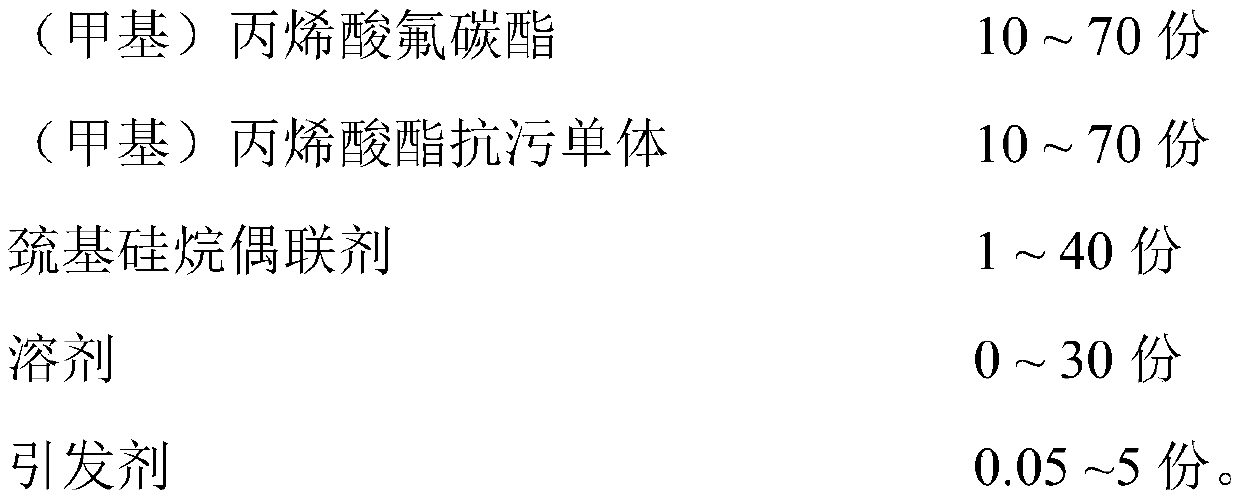

[0056] 1. In the reaction vessel, add 70 parts by weight of hexafluorobutyl acrylate, 25 parts by weight of polyethylene glycol methacrylate with a degree of polymerization of 10, and 4 parts by weight of mercaptomethyltrimethoxysilane (purchased from Gelest Company) 1. 1 part by weight of benzoyl peroxide was reacted at 120° C. for 12 hours to obtain a fluorocarbon ester-antifouling monomer telomer with a molecular weight of 2500 g / mol.

[0057] 2. In the reaction vessel, add 50 parts by weight of silanol-terminated polydimethylsiloxane (viscosity is 5000mPa·s), 40 parts by weight of the fluorocarbon ester-antifouling monomer telomer prepared in step 1, 9 Parts by weight of xylene and 1 part by weight of dibutyltin dilaurate were stirred at room temperature for 10 minutes, sprayed on the steel plate, and cured at room temperature for 1 day to obtain a coating. The elastic modulus of the coating is 2.3MPa. The shallow sea hanging board test was carried out on the coating, and...

Embodiment 2

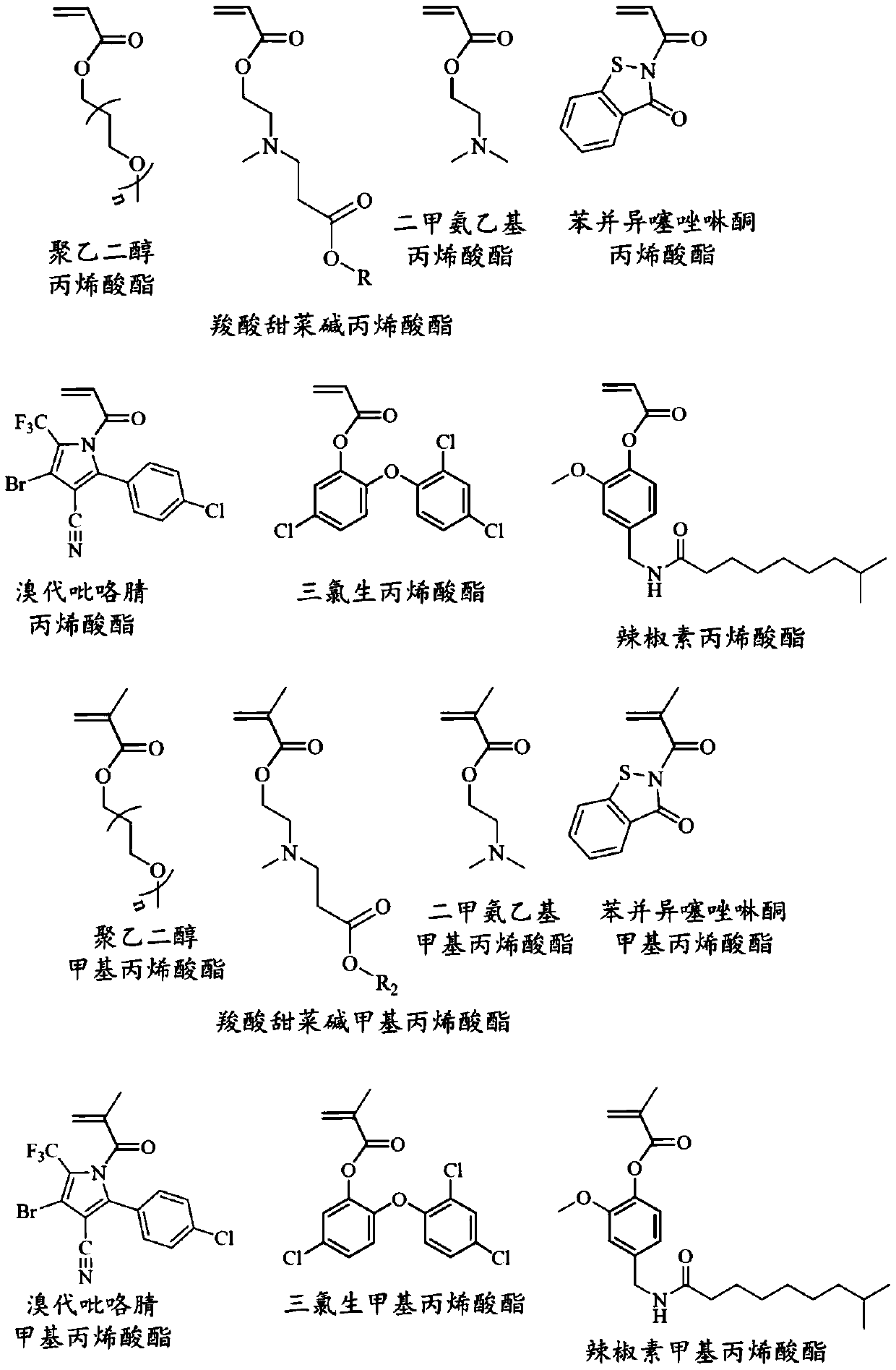

[0059] 1. In a reaction vessel, add 10 parts by weight of trifluoroethyl acrylate and 70 parts by weight of ethyl carboxybetaine acrylate (the structural formula is as described in formula 1, wherein R is C 2 h 4 ), 1 part by weight of mercaptopropyltrimethoxysilane, 0.05 parts by weight of azobisisobutyronitrile, and 18.95 parts by weight of acetone, reacted for 48 hours at 60 ° C to obtain fluorocarbon ester-antifouling monomer telomer, molecular weight is 10000g / mol;

[0060]

[0061] 2. In the reaction vessel, add 90 parts by weight of silanol-terminated polydimethylsiloxane (viscosity is 500mPa·s), 1 part by weight of fluorocarbon ester-antifouling monomer telomer prepared in step 1, 9 parts by weight Parts by weight of tetraethyl orthosilicate and 0.1 part by weight of di-n-octyltin dilaurate were stirred at room temperature for 30 minutes, sprayed on the steel plate, and cured at room temperature for 1 day to obtain a coating. The elastic modulus of the coating is ...

Embodiment 3

[0063] 1. In a reaction vessel, add 10 parts by weight of octafluoropentyl methacrylate, 8 parts by weight of dodecafluoroheptyl acrylate, 10 parts by weight of dimethylaminoethyl methacrylate (purchased from Sigma Aldrich), 40 parts by weight Mercaptomethyltriethoxysilane (purchased from Sigma Aldrich), 2 parts by weight of phosphazene salt (purchased from Sigma Aldrich) and 30 parts by weight of isopropanol were reacted at 50°C for 24 hours to obtain fluorocarbon ester-antifouling Monomer telomer with a molecular weight of 1000 g / mol.

[0064] 2. In the reaction vessel, add 65 parts by weight of silanol-terminated polydimethylsiloxane (viscosity is 3000mPa·s), 5 parts by weight of fluorocarbon ester-antifouling monomer telomer prepared in step 1, 20 parts by weight Parts by weight of tetrapropyl orthosilicate and 10 parts by weight of acetic acid were sprayed on the steel plate after being stirred at room temperature for 10 minutes, and cured at room temperature for 3 days t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com