Anti-fouling organic-inorganic silicon hybrid paint and production method and application thereof

An inorganic silicon and organic technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. The problem of being scratched, etc., achieves the effects of excellent antifouling ability, simple and feasible preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

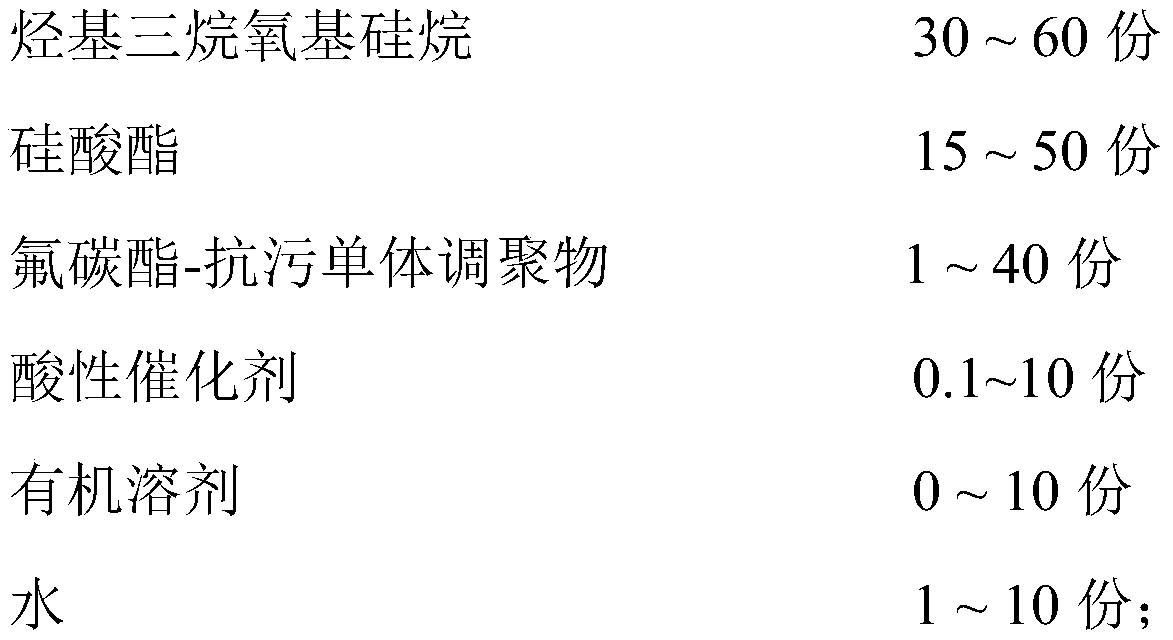

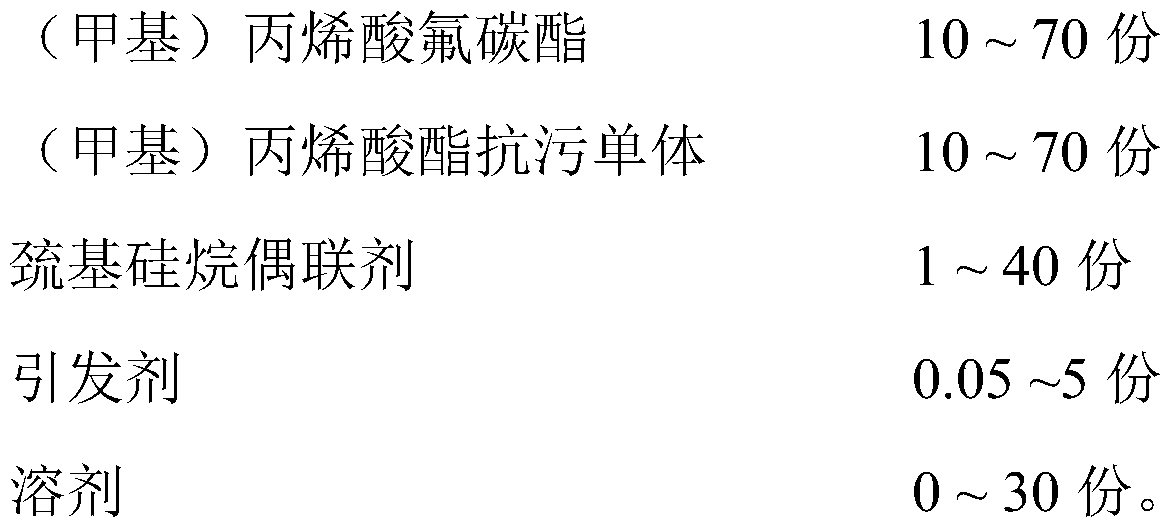

Method used

Image

Examples

Embodiment 1

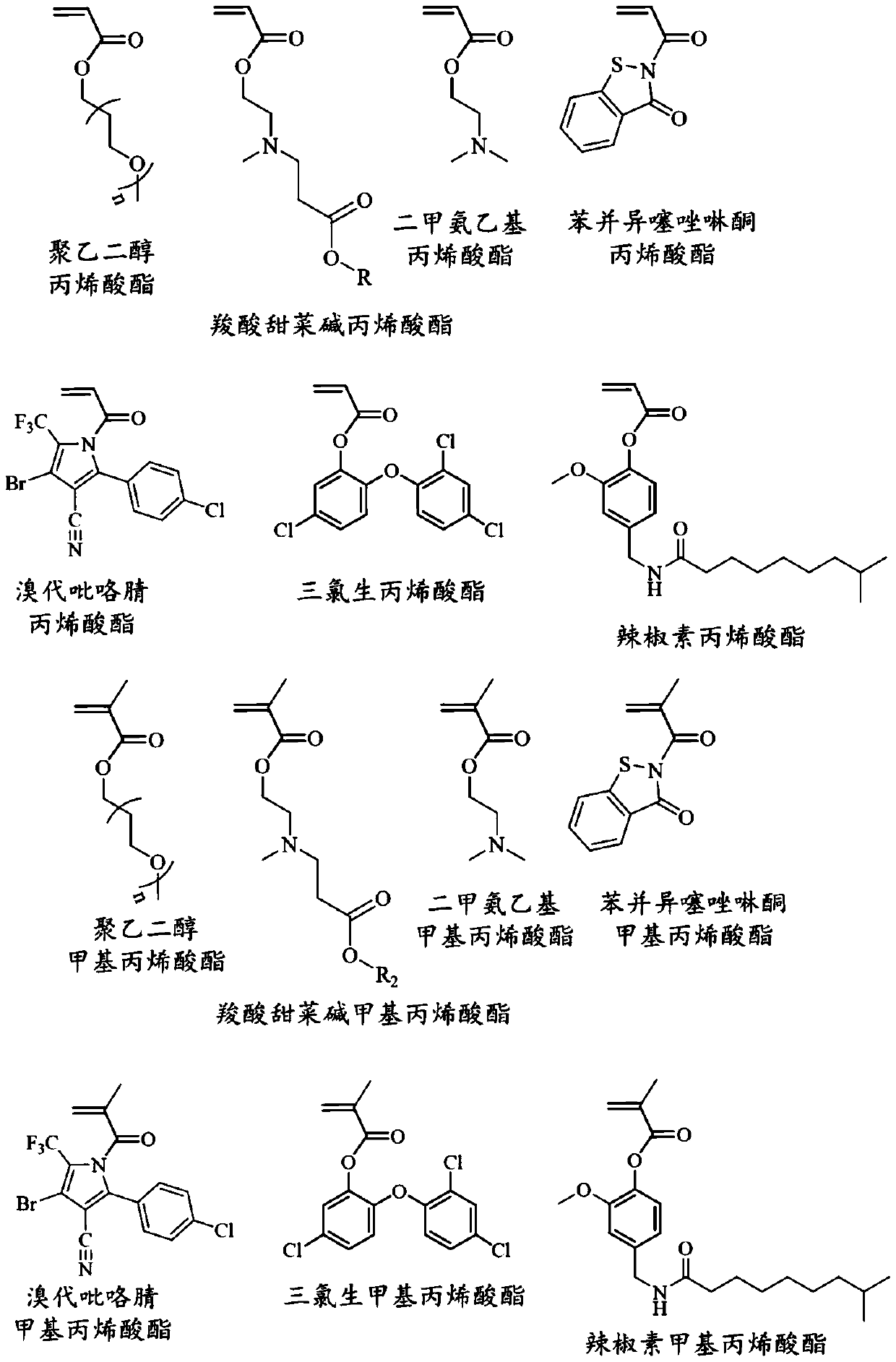

[0050] 1. In a reaction vessel, add 70 parts by weight of hexafluorobutyl acrylate, 25 parts by weight of polyethylene glycol methacrylate with a degree of polymerization of 10, 4 parts by weight of mercaptomethyltrimethoxysilane, 1 part by weight of peroxide Benzoyl was reacted at 120°C for 12 hours to obtain a fluorocarbon ester-antifouling monomer telomer with a molecular weight of 2500 g / mol.

[0051] 2. In the reaction vessel, add 30 parts by weight of methyltriethoxysilane, 10 parts by weight of the fluorocarbon ester-anti-fouling monomer telomer prepared in step 1, 50 parts by weight of methyl orthosilicate, 2 parts by weight Hydrochloric acid solution (aqueous solution with a concentration of 0.1 mol / L), 8 parts by weight of deionized water, stirred at room temperature for 4 hours, coated on an epoxy board, and cured at room temperature for 2 days to obtain a coating. The paint film adhesion of the obtained coating is 2.4MPa, the pencil hardness is H, and the coating h...

Embodiment 2

[0053] 1. In a reaction vessel, add 10 parts by weight of trifluoroethyl acrylate and 70 parts by weight of ethyl carboxybetaine acrylate (the structural formula is as described in formula 1, wherein R is C 2 h 4 ), 1 part by weight of mercaptopropyltrimethoxysilane, 0.05 parts by weight of azobisisobutyronitrile, and 18.95 parts by weight of acetone, reacted for 48 hours at 60 ° C to obtain fluorocarbon ester-antifouling monomer telomer, molecular weight is 10000g / mol;

[0054]

[0055] 2. In the reaction vessel, add 30 parts by weight of octyltriethoxysilane, 10 parts by weight of the fluorocarbon ester-anti-fouling monomer telomer prepared in step 1, 50 parts by weight of tetraethyl orthosilicate, 0.1 parts by weight Nitric acid solution (aqueous solution with a concentration of 0.1 mol / L), 9.9 parts by weight of deionized water, stirred at room temperature for 48 hours, coated on an epoxy board, and cured at room temperature for 3 days to obtain a coating. The paint f...

Embodiment 3

[0057] 1. In a reaction vessel, add 10 parts by weight of octafluoropentyl methacrylate, 8 parts by weight of dodecafluoroheptyl acrylate, 10 parts by weight of dimethylaminoethyl methacrylate, 40 parts by weight of mercaptomethyltriethyl Oxysilane, 2 parts by weight of phosphazene salt, and 30 parts by weight of isopropanol were reacted at 50° C. for 24 hours to obtain a fluorocarbon ester-antifouling monomer telomer with a molecular weight of 1000 g / mol.

[0058] 2. In the reaction vessel, add 35 parts by weight of octyltriethoxysilane, 20 parts by weight of phenyltriethoxysilane, 10 parts by weight of the fluorocarbon ester-antifouling monomer telomer prepared in step 1, 15 parts by weight Parts by weight of tetraethyl orthosilicate, 10 parts by weight of acetic acid solution (aqueous solution with a concentration of 0.05mol / L), 10 parts by weight of deionized water, stirred at room temperature for 24 hours, coated on an epoxy board, cured at room temperature for 1 day to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com