A kind of preparation method of nano-iron powder material with continuous controllable activity

A nano-iron powder, sustainable technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of not taking into account the sustainability of nano-iron powder activity, and achieves low cost and solution. Agglomeration, process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the activity-sustainable nano-iron powder material in this embodiment includes the following steps:

[0023] (1) In a gas atmosphere other than oxygen and under stirring conditions, add 0.25g of acrylonitrile-butadiene-styrene terpolymer and 0.0025g of ethyl cellulose into 60mL of ethyl acetate, stir at 300rpm Under, fully dissolve acrylonitrile-butadiene-styrene terpolymer and ethyl cellulose;

[0024] (2) Get 0.25g of nano-iron powder and join in the polymer ethyl acetate solution in step (1), and disperse evenly under sufficient stirring conditions to obtain a mixed solution of nano-iron powder and polymer ethyl acetate solution;

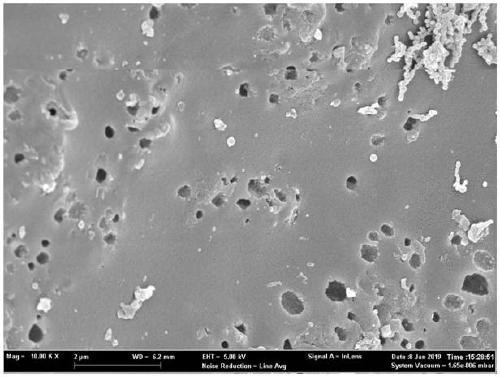

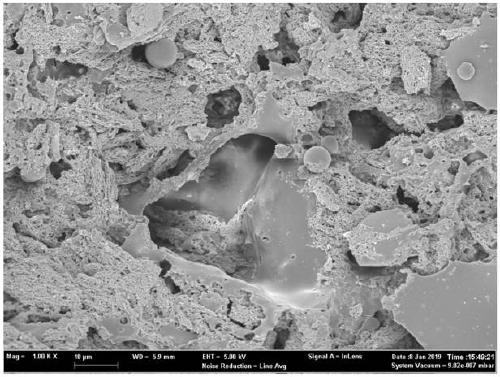

[0025] (3) Add 60 mL of polyethylene glycol 400 dropwise to the mixed solution obtained in step (2), causing phase separation of acrylonitrile-butadiene-styrene terpolymer and ethyl cellulose, and wait until the dropwise addition is completed Finally, add 250ml of n-heptane, stop stirring, and after standing stil...

Embodiment 2

[0030] The preparation method of the activity-sustainable nano-iron powder material in this embodiment includes the following steps:

[0031] (1) In a gas atmosphere environment other than oxygen and under stirring conditions, 0.25g of acrylonitrile-butadiene-styrene terpolymer and 0.0025g of ethyl cellulose are added to 60mL of toluene, and at a stirring speed of 300rpm, Fully dissolve acrylonitrile-butadiene-styrene terpolymer and ethyl cellulose;

[0032] (2) Get 0.25g nano-iron powder and join in the polymer toluene solution in step (1), disperse evenly under the sufficient stirring condition, obtain the mixed solution of nano-iron powder and polymer toluene solution;

[0033] (3) Add 60 mL of polyethylene glycol 400 dropwise to the mixed solution obtained in step (2), causing phase separation of acrylonitrile-butadiene-styrene terpolymer and ethyl cellulose, and wait until the dropwise addition is completed Finally, add 250ml of n-heptane, stop stirring, and after standi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com