Method and device for measuring atomization particle size distribution and atomization rate of high-melting-point materials

A particle size distribution and measuring device technology, which is used in the measurement of atomization particle size distribution and atomization rate of high-melting point materials, and the measurement field of atomization particle size distribution and atomization rate, which can solve the problem that the overall spray field cannot be accurately measured. Atomization rate, difficult to identify droplets, errors and other problems, to achieve the effect of solving the overall atomization particle size distribution and the measurement accuracy of the atomization rate, high accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

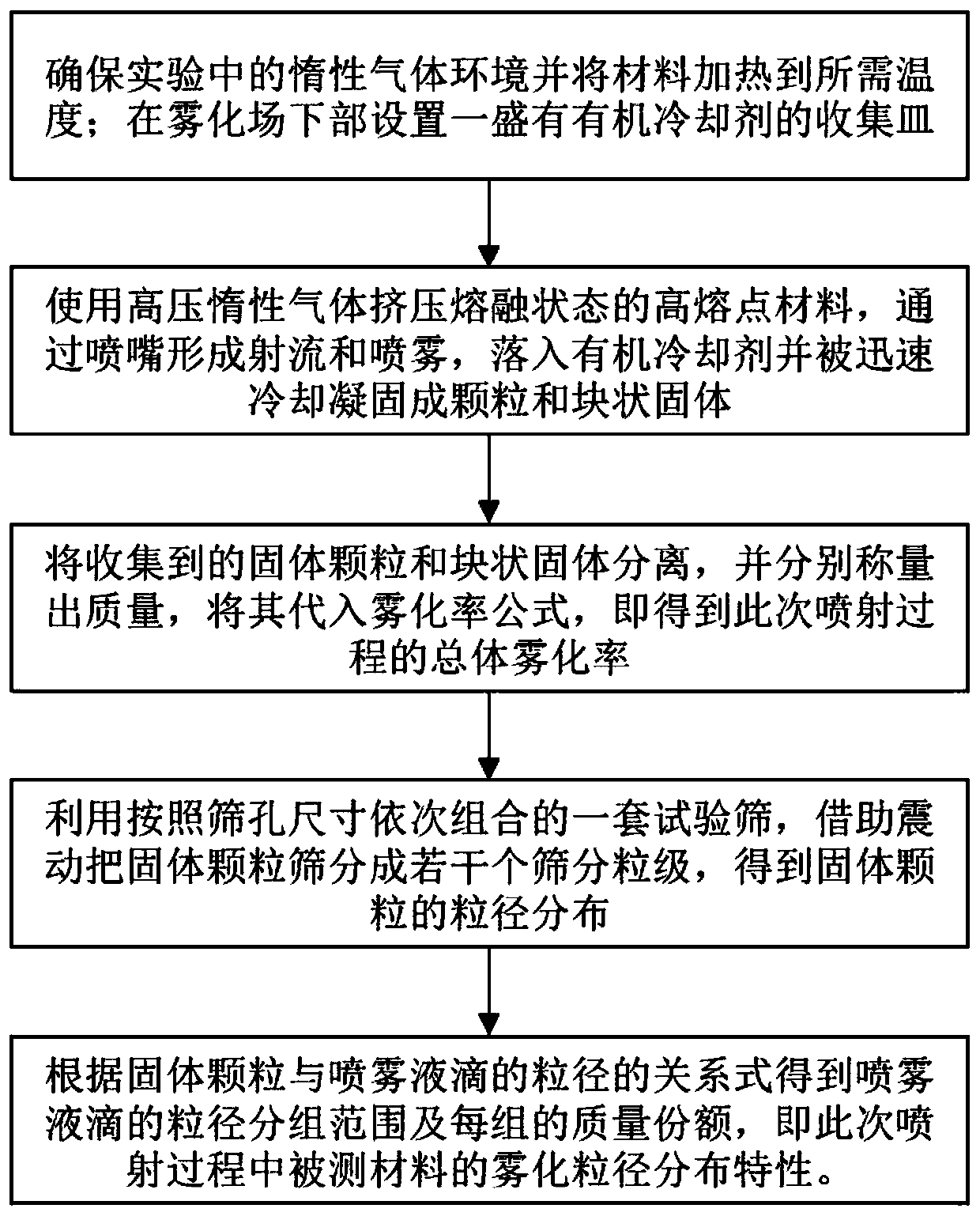

[0032] Embodiment 1. This embodiment provides a method for measuring the atomized particle size distribution and atomization rate of high melting point materials, which includes the following steps:

[0033] (1) Before the spray experiment, it is necessary to ensure the inert gas environment in the experiment to prevent the high melting point material from being oxidized during the spraying process; heat the material to the required temperature T 0 ; Set a collection dish filled with organic coolant in the lower part of the atomization field to collect the falling jets and atomized droplets.

[0034] (2) Use high-pressure inert gas to extrude high-melting-point materials in molten state, form jets and sprays through nozzles, and fall into organic coolant, spray droplets and jets will be rapidly cooled and solidified into particles and massive solids, deposited on the collector dish bottom.

[0035] (3) Separating the collected solid particles and massive solids, and weighing ...

Embodiment 2

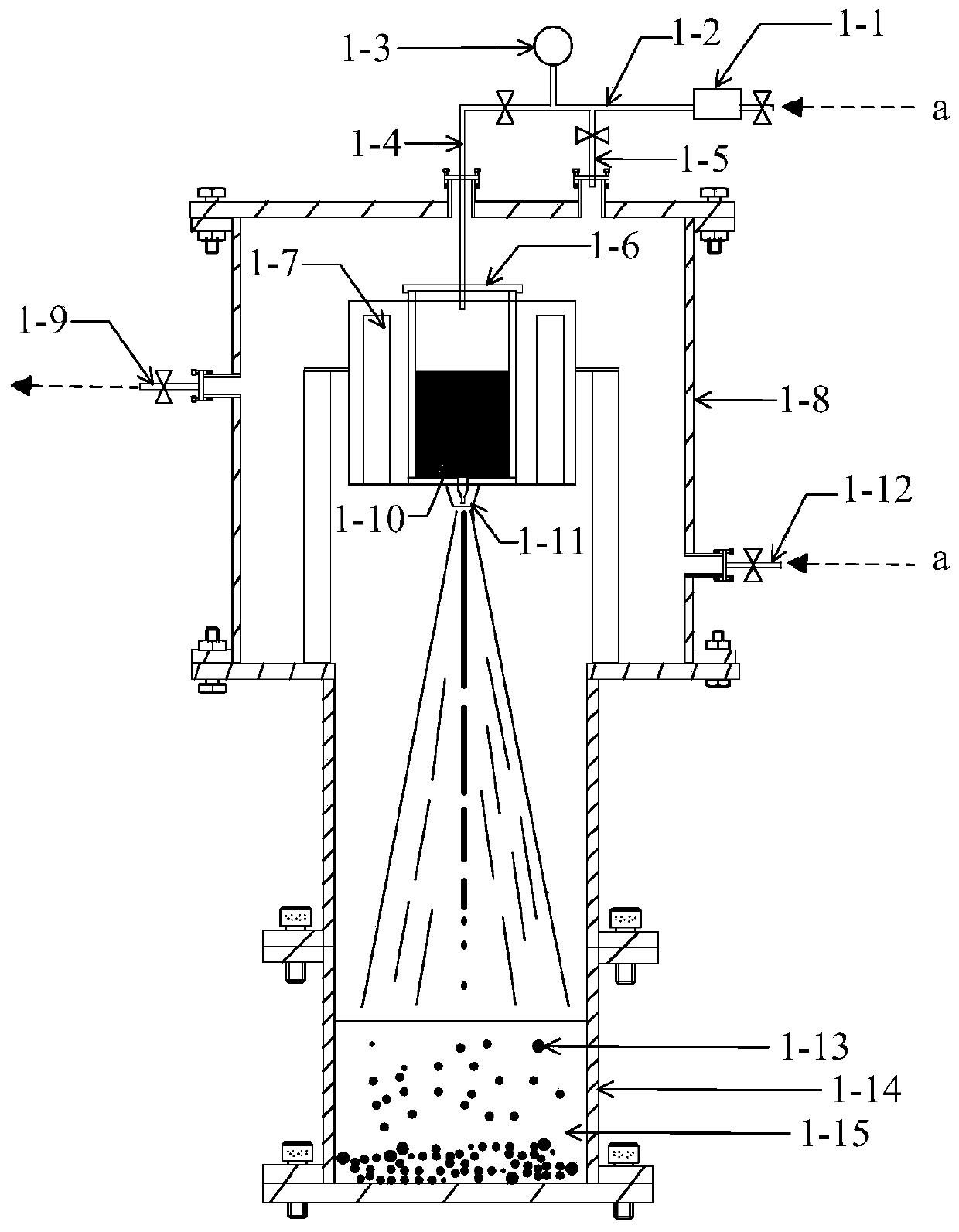

[0040] This embodiment provides a device for measuring atomized particle size distribution and atomization rate of high melting point materials, which includes a closed container 1-8, a sealed crucible 1-6, a heating device 1-7, and a lower collecting vessel 1-14. The closed container 1-8 adopts a structure with a wide top and a narrow bottom. The plane formed in the middle is used to support the sealed crucible 1-6 located in the upper part of the container and the heating device 1-7 around it. The bottom of the crucible 1-6 is provided with an opening. For connection with different types of nozzles 1-11. The lower part of the airtight container 1-8 is connected with the collecting vessel 1-14, and the organic coolant 1-15 is housed in the collecting vessel 1-14, which is used to cool the sprayed liquid droplets into solid particles 1-13. The function of adjusting the distance between the liquid surface of the coolant 1-15 and the nozzle 1-11 is realized by connecting differe...

Embodiment 3

[0043] This embodiment takes liquid sodium as an example to illustrate the specific process of measuring the atomized particle size distribution and overall atomization rate of liquid sodium using the method proposed in the present invention.

[0044] 1. Preparatory work: Due to the active chemical properties of liquid sodium, it is necessary to ensure the inert gas environment in the experimental container before the spray test to prevent oxidative combustion of liquid sodium during the spraying process. Heat the sodium in sealed crucibles 1-6 to 300°C and select the nozzle. Set a collection dish 1-4 filled with liquid paraffin 1-3 at the bottom of the experimental container, adjust the height so that the liquid level of the paraffin remains at a position 2m away from the nozzle, and the temperature of the liquid paraffin is room temperature.

[0045] 2. Spray experiment and droplet solidification: The liquid sodium is injected from the nozzle with 2 atmospheres of argon, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com