Refining furnace oxygen burning gun with anti-temper and anti-explosion functions and application method thereof

An explosion-proof and oxygen-burning gun technology, which is applied in the field of iron and steel metallurgy, can solve the problems of increasing the amount of scrap steel loaded, no substantive solutions for anti-tempering and anti-burning, and tempering and explosion, so as to improve the preheating efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

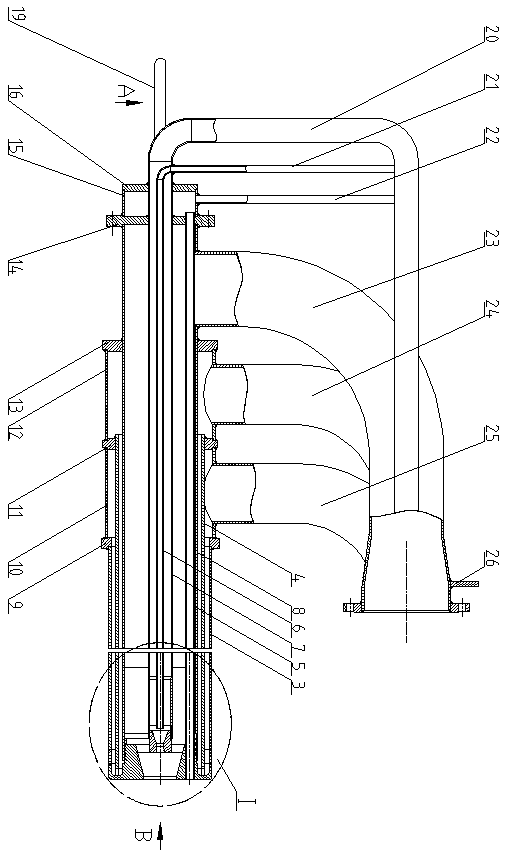

[0039] Example 1 A high-efficiency refining furnace oxygen burner with anti-tempering and anti-combustion functions

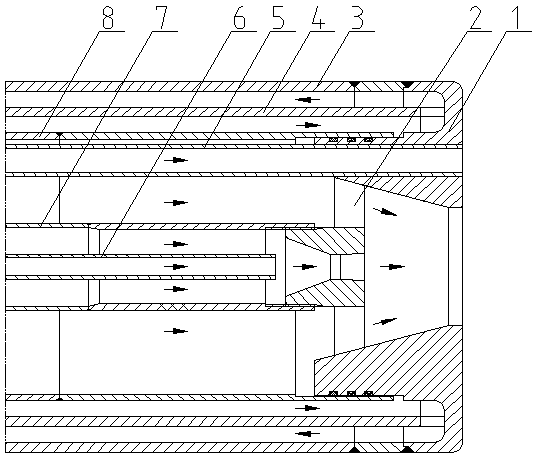

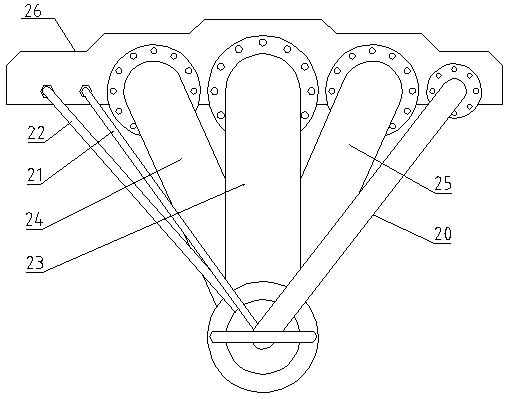

[0040] Such as figure 1 with figure 2 Commonly shown, the present invention provides a kind of high-efficiency refining furnace oxygen combustion gun with anti-tempering and anti-combustion function. Composed of five-layer casings, the centerlines of the five-layer casings are collinear, and the five-layer casings are compressed air pipes 6, oxygen pipes 7, converter gas pipes 8, water pipes 4 and outer pipes 3 from the inside to the outside. The pipes are reinforced with an appropriate number of evenly arranged ribs; the sandwich chamber between the oxygen pipe 7 and the converter gas pipe 8 is provided with three permanent flame pipes 5 distributed in an equilateral triangle.

[0041] Such as figure 2 , Figure 5 with Image 6Commonly shown, the nozzle includes a cooling nozzle 1 and a gas nozzle 2, the cooling nozzle 1 is fixed on the end of the outer...

Embodiment 2

[0048] Embodiment 2 A method of using a high-efficiency refining furnace oxygen burner with anti-tempering and anti-explosion functions

[0049] When the oxygen burner is used in an 80T refining furnace, the specific use process is as follows:

[0050] Step 1, preparation work, the permanent flame tube 5 in the oxygen burner is in a continuous lighting state; the compressed air tube 6 is in a continuous jetting state, and the compressed air passes through the end of the compressed air tube 6 and passes through the gas nozzle 2 and the cooling nozzle in turn 1 after spraying;

[0051] Step 2: Open the water inlet and outlet valves of the cooling water, the flow rate is 280t / h, the cooling water with a cooling water pressure ≥ 1.2Mpa flows from the water inlet elbow 24 through the water inlet connection 12, and then enters the inner cavity of the water pipe 4, the inner cavity The middle cooling water flows back after passing through the cooling nozzle 1, and the water is disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com