Guide hydraulic control system with oil changing function

A technology of hydraulic control system and pilot control valve, which is applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of difficult preheating of hydraulic oil, achieve the goal of improving preheating efficiency and shortening preheating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

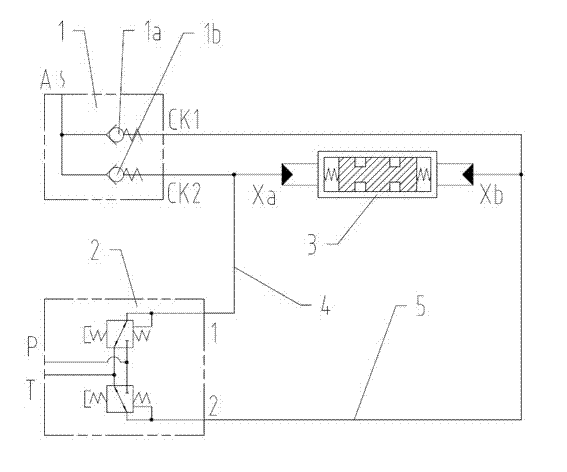

[0018] figure 1 A schematic diagram of the pilot hydraulic control system of the present invention is shown. Such as figure 1 As shown, port 1 of the pilot control valve 2 is connected to the Xa oil chamber of the reversing valve 3 through the left pipeline 4, and port 2 of the pilot control valve 2 is connected to the Xb oil chamber of the reversing valve 3 through the right pipeline 5. The oil circuit includes a one-way valve group 1 and an oil change inlet A. The one-way valve group 1 includes two one-way valves 1a and 1b. The oil outlet CK2 of one check valve 1a in the check valve group communicates with the left pipeline 4, and the oil outlet CK1 of the other check valve 1b communicates with the right pipeline 5. In the pilot hydraulic control system of the present invention, when the engine is warmed up, the pilot control valve is in the neutral position, and the oil change inlet port of the oil change oil circuit introduces the preheated hydraulic oil into the left pi...

Embodiment 2

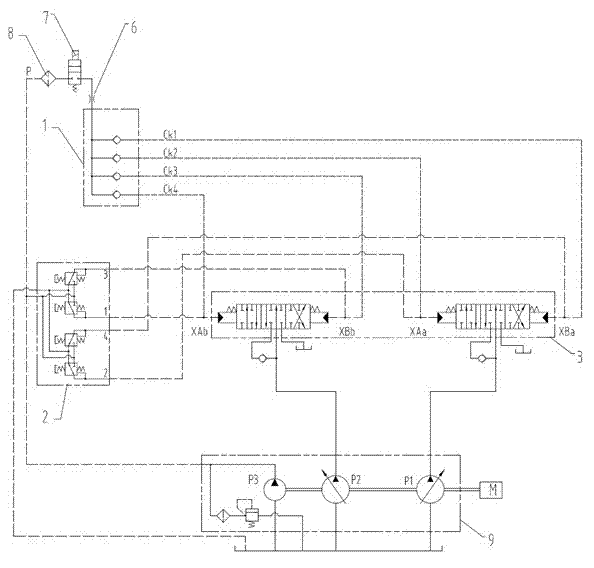

[0020] figure 2 Shows the application of the pilot hydraulic control system of the present invention on hydraulic excavators, such as figure 2 As shown, in the hydraulic excavator, for the sake of stability and safety, two sets of pilot hydraulic control systems in parallel are used. In the oil change circuit, the one-way valve group includes four one-way valves, which are respectively connected to two sets of pilot control systems. In the left and right pipelines, the oil inlets of the check valves in the one-way valve group are connected to each other, and then the restrictor 6, the solenoid valve 7 and the rear filter 8 are connected in series, and the oil change inlet P passes through the pipeline and the pump group The oil outlet pipeline of the pilot pump P3 in No. 9 is connected to obtain the preheated oil source.

Embodiment 3

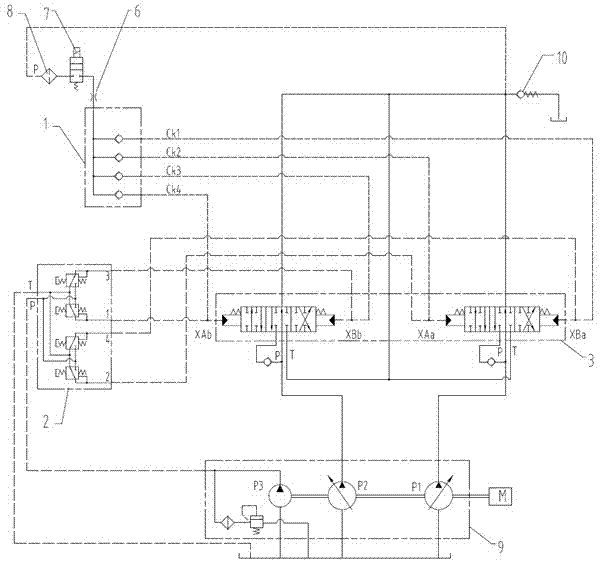

[0022] image 3 Another application of the pilot hydraulic control system of the present invention on hydraulic excavators is shown, such as image 3 As shown, the difference from Embodiment 2 is that the oil change inlet P communicates with the main oil return before the oil return back pressure valve 10 to obtain a preheated oil source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com