Lactobacillus paracasei producing bacteriocin and application thereof

A technology for producing bacteriocin and paracheese, applied in the directions of lactobacillus, application, bacteria, etc., can solve the problems of complicated operation, low safety of expression product activity, low yield of lactic acid bacteria bacteriocin on a large scale, etc., and achieves a wide application prospect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

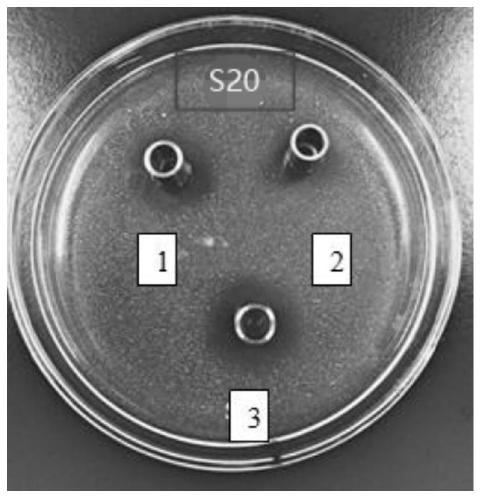

[0035] Implementation Example 1 Screening and identification of bacteriocin-producing lactic acid bacteria

[0036] (1) Strain activation

[0037] (a) Activation of bacteriocin-producing lactic acid bacteria: samples of traditional fermented foods collected from various places in the early stage, such as homemade yogurt, milk tofu, kimchi, milk bumps, milk fans, sweet fermented grains, etc., were isolated from more than 100 strains using MRS and M17 medium Lactic acid bacteria strains were purified by streaking, and the freeze-dried tubes were stored in the refrigerator.

[0038]Streak the lactic acid bacteria strain on the MRS plate (purchased from Haibo Biology), place it in 37°C for anaerobic culture for 48 hours, pick a single colony on the plate, and then transfer it to MRS liquid medium for activation at 37°C for 24 hours, repeat the activation step 2 times, and set aside.

[0039] (b) Activation of indicator bacteria: with Escherichia coli (E.coli) and Staphylococcus a...

Embodiment 2

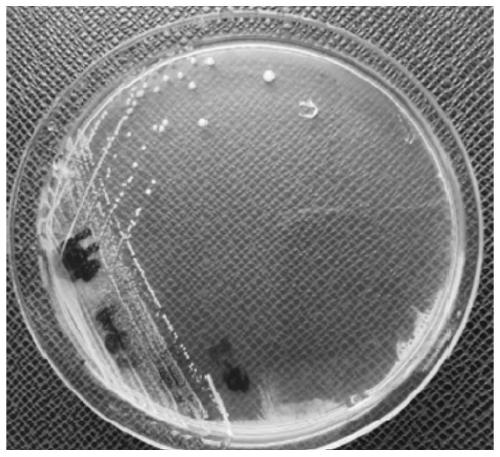

[0058] Implementation Example 2 The preparation of the crude extract of bacteriocin produced by bacterial strain S20

[0059] 1) Determination of salting-out saturation by fractional precipitation

[0060] Lactobacillus paracasei S20 was inoculated in MRS liquid medium, placed at 37°C for static culture for 28-48 hours to obtain a fermentation liquid, and centrifuged at 4°C and 8000r / min for 10 minutes to obtain a fermentation supernatant.

[0061] The crude extract of bacteriocin was prepared by fractional precipitation with ammonium sulfate. First determine the salting-out saturation of the graded precipitation, grind the ammonium sulfate into powder, slowly stir and add it to the fermentation supernatant, when it appears turbid and does not clarify for 2 minutes, calculate the salting-out saturation at this time according to the salting-out table, and store it in a 4°C refrigerator Stand overnight, centrifuge (4°C, 8000r / min, 20min), and collect supernatant and precipitate...

Embodiment 3

[0072] Determination of the properties of the crude extract of bacteriocins produced by implementation example 3 S20

[0073] (1) Determination of protein content in crude extract

[0074] Adopt Coomassie Brilliant Blue method to measure the protein content of the bacteriocin crude extract prepared in Example 2, the bovine serum albumin solution with a concentration of 1mg / mL is used as the standard protein solution, the standard protein content is the abscissa, and the absorbance at 595nm Is the ordinate, draws the standard curve, obtains the linear regression equation to be y=1.021x+0.017 (R 2 = 0.999). After the crude extract was redissolved in water, the concentration of 2.5mg / mL was prepared, and after appropriate dilution, the protein content was determined. It can be obtained by calculation that the protein content in the crude bacteriocin is 2.12mg / 2.5mg, and the protein content reaches 85%, which shows that the crude bacteriocin is mainly a protein substance, and at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com