Segmented copolymer thermoplastic dielectric elastomer thin membrane and dielectric driver of thin membrane

A thermoplastic elastomer and block copolymer technology, which is applied in the field of block copolymer thermoplastic dielectric elastomer film and its dielectric driver, can solve problems such as difficult driving deformation, and achieve the effect of improving the breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

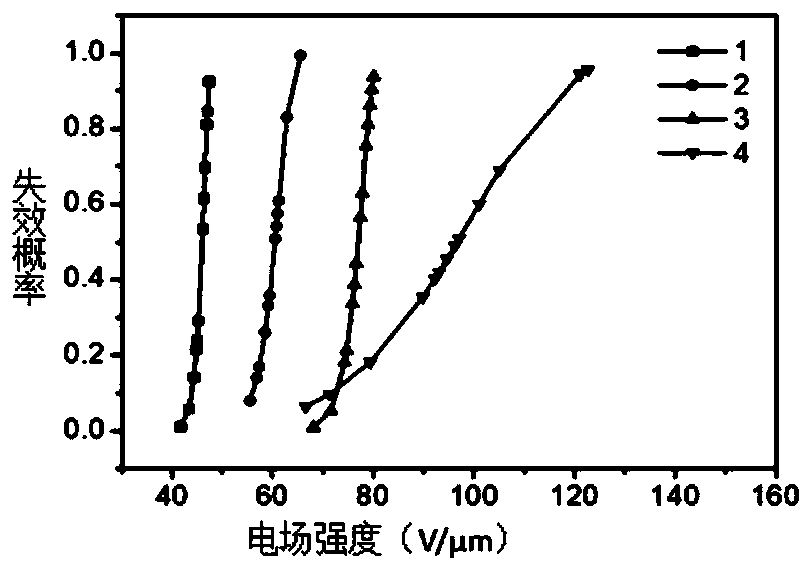

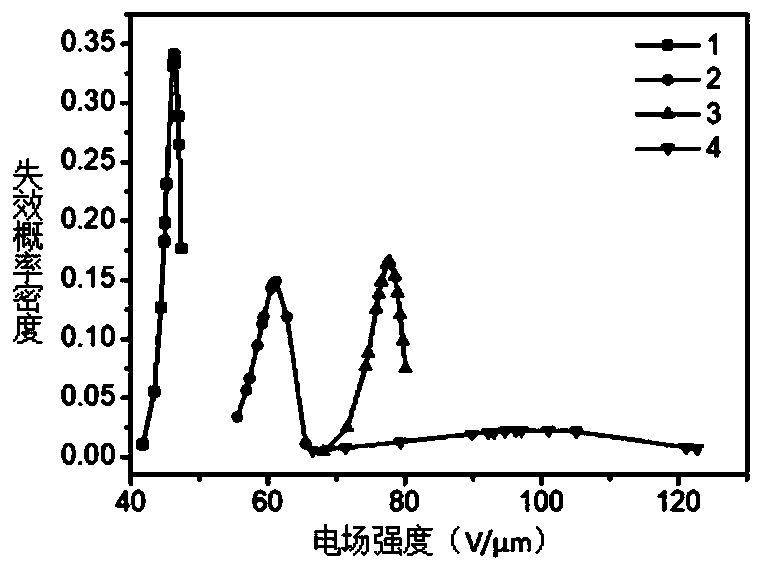

[0022] Example 1: Equivalent 4-axis pre-stretching and heat-relaxed dielectric elastomer based on polystyrene-poly(n-butyl acrylate)-polystyrene (molecular weight: 1.5W-12W-1.5W) triblock thermoplastic elastomer film Evaluation of Electrical Breakdown Field Strength of Thin Films

[0023] The initial film (thickness is about 83 microns) of polystyrene-polyacrylate n-butyl acrylate-polystyrene triblock thermoplastic elastomer is respectively pre-stretched to twice the area of the initial film (thickness is about 44 microns) Micron), 3 times (thickness is about 26 microns), about 7 times (thickness is about 12 microns); under fixed pre-stretching conditions, put it in 115 ° C for 10 hours and then cool at room temperature. The electrical breakdown field strength of the dielectric elastomer film was obtained by comparing the Weibull distribution before and after pre-stretching thermal relaxation. From figure 1 and figure 2 It can be seen that the greater the pre-stretching ...

Embodiment 2

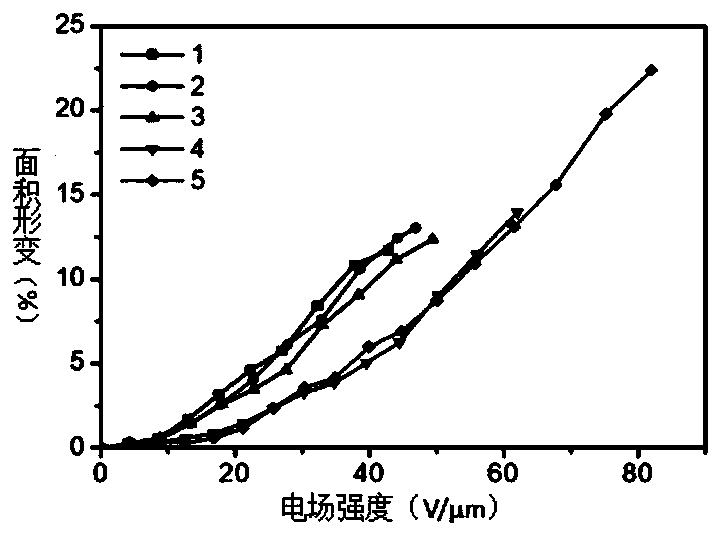

[0025] Example 2: Equivalent 4-axis pre-stretching and heat-relaxed dielectric elastomer based on polystyrene-poly(n-butyl acrylate)-polystyrene (molecular weight: 1.5W-12W-1.5W) triblock thermoplastic elastomer film Thin Film Driving Performance Test

[0026] The initial films of polystyrene-poly(n-butyl acrylate)-polystyrene triblock thermoplastic elastomer (with thicknesses of 200 microns, 100 microns, 50 microns, 25 microns, and 12 microns) were pre-stretched separately by equal 4-axis To a dielectric elastomer film with a thickness of 12 microns; under a fixed pre-stretching condition, put it in 115 ° C for 10 hours and then cool it at room temperature. Then the same carbon nanotube flexible electrodes were coated on the upper and lower surfaces of the dielectric elastomer film for electrical driving test. Such as image 3As shown, the electrical breakdown voltage of the initial film with a thickness of 12 microns is about 450V, the breakdown field strength is about 42....

Embodiment 3

[0028] Example 3: Based on polystyrene-polyacrylate n-butyl acrylate-polystyrene (molecular weight: 1.5W-12W-1.5W) three-block thermoplastic elastomer film after different degrees of uniaxial pre-stretching and thermal relaxation Anisotropy drives performance

[0029] The initial film of polystyrene-polyacrylate n-butyl acrylate-polystyrene triblock thermoplastic elastomer is pre-stretched to 2 times and 4 times the length of the initial film respectively through uniaxial; Cool at room temperature after thermal relaxation at 110°C for 10 hours. Then the same carbon nanotube flexible electrodes were coated on the upper and lower surfaces of the dielectric elastomer film for electrical driving test. Such as Figure 4 As shown, self-supporting frameless electric actuation produces anisotropic deformation, and the initial film without pre-stretching treatment (such as Figure 4 As shown in (a), there is no obvious anisotropic deformation when the voltage is applied; the dielect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com