A magnetic covalent triazine framework material and its preparation method and application

A covalent triazine framework, magnetic technology, applied in chemical instruments and methods, natural water treatment, physical/chemical process catalysts, etc., can solve the problem of difficult recovery of covalent triazine framework materials, and achieve complete reaction and convenient recovery. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

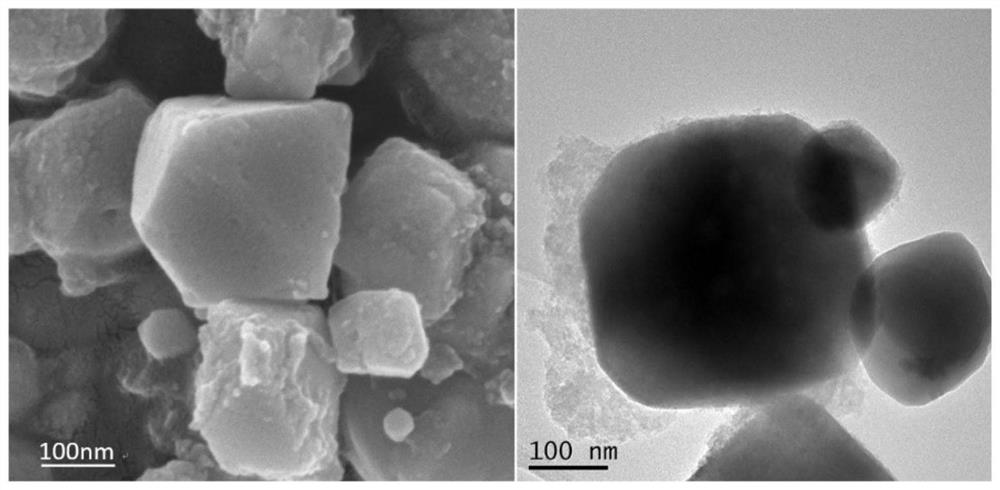

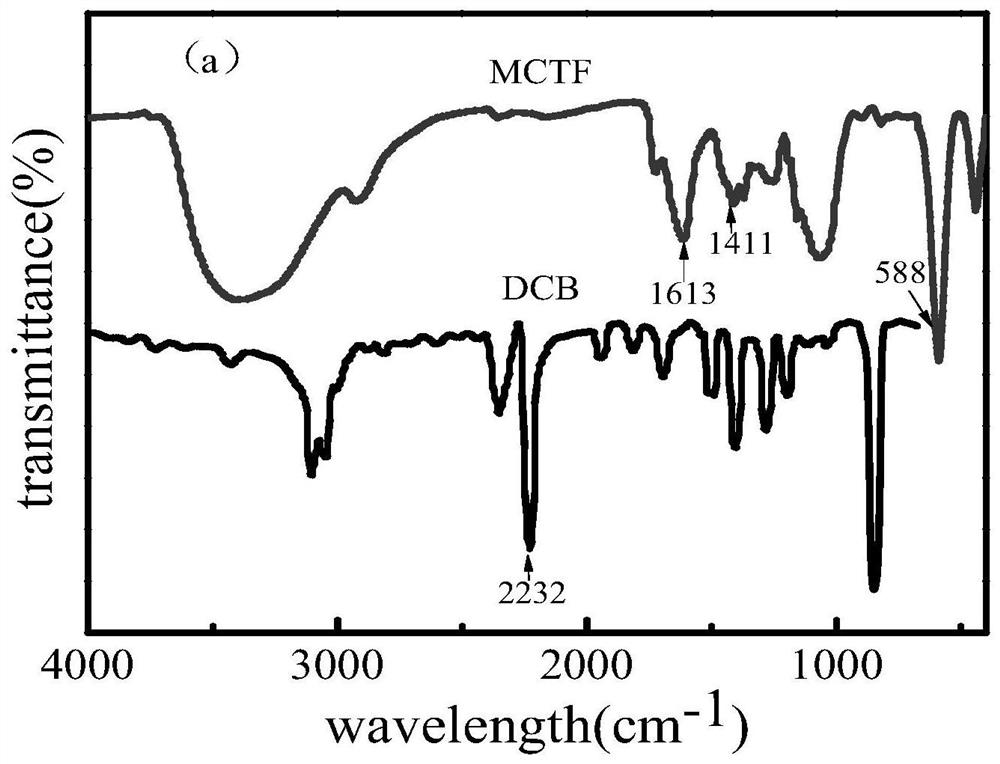

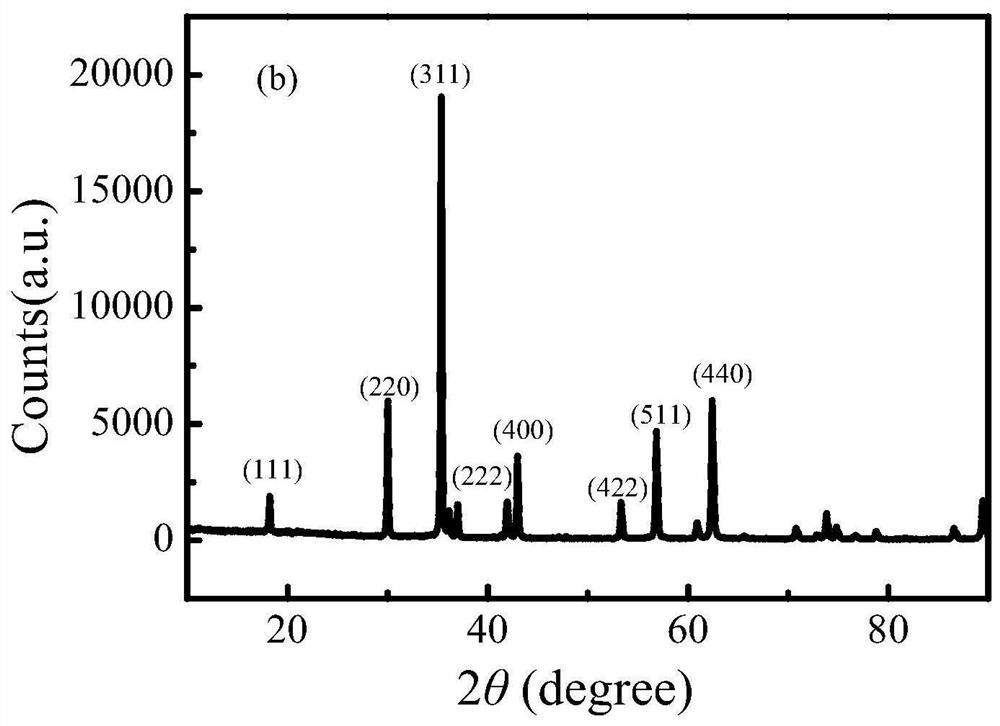

[0039] Weigh 2g terephthalonitrile and 2g Fe 3 o 4 , after mixing evenly, quickly add 16g ZnCl 2 , after mixing evenly, the powder was transferred into a quartz crucible, and reacted for 60 minutes under a power of 500W to obtain a black product, which was mixed with 0.1mol·L -1 HCl soak to remove residue while preventing ZnCl 2 After hydrolysis and soaking, the precipitate was separated under the condition of an external magnetic field, washed alternately with water and absolute ethanol three times, dried in vacuum at 60°C for 6 hours, taken out and ground to obtain 0.85g MCTF powder.

Embodiment 2

[0041] Weigh 2g terephthalonitrile and 4g Fe 3 o 4 , after mixing evenly, quickly add 16g ZnCl 2 , after mixing evenly, transfer the powder into a quartz crucible, and react at 300W for 60min to obtain a black product, which is mixed with 0.1mol·L -1 HCl soak to remove residue while preventing ZnCl 2 After hydrolysis and soaking, the precipitate was separated under the condition of an external magnetic field, washed alternately with water and absolute ethanol three times, dried in vacuum at 60°C for 6 hours, taken out, and ground to obtain 2.93g of MCTF powder.

Embodiment 3

[0043] Weigh 2g terephthalonitrile and 4g Fe 3 o 4 , after mixing evenly, quickly add 16g ZnCl 2 , after mixing evenly, transfer the powder into a quartz crucible, and react at 400W power for 60min to obtain a black product, which is mixed with 0.1mol·L -1 HCl soak to remove residue while preventing ZnCl 2 After hydrolysis and soaking, the precipitate was separated under the condition of an external magnetic field, washed alternately with water and absolute ethanol three times, dried in vacuum at 60°C for 6 hours, taken out and ground to obtain 2.68g of MCTF powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com