3D printing photocuring material and underwater curing after-treatment processing technology thereof

A light-curing material, 3D printing technology, applied in the field of printing, can solve the problems of poor stain resistance, rough outline, poor overall performance, etc., to improve the double bond conversion rate, reduce the degree of yellowing, and improve the overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

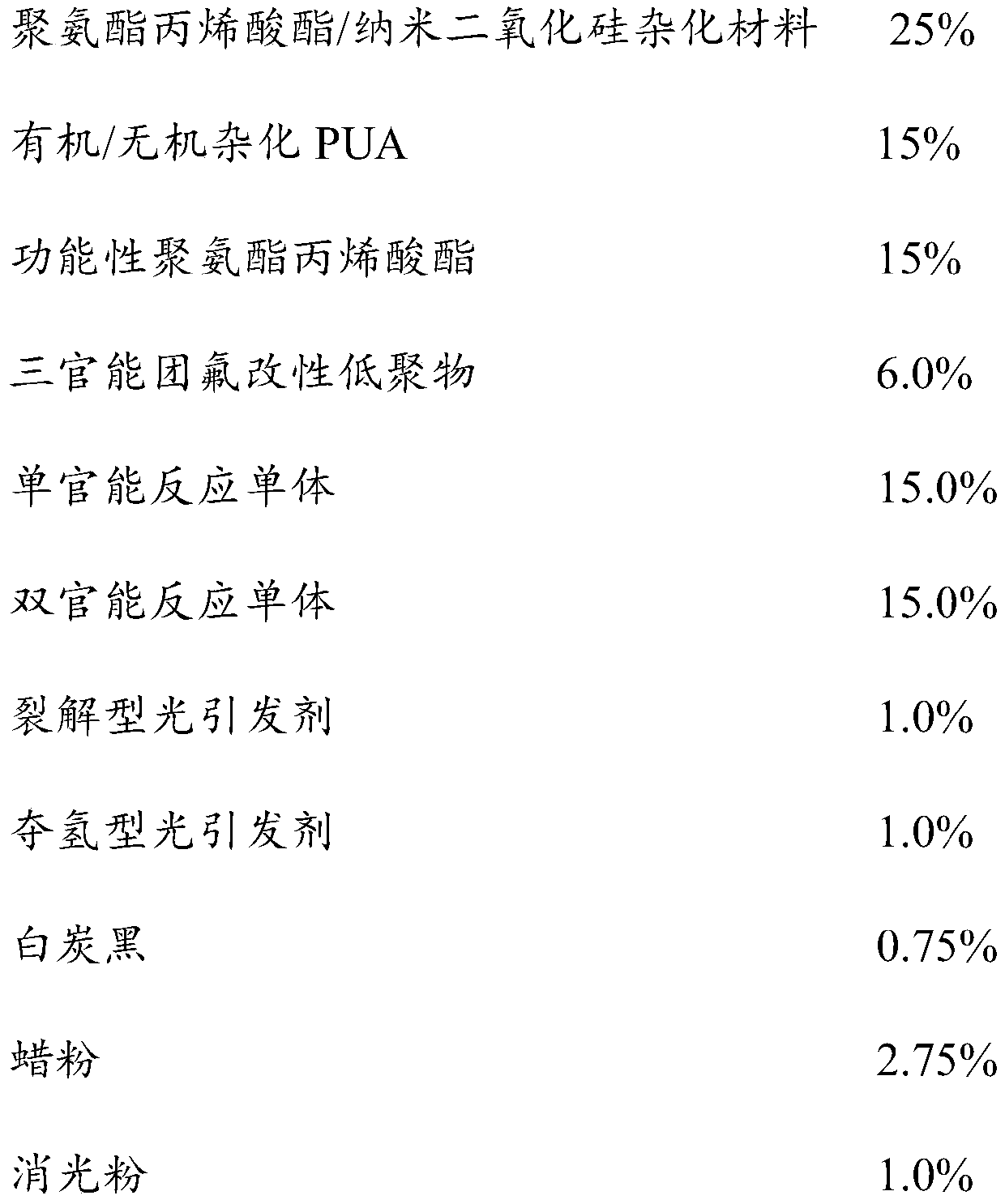

Embodiment 1

[0032]

[0033]

[0034] The above-mentioned mixture system is first cured and shaped by a 3D printing DLP device with UVA 385nm band, and then undergoes an underwater curing post-treatment process. Specifically, put the printed material workpiece into a sealed rotary LED-UV secondary underwater curing and ultrasonic thermal cleaning machine, and perform a sealed underwater secondary exposure and curing post-treatment on the same machine for a certain period of time. And ultrasonic heat cleaning treatment. Among them, the secondary curing light source is in the 355nm wave band, the internal box wall of the curing machine is a BMC material car lamp grade total reflection mirror, the lamp source current is 3A, the variable current control power is 300W, the curing time is 5min, the water used is deionized water, ultrasonic The power of the generator is 100W, the cleaning time is 9 minutes, and the heating temperature is 60 degrees.

Embodiment 2

[0036]

[0037]

[0038]The above-mentioned mixture system is first cured and shaped by a 3D printing DLP device with UVA 385nm band, and then undergoes an underwater curing post-treatment process. Specifically, put the printed material workpiece into a sealed rotary LED-UV secondary underwater curing and ultrasonic thermal cleaning machine, and perform a sealed underwater secondary exposure and curing post-treatment on the same machine for a certain period of time. And ultrasonic heat cleaning treatment. Among them, the secondary curing light source is 355nm wave band, the internal box wall of the curing machine is a BMC material car lamp grade total reflection mirror, the lamp source current is 1A, the variable current control power is 100W, the curing time is 10min, the water used is deionized water, ultrasonic The power of the generator is 300W, the cleaning time is 10 minutes, and the heating temperature is 60 degrees.

Embodiment 3

[0040]

[0041] The above-mentioned mixture system is first cured and formed by 3D printing DLP equipment in the ultraviolet UVA385nm band, and then the underwater curing post-treatment process is carried out. Specifically, put the printed material workpiece into a sealed rotary LED-UV secondary underwater curing and ultrasonic thermal cleaning machine, and perform a sealed underwater secondary exposure and curing post-treatment on the same machine for a certain period of time. And ultrasonic heat cleaning treatment. Among them, the secondary curing light source is in the 385nm band, the internal box wall of the curing machine is a BMC material car lamp grade total reflection mirror, the lamp source current is 4A, the variable current control power is 400W, the curing time is 3min, the water used is tap water, and the ultrasonic generator The power is 400W, the cleaning time is 8 minutes, and the heating temperature is 60 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com