An electroplating wastewater treatment system

A treatment system and technology for electroplating wastewater, applied in the fields of metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of secondary pollution, non-reusable adsorbents, waste of resources, etc., and achieve high-efficiency treatment , No secondary chemical pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

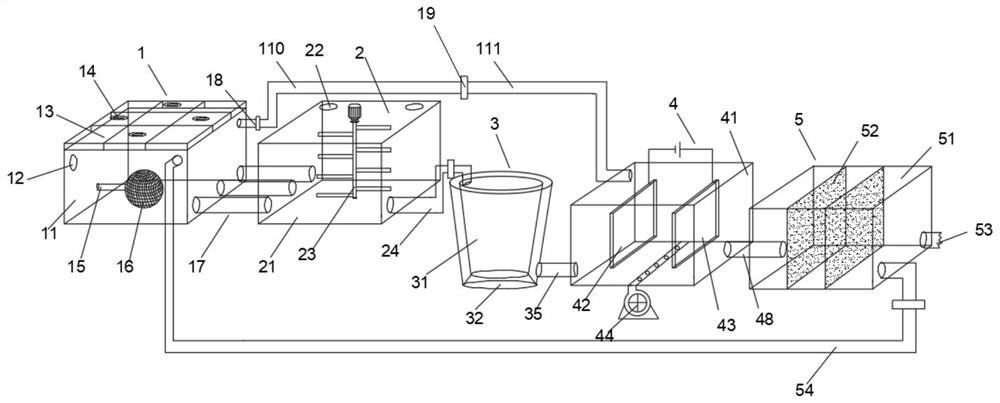

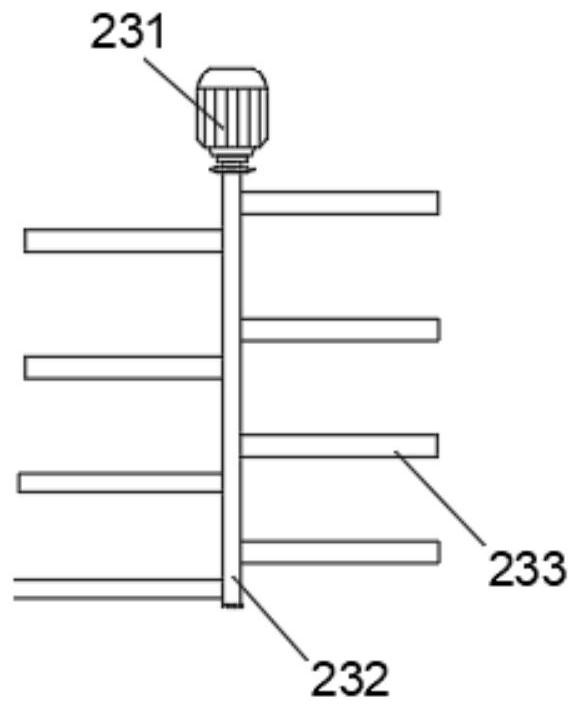

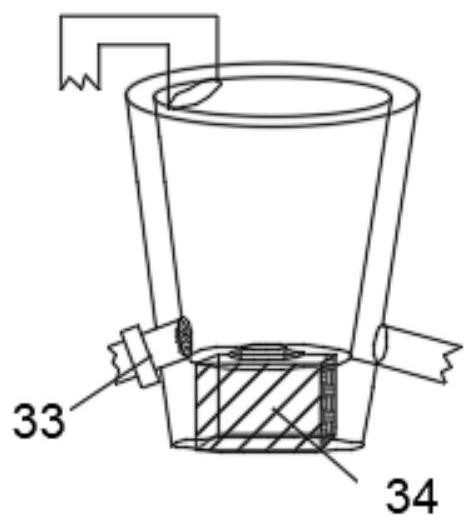

[0027] Example: as Figure 1-6As shown, an electroplating wastewater treatment system of the present invention includes a plant cultivation device 1, a primary treatment device 2, a centrifugal separation device 3, an electro-Fenton oxidation device 4 and an advanced treatment device 5. The plant cultivation device 1 consists of an incubator 11 , a chemical inlet 12, a carbon dioxide inlet pipe 15, a carbon dioxide aeration balloon 16, a concentrate delivery pipe 17, a valve 18, a power pump 19 and a first upper layer liquid delivery pipe 110. The incubator 11 is far from the side of the primary treatment device 2 A medicament inlet 12 is opened on the wall of the incubator 11, and a carbon dioxide inlet pipe 15 is fixedly connected to the box wall on the side of the incubator 11 close to the medicament inlet 12. The carbon dioxide inlet pipe 15 is arranged below the medicament inlet 12, and the carbon dioxide One end of the inlet pipe 15 extending to the inside of the incubat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com