Wound-managing and pain-settling plaster

A plaster and mucilage technology, which is applied in the field of medicine, can solve problems such as inaccessibility, and achieve the effects of safe use, promotion of transdermal absorption, and stable temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

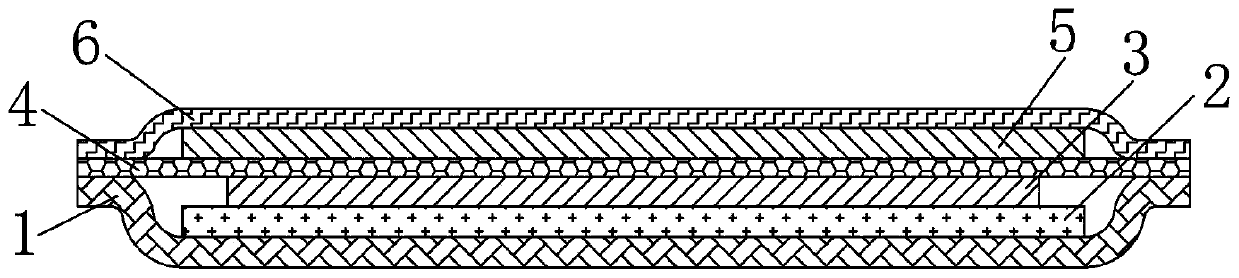

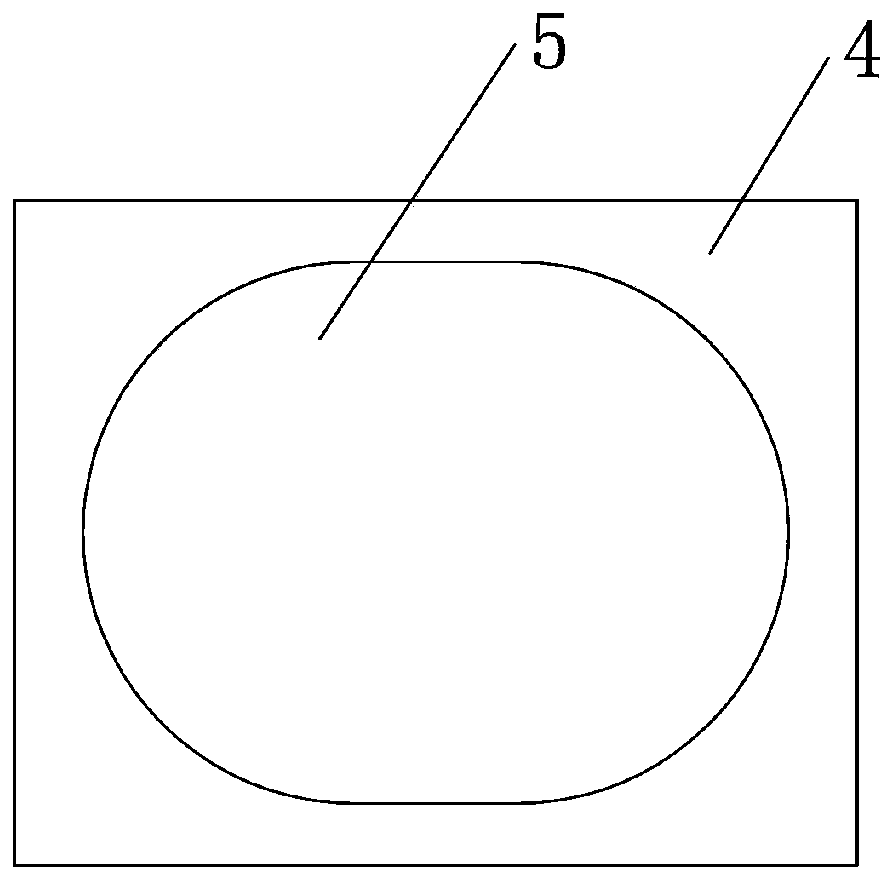

Image

Examples

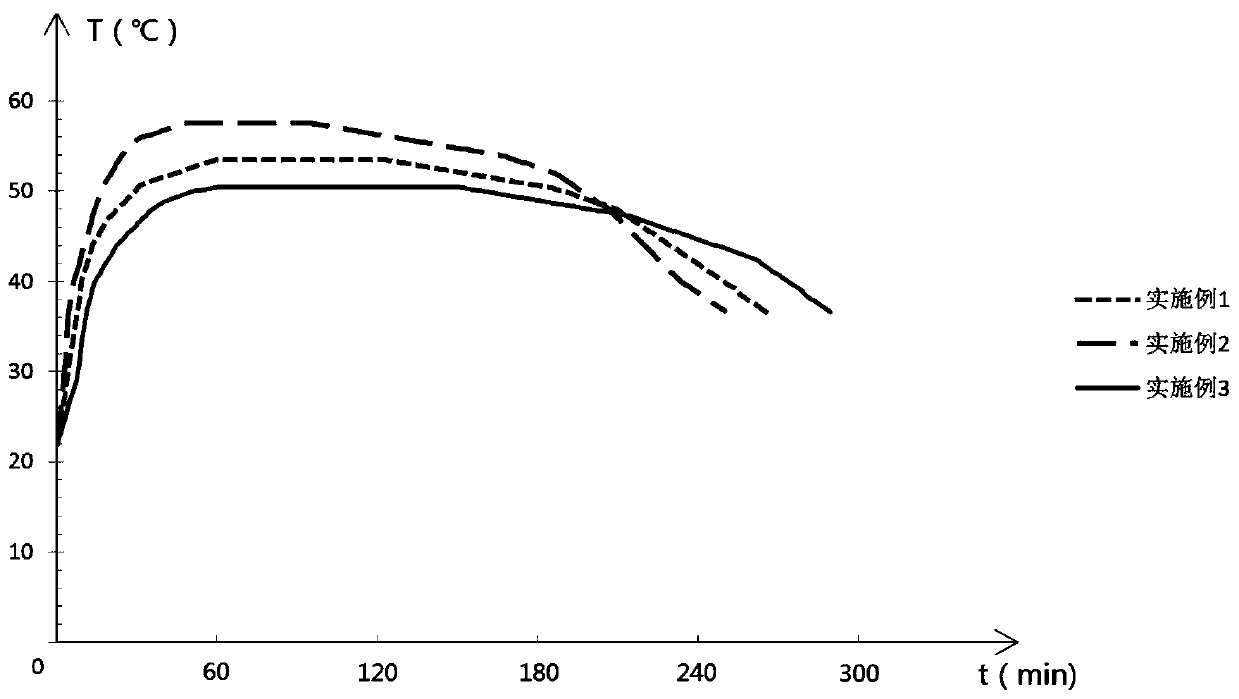

Embodiment 1

[0037] Example 1: Take 10g of star anise, wherein 2g of star anise is crushed into fine powder for later use, and the other 8g of star anise is crushed into coarse powder and placed in an extractor, add 4 times of its weight in purified water and soak for 1 hour, then extract by steam distillation 5h, collect star anise oil, set aside; take Clematis, stir-fried toosendan and chuanwu into coarse powder and put it in an extractor, add 4 times of its weight with 70% ethanol for heating and reflux extraction, reflux extraction The temperature is 75-85°C, and the time for reflux extraction is 3 hours. After the reflux extraction, the slag liquid is separated, filtered, and the filtrate is concentrated under reduced pressure to form a thick paste. The thick paste is dried at 60°C to form an extract, and the extract is broken into fine powder. Obtain 3.5g of extract powder and set aside; take a specified amount of sodium polyacrylate and disperse it in an appropriate amount of purifie...

Embodiment 2

[0039] Example 2: Take 10g of star anise, wherein 2.5g of star anise is crushed into fine powder for later use, and another 7.5g of star anise is crushed into coarse powder and placed in an extractor, add 3 times its weight in purified water and soak for 1 hour, steam Distill and extract for 4 hours, collect star anise oil, and set aside; take Clematis clematis, stir-fried Toosendan, and Aconitum sichuan into coarse powder and put it in an extractor, add 3 times of its weight with 70% ethanol for heating and reflux extraction, and reflux The extraction temperature is 75-85°C, and the reflux extraction time is 3 hours. After the reflux extraction, the slag is separated, filtered, and the filtrate is concentrated under reduced pressure to form a thick paste. The thick paste is dried at 60°C to form an extract, and the extract is broken into fine powder, to obtain 4.0g of extract powder, and set aside; take a specified amount of sodium polyacrylate and disperse it in an appropriat...

Embodiment 3

[0041] Example 3: Take 10g star anise, wherein 1.5g star anise is crushed into fine powder for later use, and another 8.5g star anise is crushed into coarse powder and placed in an extractor, add 4 times its weight in purified water and soak for 1 hour, steam Distill and extract for 5 hours, collect star anise oil and set aside; take Clematis clematis, stir-fried Toosendan and Aconitum sichuan into coarse powder and put it in an extractor, add 4 times of its weight with 70% ethanol for heating and reflux extraction, reflux The extraction temperature is 75-85°C, and the reflux extraction time is 3 hours. After the reflux extraction, the slag is separated, filtered, and the filtrate is concentrated under reduced pressure to form a thick paste. The thick paste is dried at 60°C to form an extract, and the extract is broken into fine powder, to obtain 3.0g of extract powder, and set aside; take a specified amount of sodium polyacrylate and disperse it in an appropriate amount of pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com