Three-dimensional (3D) printing tubular porous titanium alloy prosthesis for limb large-segment bone defect and preparation method of 3D printing tubular porous titanium alloy prosthesis

A 3D printing, titanium alloy technology, used in 3D printing, prosthesis, metal processing equipment, etc., can solve the problem of slow bone growth and growth speed, poor bone-metal interface integration, and high incidence of secondary fractures problem, to achieve the effect of high fit, good osseointegration effect, and reduced stress shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] 1) Preparation of 3D printed tubular porous titanium alloy prosthesis

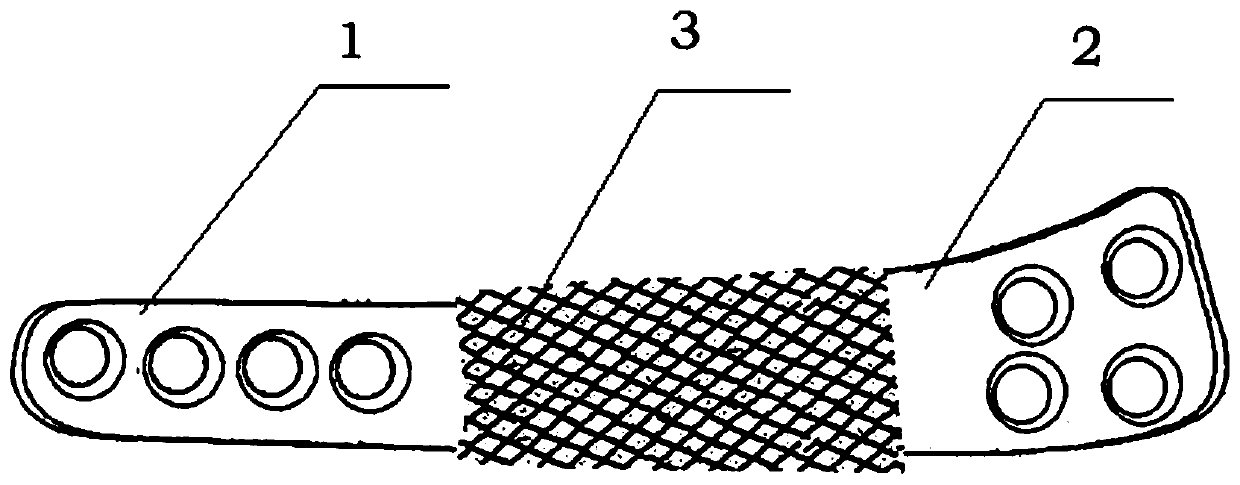

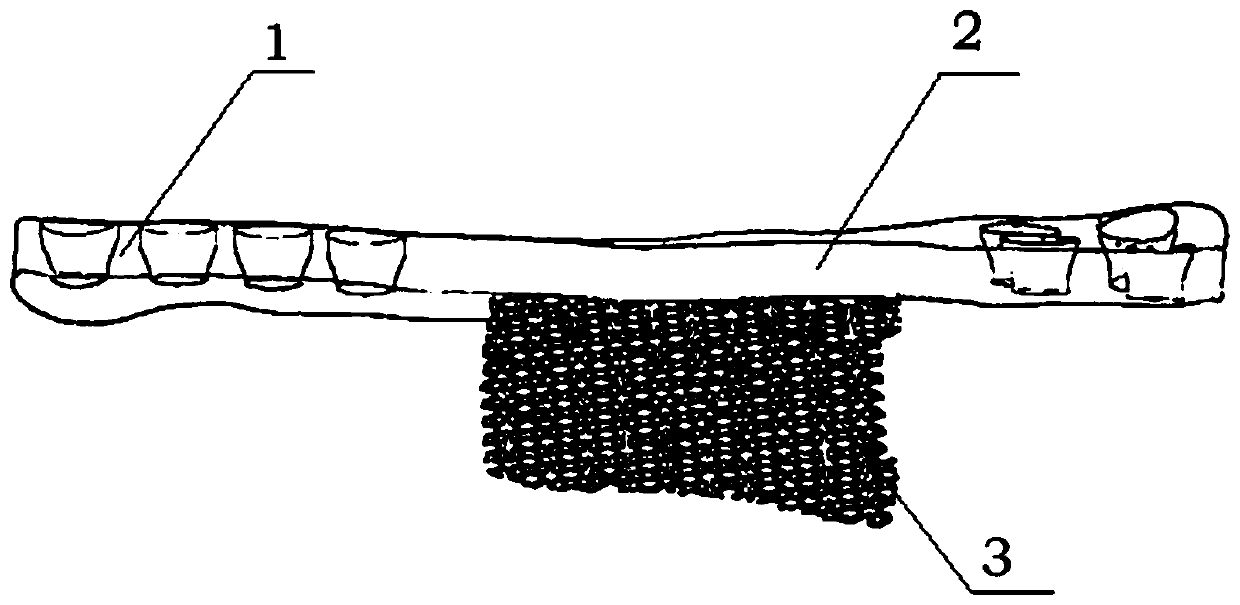

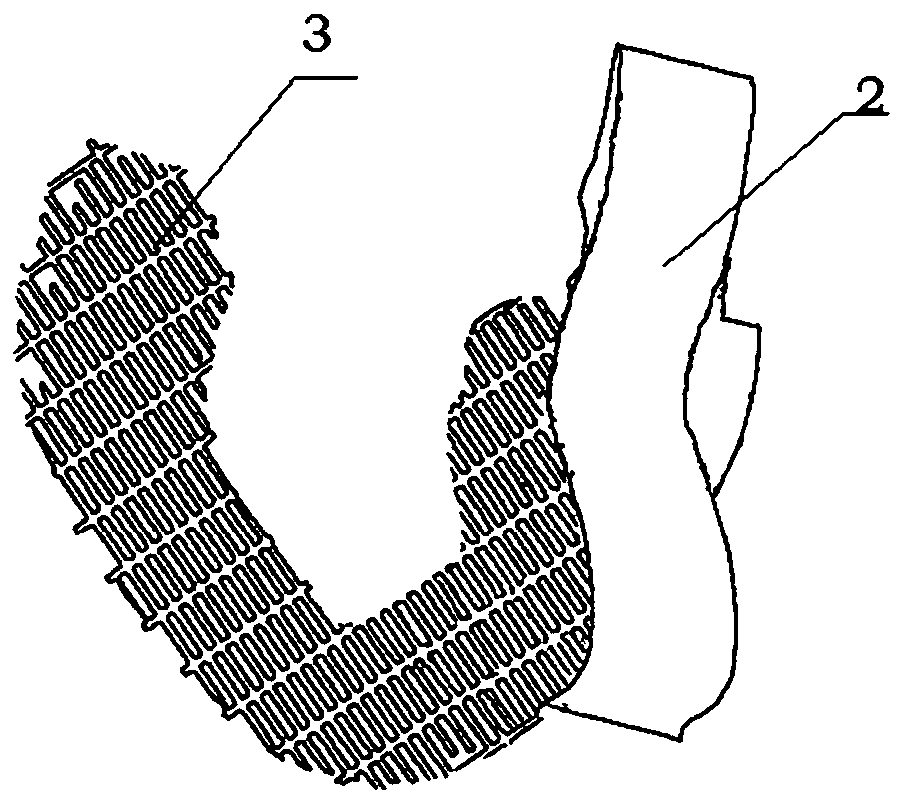

[0025] see figure 1 , 2. Using computer-aided design software, according to the patient's thin-section CT scan data, combined with the surgical path and the osteotomy plane shape of the lesion, design a hollow tubular porous prosthesis 2 with an osteosynthesis plate 1, see image 3 In order to facilitate fibula transplantation, the porous prosthesis 2 is designed as a hollow tubular bone grafting groove. The tube wall 3 has a porous structure, which is similar in shape to the backbone of the defect area. The thickness of the tube wall is 0.5mm-1.0mm greater than the backbone of the implanted area. Hexahedral diamond structure, its porosity is generally 50%-80%, and the pore diameter ranges from 500μm-700μm. There is a hollow bone graft groove on the tube wall, which is convenient ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com