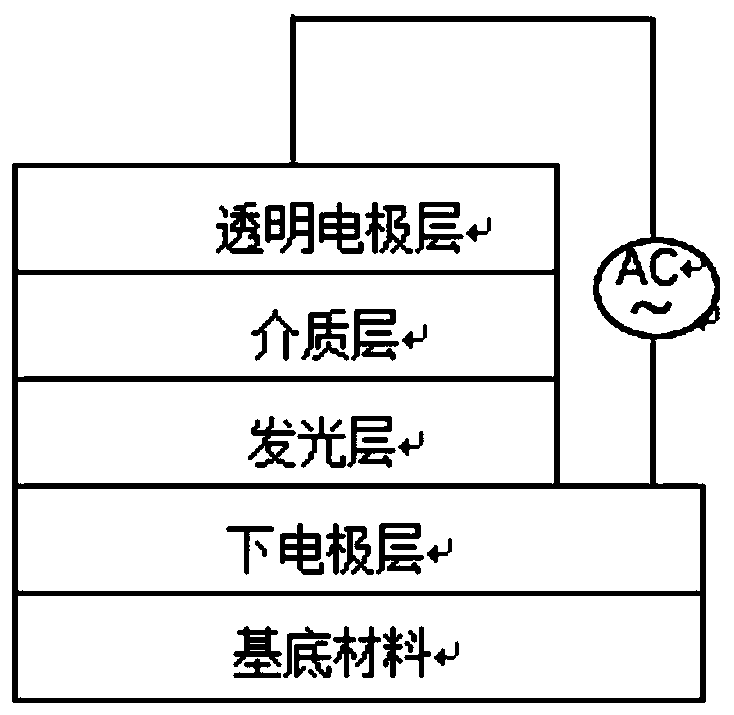

Method for manufacturing stereo inorganic electroluminescent device

An electroluminescent device and inorganic technology, applied in the field of making three-dimensional inorganic electroluminescent devices, can solve the problem of inability to prepare a continuous light-emitting film on a three-dimensional surface, and achieve the effects of good light-emitting effect, simple preparation process, and smooth and uniform functional layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

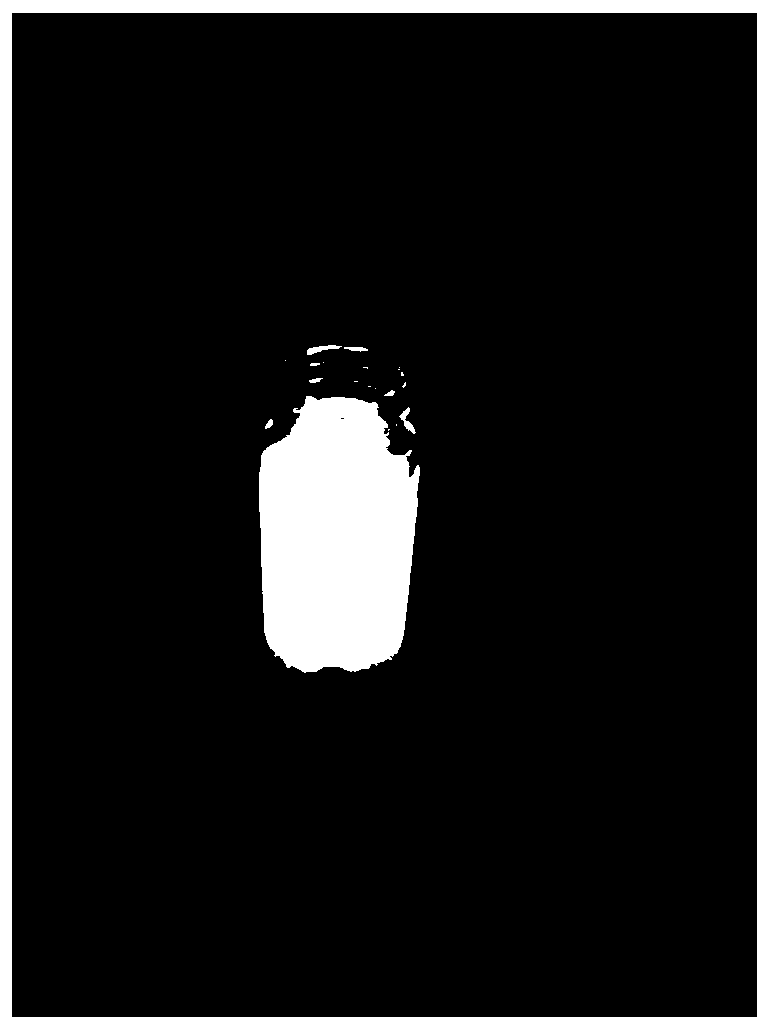

Embodiment 1

[0053] A method for making a three-dimensional inorganic electroluminescent device, comprising the steps of:

[0054] S1: Use a three-dimensional glass bottle as the base material, remove impurities on the inner and outer surfaces of the base material with alcohol, then pre-bake at 150°C for 30 minutes, and cool naturally for later use;

[0055] S2: Prepare the pastes used for the lower electrode layer, dielectric layer, light-emitting layer and transparent conductive layer respectively, as follows:

[0056] Preparation of lower electrode layer slurry: by mass percentage, add 47% ethyl acetate, 50% silver paste and 3% polyurethane resin into the container, and stir evenly;

[0057] Preparation of medium layer slurry: by mass percentage, add 10% BaTiO in the container 3 , 10% polyurethane resin and 80% ethyl acetate, stirred evenly;

[0058] Preparation of luminescent layer slurry: by mass percentage, add 20% ZnS:Mn, 10% ethyl cellulose resin, 69% DBE and 1% silicon dioxide i...

Embodiment 2

[0068] A method for making a three-dimensional inorganic electroluminescent device, comprising the steps of:

[0069] S1: Use PET film as the base material, remove impurities on the inner and outer surfaces of the base material with alcohol, then pre-bake at 130°C for 30 minutes, and cool naturally for later use;

[0070] S2: Prepare the pastes used for the lower electrode layer, dielectric layer, light-emitting layer and transparent conductive layer respectively, as follows:

[0071] Preparation of lower electrode layer slurry: by mass percentage, add 50% ethyl acetate, 40% silver paste and 10% polyurethane resin into the container, and stir evenly;

[0072] Preparation of medium layer slurry: by mass percentage, add 5% BaTiO in the container 3 , 20% polyurethane resin and 75% ethyl acetate, stirred evenly;

[0073] Preparation of luminous layer slurry: by mass percentage, add 30% ZnS:Mn, 5% ethyl cellulose resin, 62% DBE and 3% silicon dioxide into the container, and stir ...

Embodiment 3

[0082] A method for making a three-dimensional inorganic electroluminescent device, comprising the steps of:

[0083] S1: Use three-dimensional ceramics as the base material, remove impurities on the outer surface of the base material with alcohol, then pre-bake at 140°C for 30 minutes, and cool naturally for later use;

[0084] S2: Prepare the paste used for the lower electrode layer, dielectric layer, light-emitting layer and transparent conductive layer, as follows:

[0085] Preparation of lower electrode layer slurry: by mass percentage, add 55% DBE, 40% silver-copper paste and 5% polyurethane resin into the container, and stir evenly;

[0086] Preparation of medium layer slurry: by mass percentage, add 15% PbTiO in the container 3 , 20% acrylic resin and 65% ethyl acetate, stir evenly;

[0087] Preparation of luminescent layer slurry: by mass percentage, add 30% ZnS:Cu, 10% ethyl cellulose resin, 58% DBE and 2% silicon dioxide into the container, and stir evenly;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com