Ceramic fiber bundle knotting method

A technology of ceramic fibers and fiber bundles, which is used in jointing devices, textiles and papermaking, spinning machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for bonding ceramic fiber bundles, comprising the steps of:

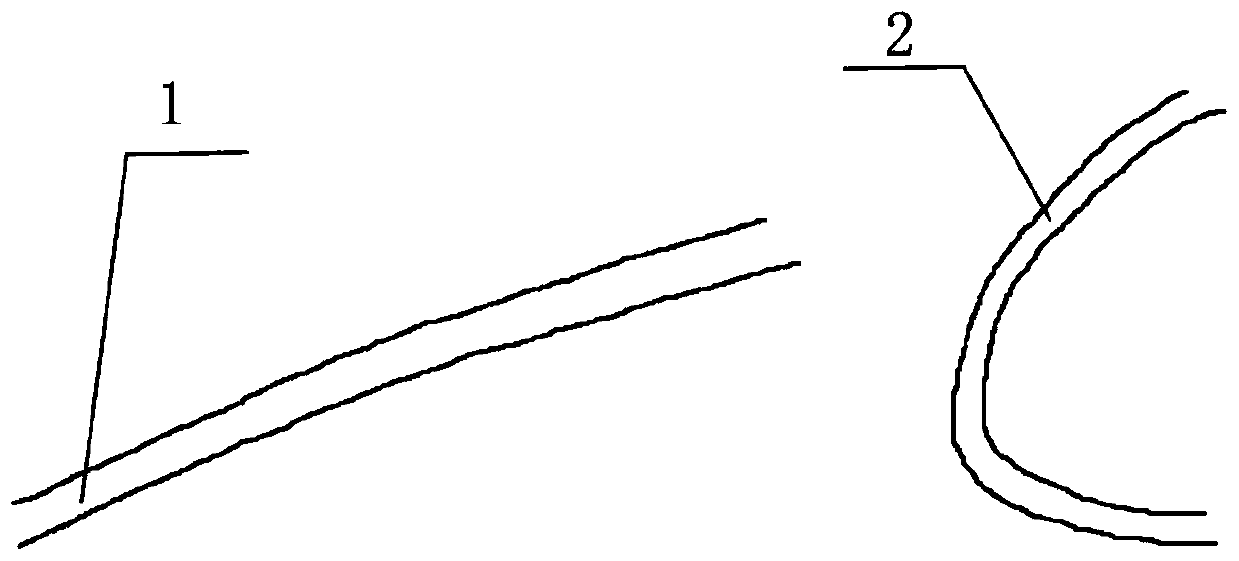

[0028] Step 1: Take the head end 1 of the boron carbide ceramic fiber bundle and the 10cm connecting yarn 2;

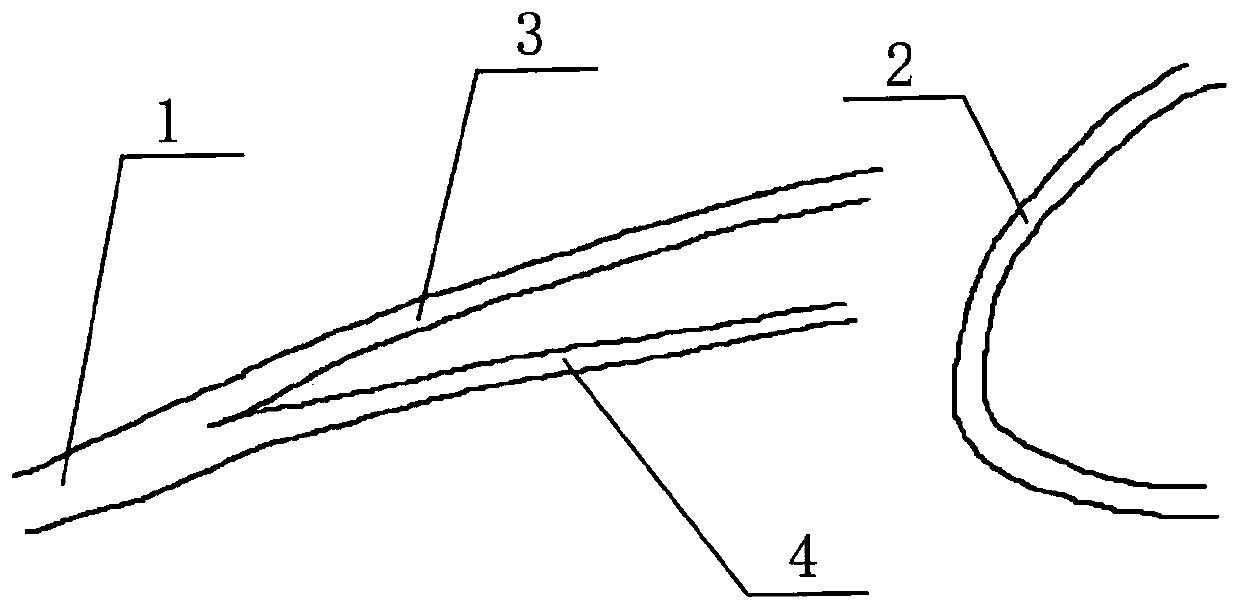

[0029] Step 2: dividing the boron carbide ceramic fiber bundle into A strand 3 and B strand 4 along the length direction;

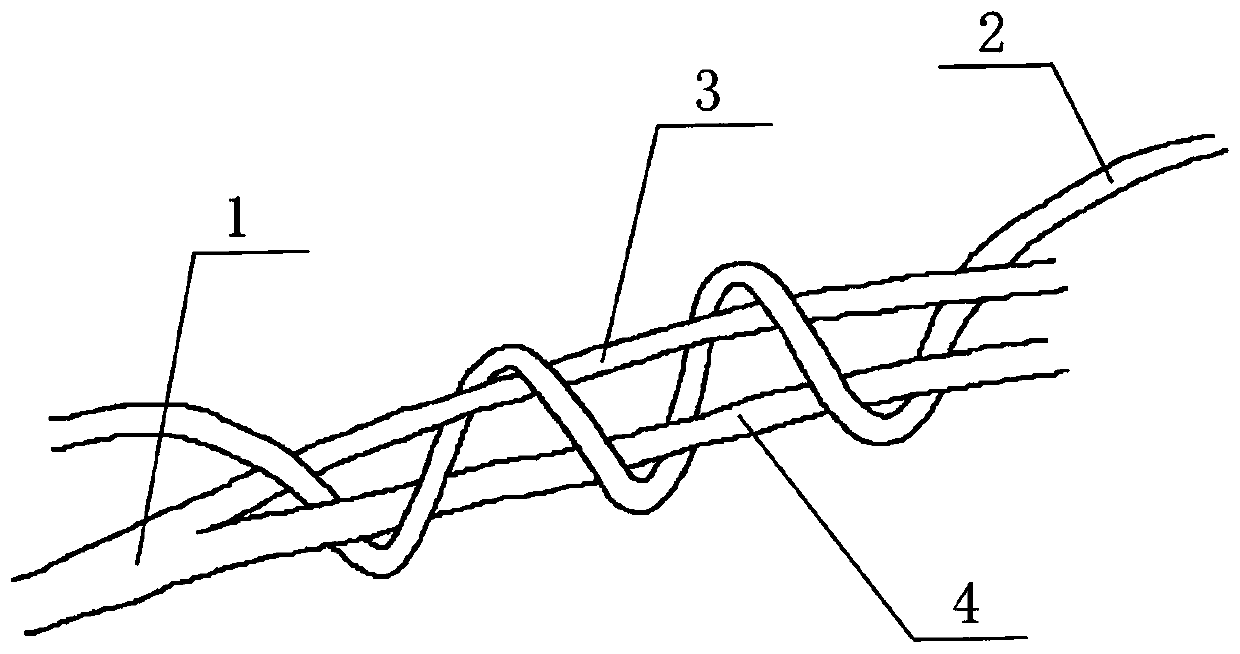

[0030] Step 3: thread one end of the aramid connecting yarn into the A strand 3 and the B strand 4 of the boron carbide ceramic fiber bundle, and wind 3 turns along the direction of the head end 1 of the boron carbide ceramic fiber bundle; The yarn at one end is wound 2 times in the opposite direction of the head end 1 of the boron carbide ceramic fiber bundle, leaving 2 cm in the middle to form a ring structure;

[0031] Step 4: Take a 2cm tape, and wrap the fiber bundles wound by the aramid connecting yarn in parallel and tightly in a clockwise direction.

[0032] Step 5: Thread the head end 5 of the spandex elastic tension yarn into the ring structure of the aramid...

Embodiment 2

[0035] A method for bonding ceramic fiber bundles, comprising the steps of:

[0036] Step 1: Take the head end 1 of the silicon carbide ceramic fiber bundle and the 12.5cm connecting yarn 2;

[0037] Step 2: divide the silicon carbide ceramic fiber bundle into A strand 3 and B strand 4 along the length direction;

[0038] Step 3: Thread one end of the nylon 6 connecting yarn into the A-strand 3 and B-strand 4 of the silicon carbide ceramic fiber bundle, and wind it 5 times along the direction of the head end 1 of the silicon carbide ceramic fiber bundle; the nylon 6 connecting yarn is another The yarn at one end is wound 2 times in the opposite direction of the head end 1 of the silicon carbide ceramic fiber bundle, leaving 2.5cm in the middle to form a ring structure;

[0039] Step 4: Take a 2.5cm tape, and wrap the fiber bundles wound in parallel with the nylon 6 connecting yarns in a clockwise direction and tightly wrap them.

[0040] Step 5: Thread the head end 5 of the ...

Embodiment 3

[0043] A method for bonding ceramic fiber bundles, comprising the steps of:

[0044] Step 1: Take the head end 1 of the alumina ceramic fiber bundle and the 15cm connecting yarn 2;

[0045] Step 2: dividing the alumina ceramic fiber bundle into A strand 3 and B strand 4 along the length direction;

[0046] Step 3: thread one end of the nylon 66 connecting yarn into the A-strand 3 and B-strand 4 of the alumina ceramic fiber bundle, and wind 4 turns along the direction of the head end 1 of the alumina ceramic fiber bundle; the nylon 66 connecting yarn is another The yarn at one end is wound around the head end 1 of the alumina ceramic fiber bundle in the opposite direction, leaving 3 cm in the middle to form a ring structure;

[0047] Step 4: Take a 2.5cm tape, and wrap the fiber bundles wound in parallel with the nylon 66 connecting yarns in a clockwise direction and tightly wrap them.

[0048] Step 5: Thread the head end 5 of the spandex elastic tension yarn into the ring st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com