Preparation method and application of lanthanum-loaded magnetic hydrothermal biochar adsorbent

A magnetic water and thermal biological technology, applied in the direction of water pollutants, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of difficult recovery of adsorbents, achieve good application prospects, improve dispersibility and load capacity, The effect of a good environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

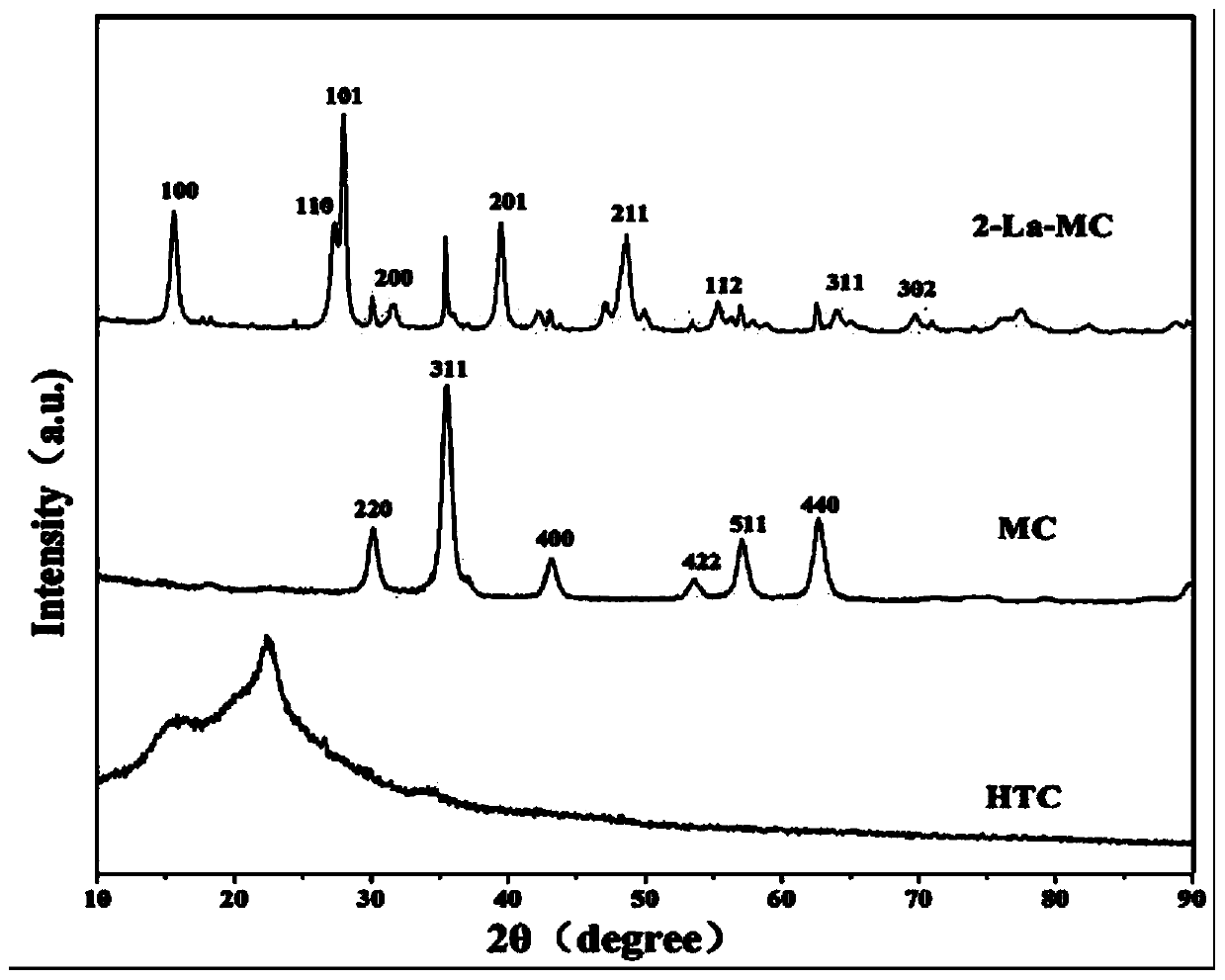

[0031] Weigh 20g of straw powder in 120ml of deionized water, fully stir and transfer to the reactor, react at 220°C and 4.5MPa for 2h, wash and dry at 105°C. The dried sample was ground and passed through an 80 mesh (0.178mm) sieve, washed several times with 1mol / L HCl solution, then washed with deionized water to neutrality, and dried in an oven at 80°C to obtain hydrothermal carbon HTC .

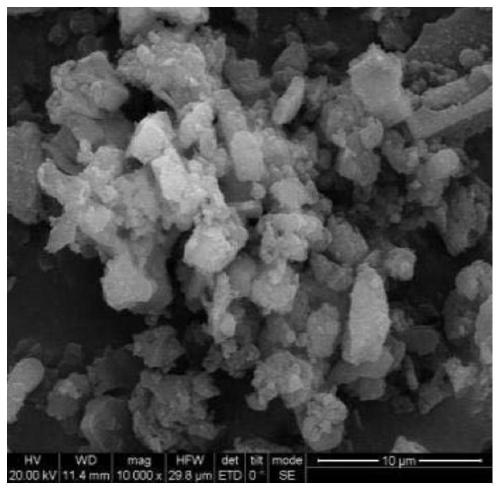

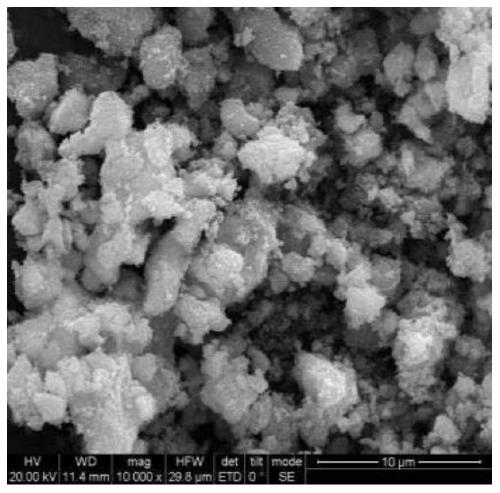

[0032] Put 200ml of deionized water in a three-necked flask, blow nitrogen gas for 30min at room temperature to exhaust the air in the flask, weigh 2.883g FeCl 3 ·6H 2 O and 1.060g FeCl 2 ·4H 2 O is dissolved in it, and then the different masses of LaCl are weighed 3 ·7H 2 O (Adjust FeCl 3 ·6H 2 O, FeCl 2 ·4H 2 O, LaCl 3 ·7H 2 The molar ratio of O (2:1:0, 2:1:2, 2:1:4 and 2:1:6) is placed in the flask. After dissolving completely, add 0.25g HTC, stir well, add concentrated ammonia water to pH 11, stir for 1h, warm to 80℃ for 1h, transfer to the reactor, react at 180℃ for 10h, use deionized w...

Embodiment 2

[0040] In this example, the adsorption process of phosphate radicals by an improved hydrothermal biochar phosphorus removal adsorbent made by the present invention was investigated. The preparation method of the phosphorus removal adsorbent in this embodiment is the same as the preparation method 1 described above. The adsorbent dosage is 0.2g / L, the initial phosphate concentration is 4mg P / L, the pH is adjusted to 7, the temperature is 25℃, and it is placed in a constant temperature oscillator to oscillate at a speed of 200r / min. The phosphate test method is molybdenum antimony Anti-colorimetric method. The quasi-second-order kinetic model is used to fit the measured data, and the results are as follows Figure 5 Shown. It can be seen that the fitting correlation coefficient R of the quasi-second-order kinetic model for 2-La-MC 2 Higher (R 2 =0.984), indicating that the quasi-second-order kinetic model can better describe the adsorption process of phosphate on the lanthanum-l...

Embodiment 3

[0042] In this example, the adsorption process of phosphate radicals by an improved hydrothermal biochar phosphorus removal adsorbent made by the present invention was investigated. The preparation method of the phosphorus removal adsorbent in this embodiment is the same as the preparation method 1 described above. The adsorbent dosage is 0.1g / L, the initial phosphate concentration is 0.5-15mg P / L, the pH is adjusted to 7, the temperature is 25℃, and it is placed in a constant temperature oscillator and oscillated at a speed of 200r / min for 3h. The phosphate test method is the molybdenum antimony colorimetric method. The Langmuir isotherm adsorption equation is used to fit the measured data, and the results are as follows Image 6 Shown. It is not difficult to find that the adsorption of phosphate on the lanthanum-loaded magnetic hydrothermal biochar is more in line with the Langmuir isotherm adsorption equation (R 2 =0.99), and 2-La-MC exhibits ultra-high phosphorus adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com