Core-shell composite particles for anode materials of lithium ion batteries

A technology of lithium-ion batteries and composite particles, applied in lithium batteries, battery electrodes, negative electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

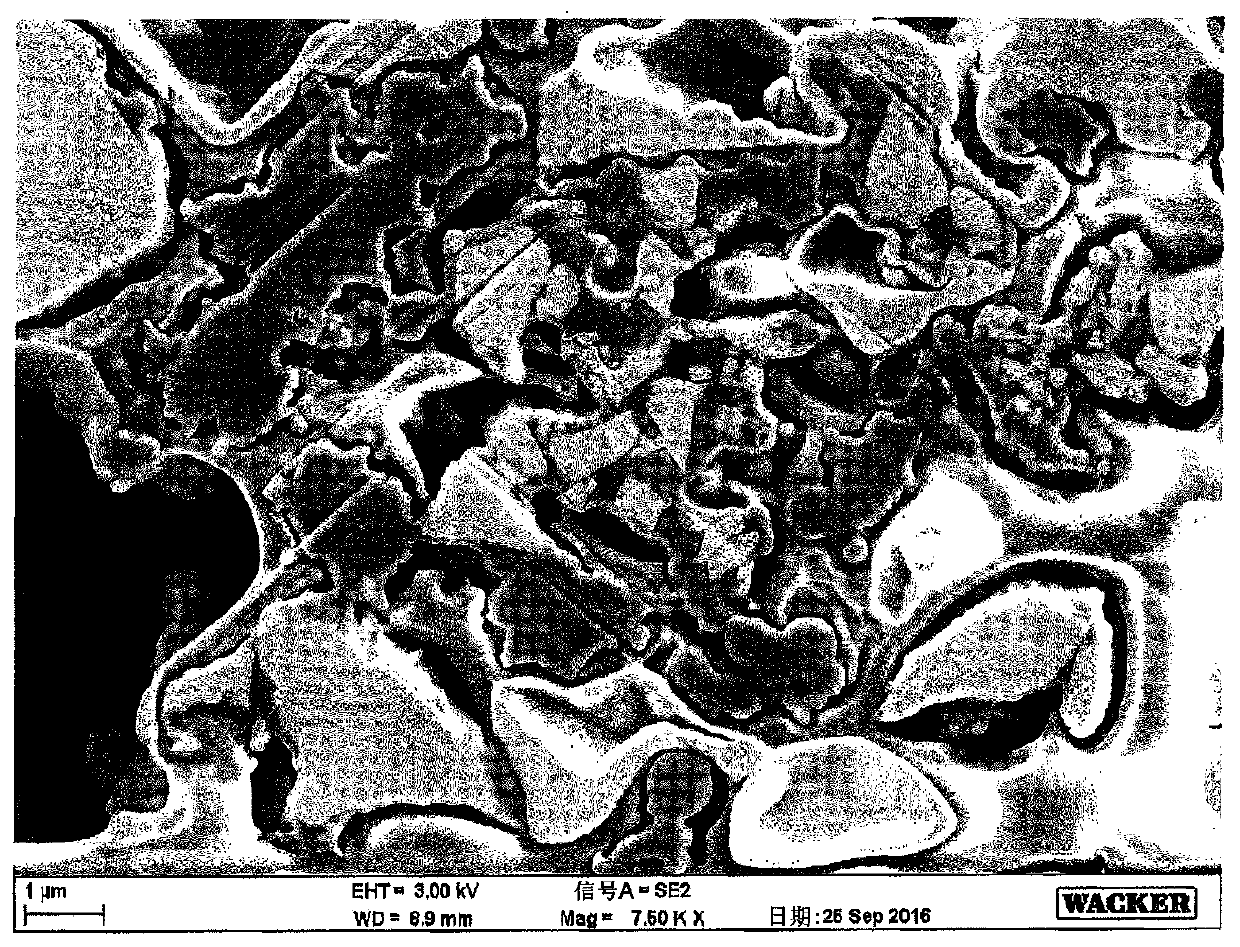

[0130] Core-shell composite particles (non-porous shell, core with global porosity, d of Si particles 50 =4.5μm):

[0131] a) Production of Sacrificial Material Pellets

[0132] 20.8 g melamine (Sigma-Aldrich #M2659) and 29.6 g formaldehyde (Sigma-Aldrich, 252549; 80.0 g 37% strength in water) were stirred at 50°C for 1 hour. Then 1200 ml of dilute nitric acid (pH 3.5) were added and the mixture was stirred at 100° C. for 50 minutes. After cooling, the supernatant was decanted and the solid was dried at 100°C for 15 hours. This gave 25.9 g of spherical melamine resin particles having a diameter D50 of 1-2 µm.

[0133] b) Coating of silicon particles and product from Example 1a with carbon precursor

[0134] Disperse 15g of silicon powder B by ultrasonic (Hielscher UIS250V; amplitude 80%, period: 0.75; duration: 30min) 50 = 4.5 μm) and 6.5 g of melamine resin particles from Example 1a, 8.2 g of resorcinol (Sigma-Aldrich, W358908) and 6.7 g of formaldehyde (18.1 g of a ...

Embodiment 2

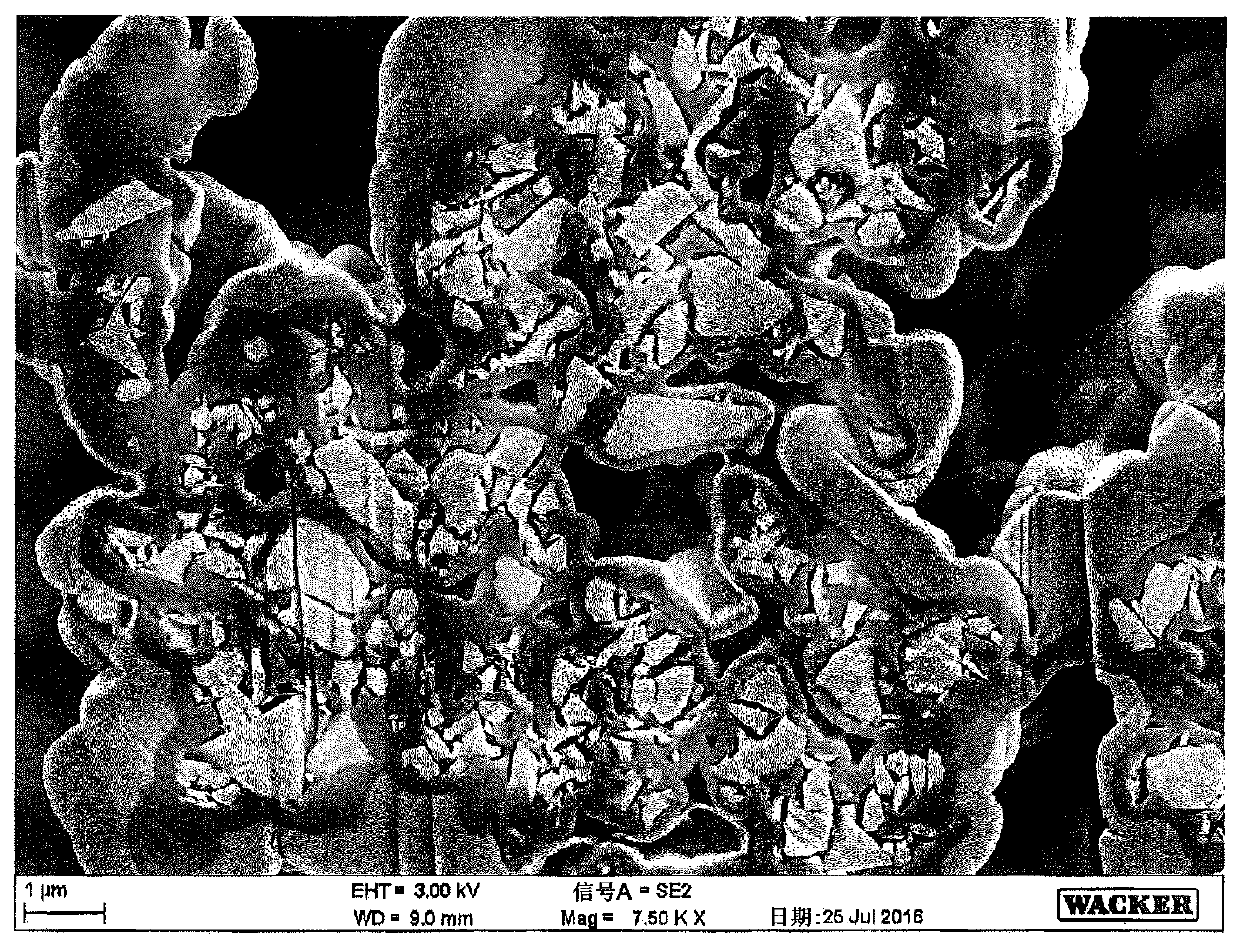

[0151] Core-shell composite particles (non-porous shell, core with local porosity, d of Si particles 50 =4.5μm):

[0152] a) Coating Si with sacrificial material

[0153] 15.0g silicon powder B(d 50 = 4.5 μm) in 90 ml of water and dispersed by ultrasound (Hielscher UIS 250V; amplitude 80%, period: 0.75; duration: 45 min). The resulting suspension was then added at 50° C. to a solution also at 50° C. of 5.2 g of melamine and 7.4 g of formaldehyde (20.0 g of a 37% strength aqueous solution) and stirred at 55° C. for 1 hour. Then 300 ml of dilute nitric acid (pH 3.5) were added, and the mixture was stirred at 100° C. for 60 minutes.

[0154] b) Coating the product from Example 2a with carbon precursors

[0155] 8.2 g of resorcinol and 6.7 g of formaldehyde (18.1 g of a 37% strength aqueous solution) were added to the product from example 2a with stirring. The pH was then adjusted to pH 7 by adding 2 ml of ammonia (32%), and the mixture was heated at 70° C. for 4 hours. ...

Embodiment 4

[0192] Electrochemical characterization of core-shell composite particles:

[0193] a) Preparation of electrode layers containing core-shell composite particles from Examples 1-3:

[0194] At 20°C, an aqueous solution of 0.17g of conductive carbon black (Imerys, Super C65), 3.0g of water and 6.05g of 1.4% by weight strength sodium carboxymethylcellulose (Daicel, Grade 1380) was passed through while cooling. The high speed mixer was dispersed for 5 minutes at a peripheral speed of 4.5 m / s and for 30 minutes at a peripheral speed of 17 m / s. Then add 0.21g SBR binder (styrene-butadiene copolymer, 40% in H 2 O), and then the mixture was dispersed again at a peripheral speed of 17 m / s for 30 minutes. Subsequently, 3.0 g of core-shell composite particles were added, stirred at a peripheral speed of 4.5 m / s for 5 minutes, and then dispersed at a peripheral speed of 12 m / s for another 30 minutes. After degassing, the dispersion was applied to a copper foil (Schlenk Metallfolien, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com