Preparation method and application of a derivatized functional porous wood for electrolyzing water to produce hydrogen

A technology of aquatic hydrogen production and functional pores, applied in electrolysis components, electrolysis process, electrodes, etc., can solve the problems of poor bonding between transition metal phosphide and wood substrate, complex process of transition metal phosphide, unstable interface, etc., and achieve good stability properties, improve efficiency, and reduce overpotential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

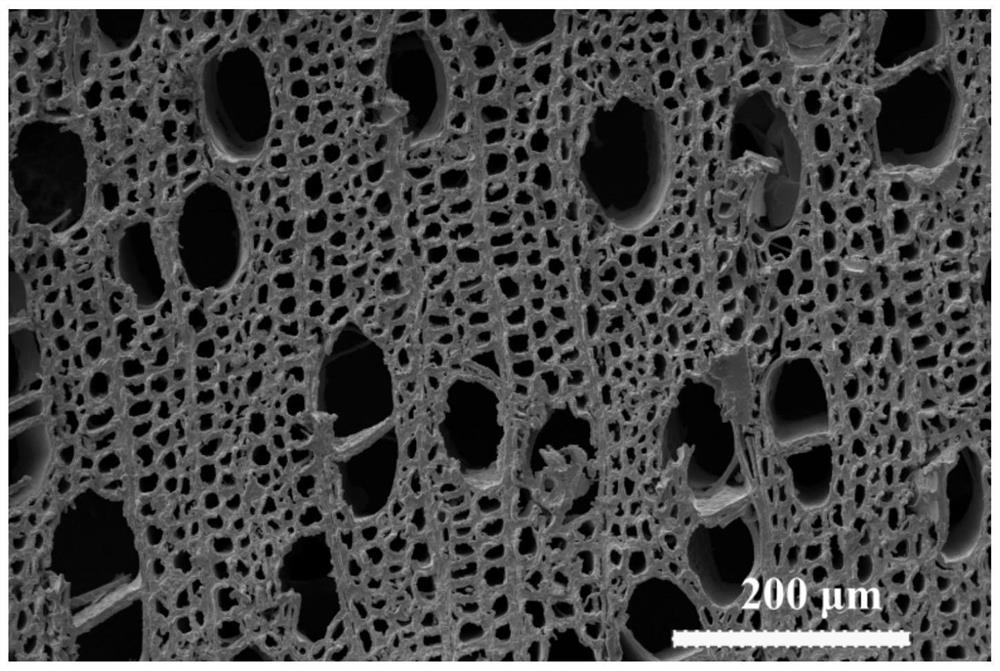

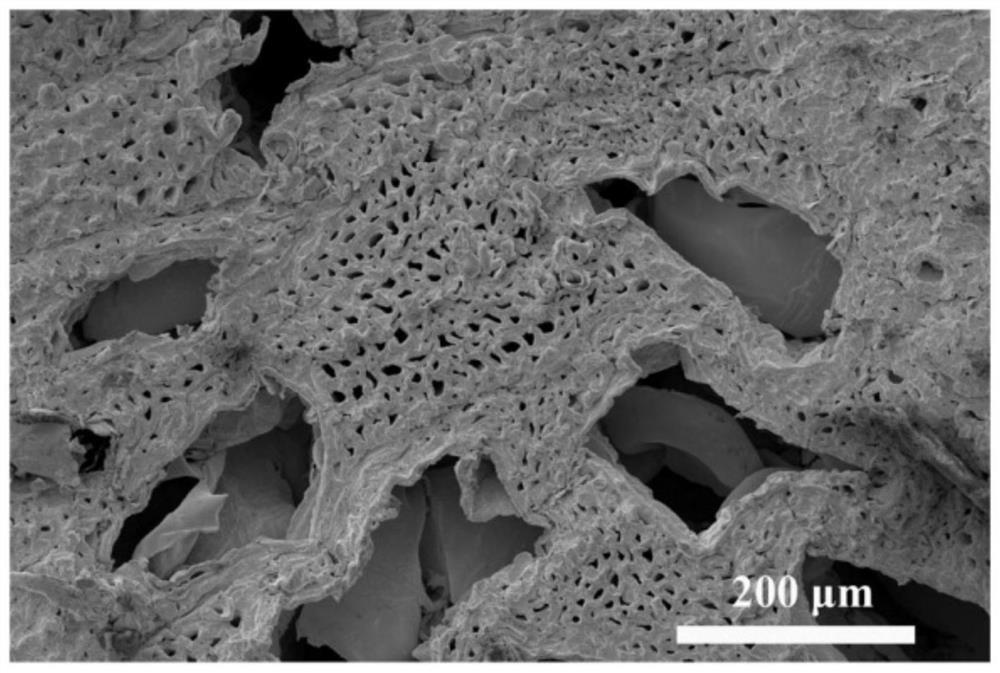

[0034] Specific implementation mode 1: This implementation mode is a preparation method of a derivatized functional porous wood used for electrolyzing water to produce hydrogen, which is completed according to the following steps:

[0035] 1. First remove the rough fibers on the surface of the natural porous wood, then ultrasonically clean it in deionized water, absolute ethanol and acetone in turn, and finally vacuum dry to obtain the natural porous wood with the rough fibers removed from the surface;

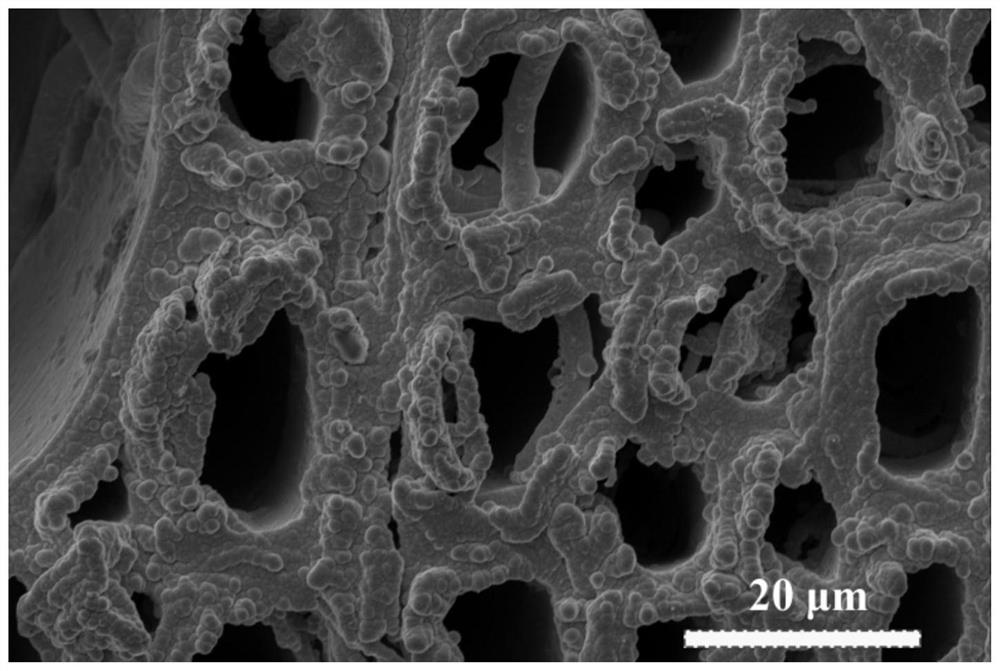

[0036] 2. Immerse the natural porous wood with surface rough fibers removed into PdCl with a concentration of 0.1g / L~0.3g / L 2 In hydrochloric acid solution for 10min to 20min, take it out and dry it with hot air to get loaded Pd 2+ porous wood;

[0037] 3. Immerse the porous wood loaded with Pd ions into NaBH with a concentration of 4g / L~6g / L 4 Sodium hydroxide solution for 5min to 15min, take it out and dry it with hot air to get loaded Pd 0 porous wood;

[0038] Fourth, ...

specific Embodiment approach 2

[0043] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the natural porous wood described in step 1 is poplar, Ash or larch, and the size is 1.5cm×1.0cm×0.1cm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step 1, first use 80 mesh sandpaper to polish the natural porous wood for 10min~20min, then use 240 mesh sandpaper to polish the natural porous wood for 10min~ 20min, to obtain the natural porous wood with surface coarse fibers removed. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com