Stone adhesive and preparation method thereof

A technology for adhesives and stone materials, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problem of inability to cover dark traces, yellow edges at the joint, and poor bond strength Large and other problems, to achieve the effect of easy operation, no yellowing, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

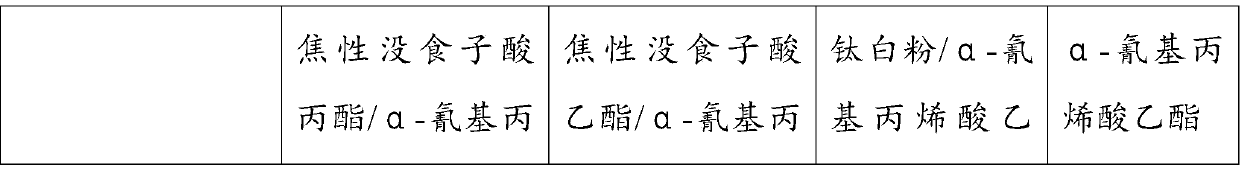

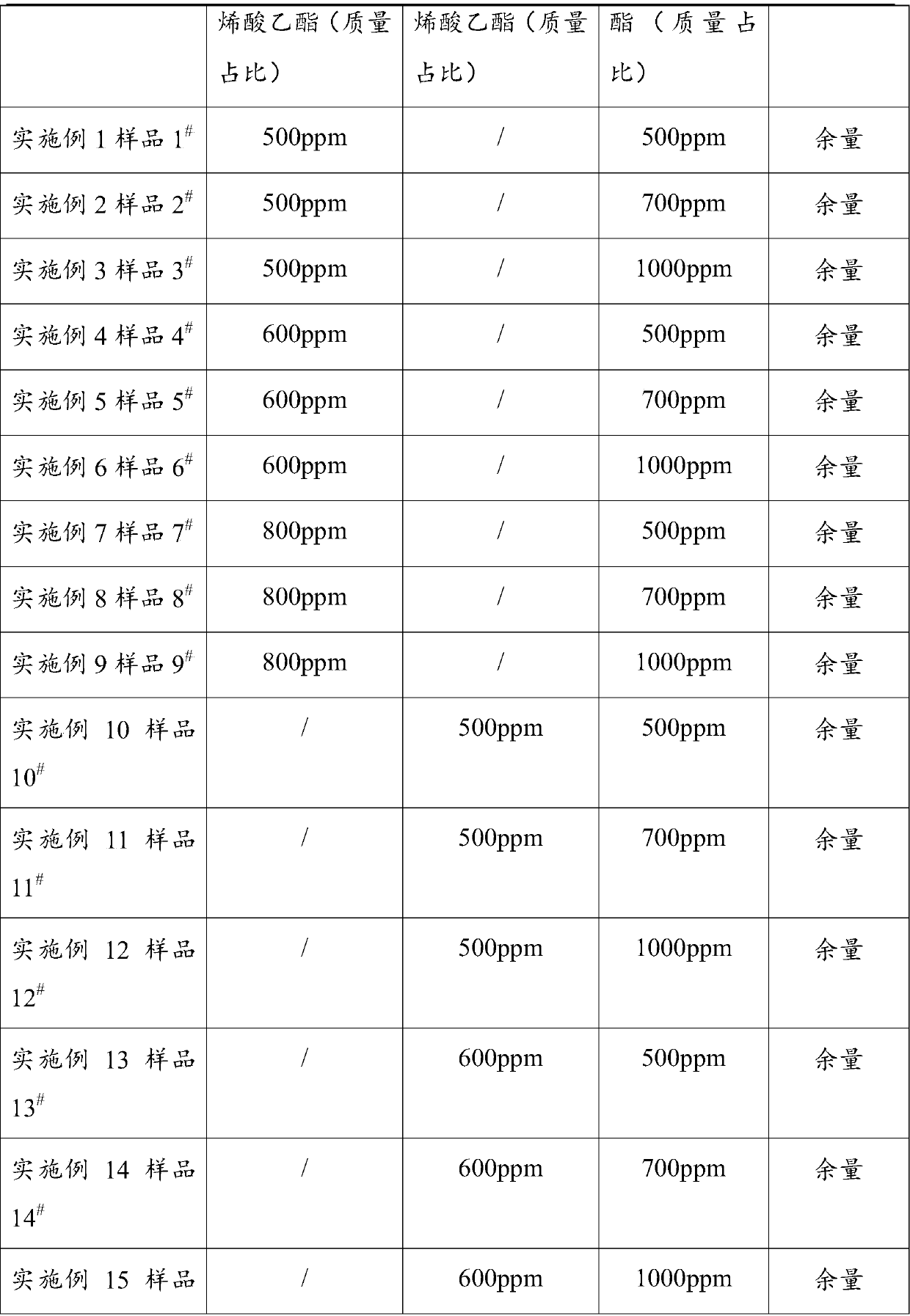

[0043] The preparation methods of each sample in Example 1 to Example 18 are as follows:

[0044] (1) Weigh α-ethyl cyanoacrylate, pyrogallic acid ester compounds (pyro gallic acid propyl ester or pyro gallic acid ethyl ester) and titanium dioxide according to the ratio of preparation;

[0045] (2) Weigh 10% from the weighed ethyl α-cyanoacrylate into a three-necked flask, then put the titanium dioxide into it, and stir to fully dissolve it in the ethyl α-cyanoacrylate;

[0046] (3) Add the remaining 90% ethyl cyanoacrylate and pyrogallic acid ester compound (pyro gallic acid propyl ester or pyro gallic acid ethyl ester), and stir at the reaction temperature of 40~60℃ for 24h , Get the required stone adhesive sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com