A kind of preparation technology of 2a14 aluminum alloy high tube parts

A preparation process, 2A14 technology, applied in the field of high-performance manufacturing process, can solve the problems of large size, reduce the anisotropy of high cylinder parts, reduce the plasticity of high cylinder parts, etc., to promote uniform dispersion precipitation, improve comprehensive mechanical properties, The effect of suppressing the dynamic recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

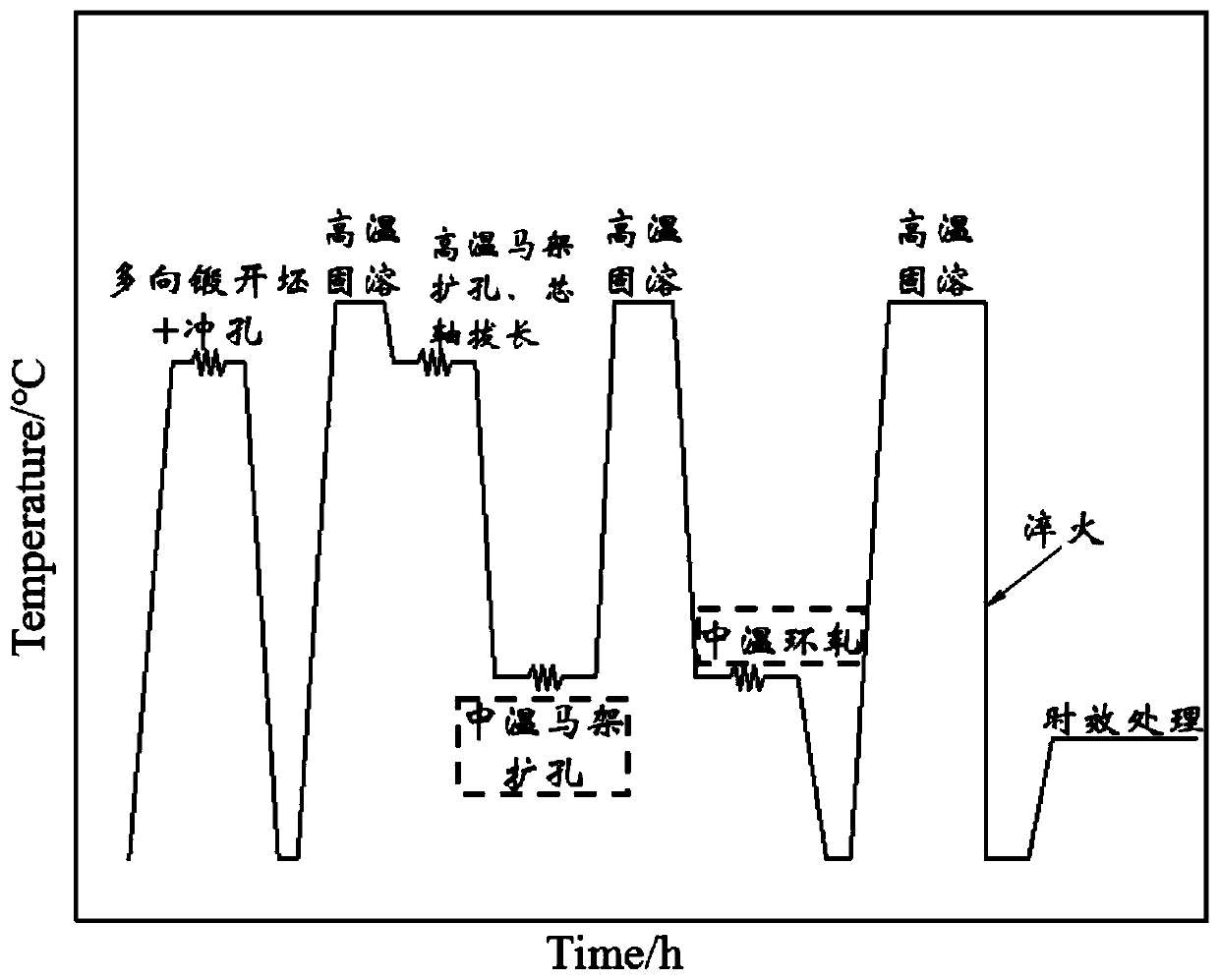

[0036] A kind of preparation technology of 2A14 aluminum alloy high cylinder part of the present invention, its flow chart is as follows figure 1 shown, including:

[0037] (1) Heat the homogenized 2A14 aluminum alloy ingot to 480°C±5°C in a resistance furnace, hold it for 2 hours, and then perform multi-directional forging on a hydraulic press (along the axial, radial, and tangential directions, respectively. Two times of upsetting and elongation, followed by rounding and axial leveling), in which both the upper and lower dies are heated to 400°C, the deformation of a single upsetting is 60%, and the final forging temperature is ≥380°C;

[0038] (2) Punch the blank after multi-directional forging on a hydraulic press, heat the punch used for punching to 380°C, and machine after punching to remove forging defects such as burrs and flashes;

[0039] (3) Heat the punched blank to 500°C±2°C in a resistance furnace, and keep it warm for 4h;

[0040](4) Firstly, the heated billet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com