Free-cutting aluminum copper alloy extruded bar and preparation method thereof

An aluminum-copper alloy, easy-cutting technology, applied in the field of aluminum-copper alloy extruded bar and its preparation, can solve the problem of high temperature brittleness, the cutting performance of aluminum-copper alloy extruded bar is difficult to meet the requirements of high-speed cutting processing of CNC machine tools, and the Poor corrosion performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A free-machining aluminum-copper alloy extruded rod, consisting of the following components in mass percentage: Cu 4.1%, Mg 0.8%, Mn 0.9%, Cr 0.5%, Ce 0.2%, B 0.08%, Ti 0.015%, C 0.0006%, Sn 1.1%, Bi0.4%, Fe≤0.2%, Si≤0.1%, the balance is Al and other impurity elements, the individual content of other impurity elements≤0.05%, the total ≤0.15%;

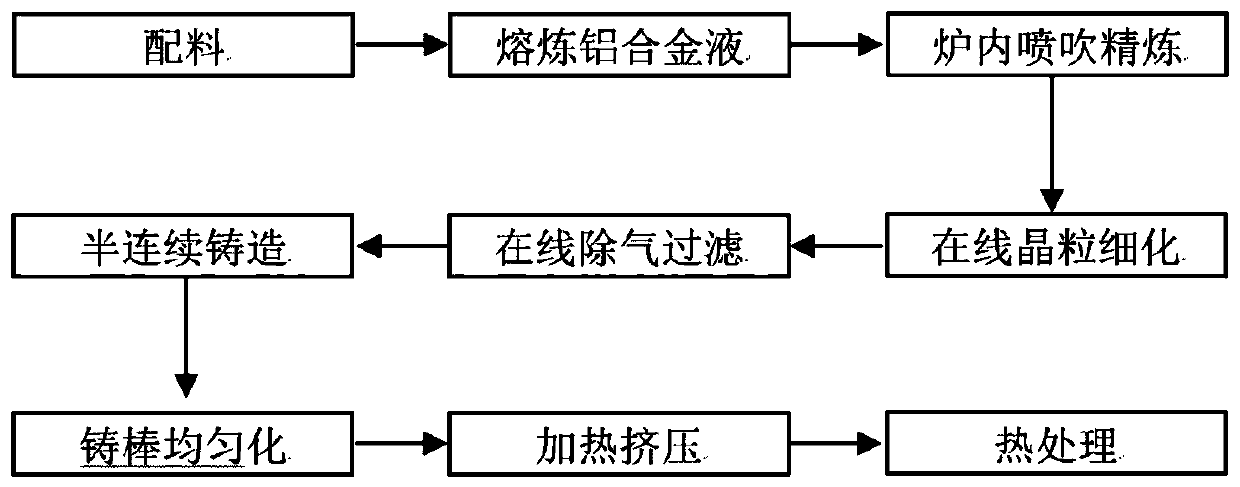

[0064] Its preparation method is as figure 1 shown, including the following steps:

[0065] S001: According to the composition and mass percentage of aluminum-copper alloy extruded rods, select aluminum ingots with 99.7% aluminum content, magnesium ingots with 99.95% magnesium content, tin ingots with 99.99% tin content, bismuth ingots with 99.99% bismuth content, AlCu50 alloy, AlMn10 alloy, AlCr10 alloy, AlCe5 alloy, AlB3 alloy and AlTi5C0.2 alloy wire are used as raw materials for batching;

[0066]S002: Place the aluminum ingot in a furnace with a permanent magnetic stirring device at the bottom of the furnace and heat and m...

Embodiment 2

[0075] A free-machining aluminum-copper alloy extruded rod, composed of the following components in mass percentage: Cu 3.5%, Mg 0.9%, Mn 0.6%, Cr 0.6%, Ce 0.25%, B 0.06%, Ti 0.01%, C 0.0004%, Sn 1.2%, Bi0.3%, Fe≤0.2%, Si≤0.1%, the balance is Al and other impurity elements, the individual content of other impurity elements≤0.05%, the total ≤0.15%;

[0076] Its preparation method comprises the following steps:

[0077] S001: According to the composition and mass percentage of aluminum-copper alloy extruded rods, select aluminum ingots with 99.7% aluminum content, magnesium ingots with 99.95% magnesium content, tin ingots with 99.99% tin content, bismuth ingots with 99.99% bismuth content, AlCu50 alloy, AlMn10 alloy, AlCr10 alloy, AlCe5 alloy, AlB3 alloy and AlTi5C0.2 alloy wire are used as raw materials for batching;

[0078] S002: Place the aluminum ingot in a furnace with a permanent magnetic stirring device at the bottom of the furnace and heat and melt at 760°C, then add m...

Embodiment 3

[0087] A free-machining aluminum-copper alloy extruded rod, consisting of the following components in mass percentage: Cu 4.5%, Mg 0.6%, Mn 1.0%, Cr 0.4%, Ce 0.15%, B 0.1%, Ti 0.02%, C 0.0008%, Sn 0.8%, Bi0.5%, Fe≤0.2%, Si≤0.1%, the balance is Al and other impurity elements, the individual content of other impurity elements is ≤0.05%, and the total amount is ≤0.15%;

[0088] Its preparation method comprises the following steps:

[0089] S001: According to the composition and mass percentage of aluminum-copper alloy extruded rods, select aluminum ingots with 99.7% aluminum content, magnesium ingots with 99.95% magnesium content, tin ingots with 99.99% tin content, bismuth ingots with 99.99% bismuth content, AlCu50 alloy, AlMn10 alloy, AlCr10 alloy, AlCe5 alloy, AlB3 alloy and AlTi5C0.2 alloy wire are used as raw materials for batching;

[0090] S002: Place the aluminum ingot in a furnace with a permanent magnetic stirring device at the bottom of the furnace to heat and melt at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com