Thermal-insulating coating containing hollow silica microspheres and application of coating

A technology of silicon dioxide and thermal insulation coatings, applied in the directions of silicon dioxide, silicon oxide, epoxy resin coatings, etc., can solve the problems of many thermal insulation coating additives, poor thermal insulation performance of thermal insulation coatings, etc. Thermal effect, not easy to drop powder, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

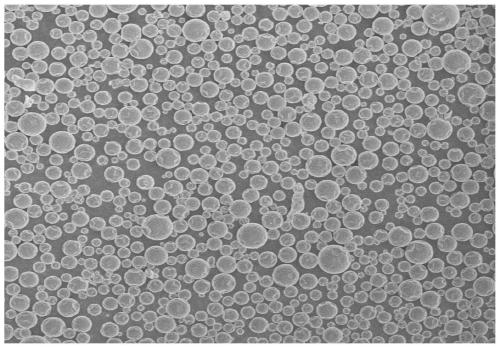

[0040] This embodiment provides a method for preparing hydrophilic hollow silica microspheres, including the following steps:

[0041] S1: Add methyltriethoxysilane (65g) to a mixed solution of ethyl orthosilicate (152g) and polyethylene glycol (9.4g) stirred at low speed (rotational speed is 200 rpm) and mix Evenly, add 20 grams of ethanol to the mixed solution to make it transparent; then slowly drop 25g of a hydrochloric acid solution with a concentration of 4.1 mol / L. After the addition is complete, the temperature is raised to 80°C, and the stirring reaction is continued for 4 hours. The ethanol in the system is quickly distilled off under reduced pressure to obtain a turbid prepolymer solution with a certain viscosity;

[0042] S2: Under stirring conditions (stirring speed is 500 rpm), add 20 grams of the above-mentioned prepolymer solution dropwise to 200 grams of distilled water to form an emulsion;

[0043] S3: After the dropwise addition of the prepolymer solution is compl...

Embodiment 2

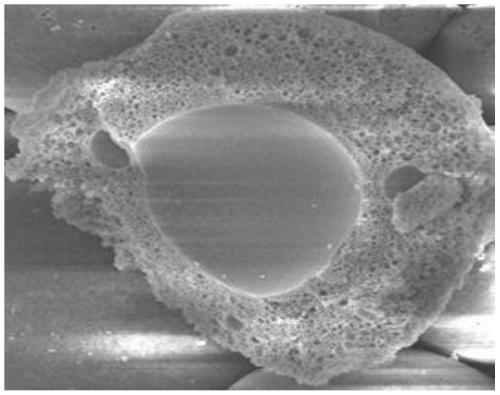

[0048] This embodiment provides a method for preparing hydrophobic hollow porous silica microspheres, including the following steps:

[0049] S1: Add r-aminopropyltriethoxysilane (84.7g) to a mixture of methyl orthosilicate (154g) and polyethylene glycol (8.2g) stirred at low speed (rotational speed is 200 rpm) Mix the solution uniformly, then add 30 g of isopropanol to the mixture to make it transparent; then slowly drop 32 g of sulfuric acid solution with a concentration of 2 mol / L. After the addition is complete, heat up to 80°C and continue stirring After reacting for 4 hours, the isopropanol in the system was quickly distilled off under reduced pressure to obtain a turbid prepolymer solution with a certain viscosity;

[0050] S2: Under stirring conditions (stirring speed is 500 rpm), add 20 grams of the above-mentioned prepolymer solution dropwise to 200 grams of distilled water to form an emulsion;

[0051] S3: After the dripping of the prepolymer solution is completed, add ac...

Embodiment 3

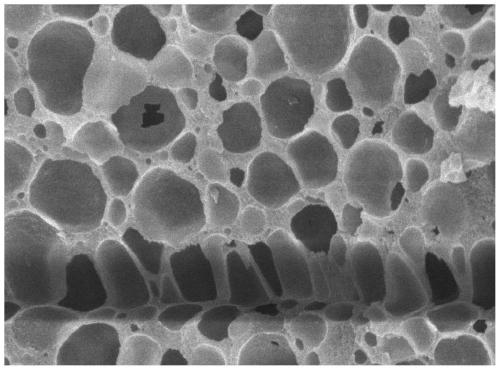

[0056] This embodiment provides a method for preparing hydrophilic hollow porous silica microspheres, including the following steps:

[0057] S1: Add vinyltrimethoxysilane (45.3g) to the mixed solution of isopropyl orthosilicate (151g) and polyethylene glycol (6.04g) stirred at low speed (rotational speed is 200 rpm) and mix Evenly, add 30 g of butanol to the mixture to make it transparent; then slowly drop 7.5 g of a hydrochloric acid solution with a concentration of 5.5 mol / L. After the addition is complete, the temperature is raised to 60°C, and the reaction is continued to be stirred 12 After hours, the film evaporates the butanol in the system to obtain a turbid prepolymer solution with a certain viscosity;

[0058] S2: Under stirring conditions (stirring speed is 200 rpm), add 20 grams of the above-mentioned prepolymer solution dropwise to 100 grams of distilled water to form an emulsion;

[0059] S3: After the dropwise addition of the prepolymer solution is completed, add for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com