Noise-reducing and shock-absorbing solid tire and preparation method thereof

A solid tire, noise reduction technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of poor shock absorption capacity of solid tires, large tire noise, and heavy weight of solid tires, and achieve shock absorption. Performance improvement, small deformation, good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

[0038] Activated carbon fibers in preparation example 1-3 are selected from the activated carbon fibers whose article number is txf-xw sold by Suzhou Charcoal Cyclone Activated Carbon Co., Ltd., and the glass fibers are selected from the glass fibers whose article number is 007 sold by Hejian Shilei Glass Fiber Cloth Factory, carbonized The silicon fiber is selected from the silicon carbide fiber of the brand DKnano sold by Beijing Deke Daojin Technology Co., Ltd., and the attapulgite is selected from the attapulgite with the item number 66 sold by Lingshou County Lingxin Mineral Products Factory, and the expanded perlite is selected from The expanded perlite and acrylic emulsion sold by Lingshou County Hengchuan Mineral Products Processing Factory with item number 35 were selected from the acrylic emulsion sold by Shanghai Xunda New Material Technology Co., Ltd. with the brand name HD-8426.

preparation example 1

[0039] Preparation Example 1: (1) According to the raw material ratio in Table 1, 0.3 kg of activated carbon fiber, 0.1 kg of expanded perlite and 0.2 kg of attapulgite were mixed and ground to form a powder with a particle size of 1 nm;

[0040] (2) Mix 3kg of glass fiber and 1kg of silicon carbide fiber and place it in a reactor at 250°C and stir for 10 minutes, add the ground powder and 0.2kg of acrylate emulsion in step (1), keep warm at 250°C and keep Stir for 20 minutes, take it out, and cool it down to obtain a noise-reducing material.

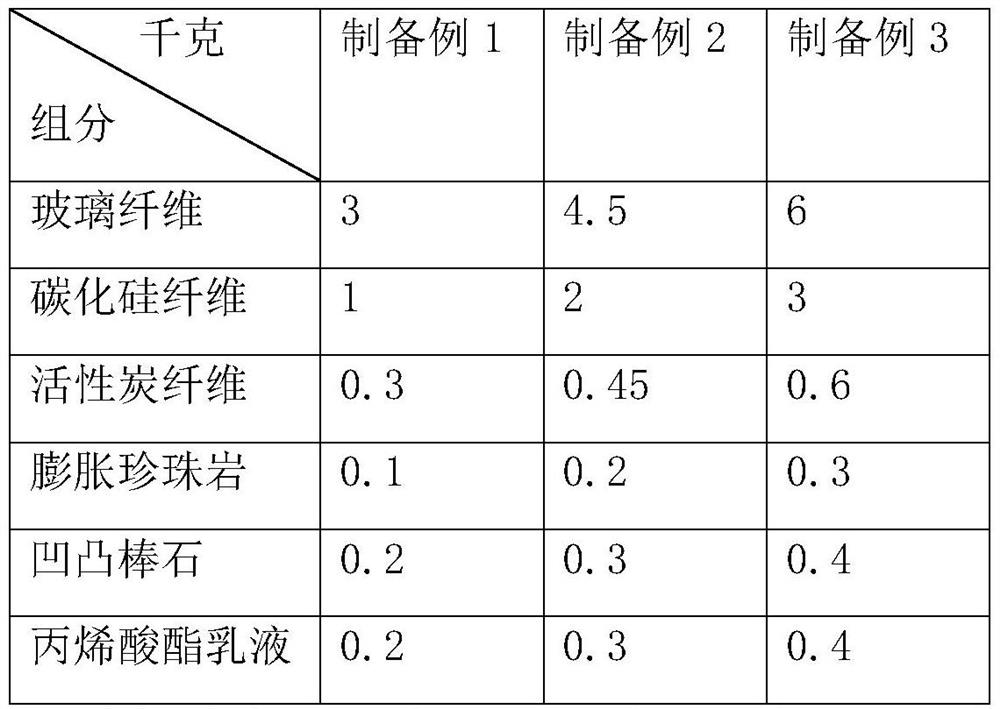

[0041] The raw material ratio of noise-reducing material in the preparation example 1-3 of table 1

[0042]

preparation example 2

[0043] Preparation Example 2: (1) According to the raw material ratio in Table 1, 0.45kg of activated carbon fiber, 0.2kg of expanded perlite and 0.3kg of attapulgite were mixed and ground to form a powder with a particle size of 3nm;

[0044] (2) Mix 4.5kg of glass fiber and 2kg of silicon carbide fiber in a reactor at 300°C and stir for 20 minutes, add the ground powder and 0.3kg of acrylate emulsion in step (1), keep warm at 300°C and Stir continuously for 30 minutes, take it out, and cool it down to obtain a noise-reducing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com