Processing method for increasing content of slow digestion starch of castanea henryi

A technology for digesting starch and a processing method, applied in the field of food processing, can solve the problems of time-consuming and labor-intensive efficiency, increased cost, low starch conversion rate, etc., and achieve the effects of improved taste, increased content and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] (1) Preparation of chestnut starch: after fresh chestnuts are shelled and uncoated, the chestnut kernels and distilled water are mixed and beaten at a mass ratio of 1:2, then filtered with a 200-mesh sieve, and the filter residue is returned to repeat the beating, and the filtrate is allowed to stand for stratification Discard supernatant after last, so repeat 2 times, obtain amylopsis starch precipitation;

[0028] (2) Ozone toughening treatment: Add distilled water to the starch precipitate obtained in step (1) to prepare starch milk, adjust its moisture content to 75%, and then place it in a vibrating shaker at a temperature of 50°C. Toughening treatment for 22 hours, during the treatment, the ozone gas produced by the ozone generator was continuously and stably introduced into the starch milk simultaneously to form the processed cornstarch milk; wherein the ozone generator was SK-CFG-1C ozone generator, with Ox...

Embodiment 2

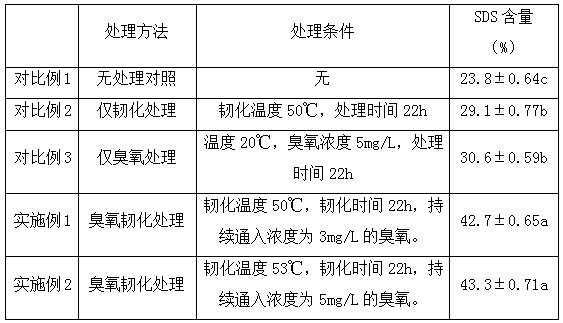

[0034] The difference between this example and Example 1 is that the concentration of ozone in the pumpkin starch milk described in step (2) is 5mg / L, and the toughening temperature is 53°C. After the treatment, the SDS content in the pumpkin starch is measured. , the results are shown in Table 1.

Embodiment 3

[0036] The difference between this example and Example 1 is that the pumpkin starch milk obtained in step (3) was placed in a high-voltage pulsed electric field device for 30 µs, and the SDS content in the pumpkin starch was measured after the treatment. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com