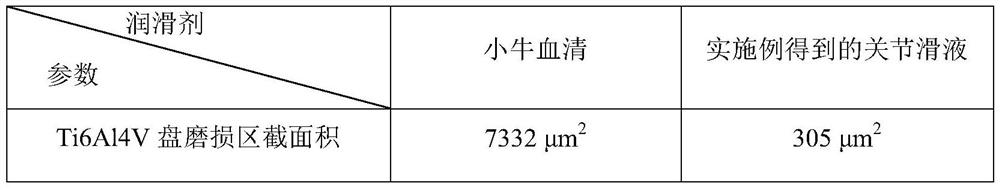

Joint synovial fluid preparation method for reducing wear of titanium alloy artificial joint materials

A technology for artificial joints and synovial fluid, which is used in pharmaceutical formulations, surgery, and drug delivery. Good performance and safety, and the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with specific embodiment:

[0015] Put 0.8g of N-isopropylacrylamide, 15mg of N,N'-methylenebisacrylamide, and 10mg of sodium dodecylsulfonate into a beaker containing 60mL of deionized water, and stir magnetically for 20 minutes to obtain a mixed solution. Then the mixed solution was added to the three-necked flask, and after the flask was sealed and evacuated, high-purity nitrogen gas was introduced until the pressure in the flask returned to 1 atm, and then 5 mL of 0.008 g / mL ammonium persulfate solution was added to the flask through a syringe. The reaction was carried out at 70° C. for 5 hours, and the prepared sample was dialyzed for 10 days, deionized water was replaced every 12 hours, and prepared into a 1.35 wt % poly-N-isopropylacrylamide solution for use. Next, 4 mL of 0.5 mol / L sodium azide solution was added to 20 mL of calf serum, and then 0.2 mol / L sodium phosphate was added to control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com