Method for recovering alkali, selenium and arsenic in arsenic-alkali residue from antimony smelting

A technology of arsenic-alkali slag and arsenic-alkali slag, which is applied in the field of antimony smelting arsenic-alkali slag disposal, selenium and arsenic, and recovery of alkali from arsenic-alkali slag, which can solve the problem of unrealized component recovery, unstable product components, and affecting glass quality and other issues, to achieve good economic and environmental benefits, high utilization, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

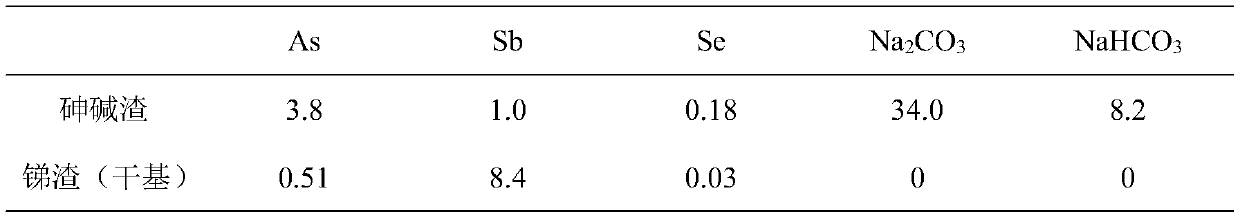

[0035] The method is used to treat the secondary arsenic-alkali slag of an antimony smelter in Hunan, and the moisture content of the arsenic-alkali slag is 31.2%. Break the arsenic-alkali slag to less than 5mm, then take 1.2kg of arsenic-alkali slag and leaching with water for 1 hour under the conditions of liquid-solid ratio 3mL / g, stirring speed 100r / min and leaching temperature 95°C, filter and wash to obtain antimony slag and arsenic-alkali solution. The alkali leaching rate of arsenic-alkali slag leaching and washing process is 100%, and the leaching rates of As, Sb and Se are 98.4%, 1.8% and 97.9%, respectively. Table 1 shows the content of relevant components in arsenic-alkali slag and antimony slag (dry basis), and Table 2 shows the content of relevant components in arsenic-alkali solution.

[0036] Table 1 Arsenic-alkali slag and antimony slag related component content (%)

[0037]

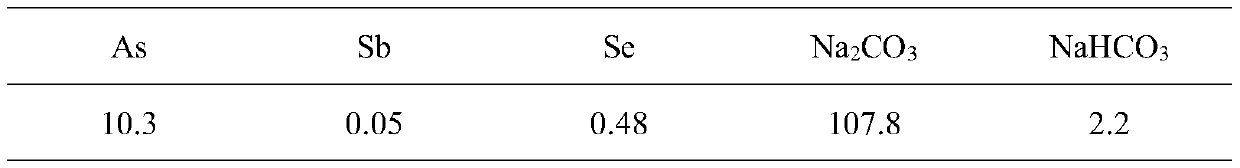

[0038] Related component content (g / L) in table 2 arsenic alkali solution

[0...

Embodiment 2

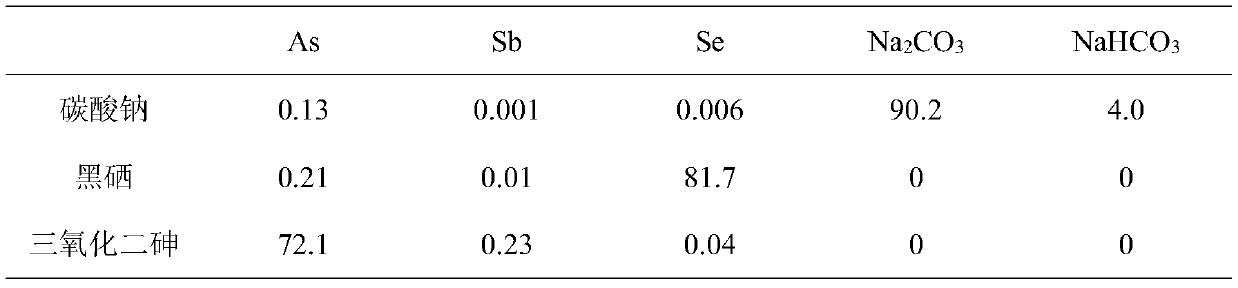

[0050] The experimental conditions of the arsenic-alkali slag used in this example, the leaching and washing of the arsenic-alkali slag, and the twice recovery of alkali by carbon dioxide are the same as those in Example 1. Adjust the pH of the secondary crystallization mother liquor to 2.9 with sulfuric acid, heat to 100° C. and keep the temperature for 20 minutes, and filter while it is hot to obtain black selenium and deselenized liquid. The direct yield of selenium is 81.3%, and the content of relevant components in black selenium is shown in Table 4. Show. CO produced during pH adjustment by sulfuric acid 2 Return to the alkali recovery process for recycling.

[0051] The solution after deselenization was fed with SO at 25°C and a stirring speed of 200r / min. 2 Reduce As(V) to As(III), then concentrate the reduced solution by 3.8 times, then cool and crystallize at 25°C, and filter to obtain crude arsenic trioxide and arsenic-removed solution. The direct yield of arsenic...

Embodiment 3

[0055] The method is used to treat the secondary arsenic-alkali slag of an antimony smelter in Hunan, and the moisture content of the arsenic-alkali slag is 29.1%. Crush the arsenic-alkali slag to less than 5mm, then take 1.2kg of arsenic-alkali slag and leaching with water for 1 hour under the conditions of liquid-solid ratio 3.5mL / g, stirring speed 100r / min and leaching temperature 105°C, filter and wash to obtain antimony slag and arsenic-alkali solution. The alkali leaching rate of arsenic-alkali slag leaching and washing process is 100%, and the leaching rates of As, Sb and Se are 99.4%, 2.1% and 98.9%, respectively. Table 5 shows the content of relevant components in arsenic-alkali slag and antimony slag (dry basis), and Table 6 shows the content of relevant components in arsenic-alkali solution.

[0056] Table 5 Arsenic-alkali slag and antimony slag related component content (%)

[0057]

[0058] Related component content (g / L) in table 6 arsenic-alkali mixed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com