Speed reducer input shaft machining process

A technology of processing technology and input shaft, which is applied in the field of processing technology of the input shaft of the reducer, can solve the problems that the hardness and strength of the inner spline 2 cannot meet the requirements, affect the product quality, and the fracture of the inner spline 2, etc., and achieve reliable clamping Durability, good wear resistance, and the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

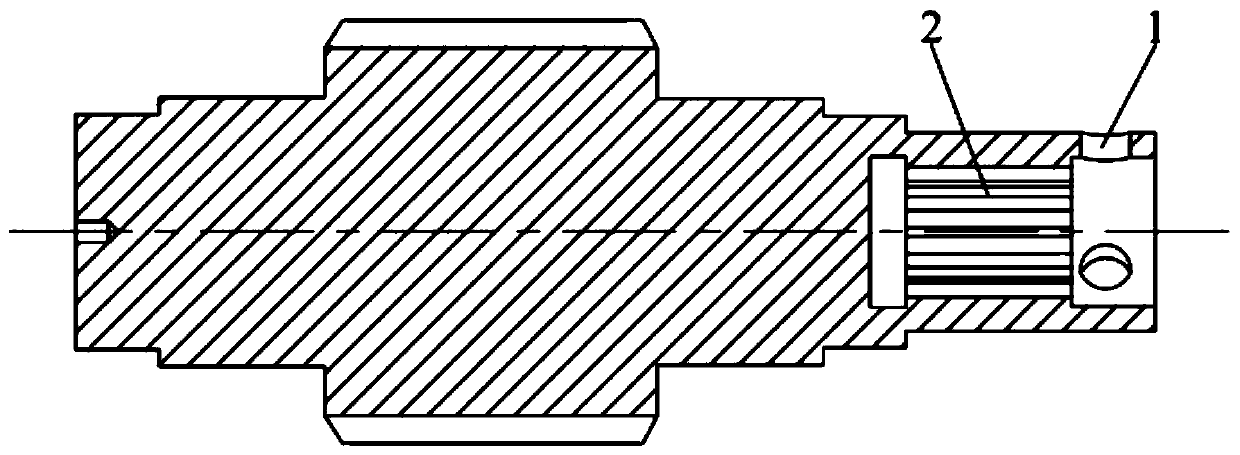

[0032] figure 1 It is the input shaft processed in the embodiment of the present invention, and the input shaft is provided with internal splines 2 and pin holes 1 arranged radially along the input shaft.

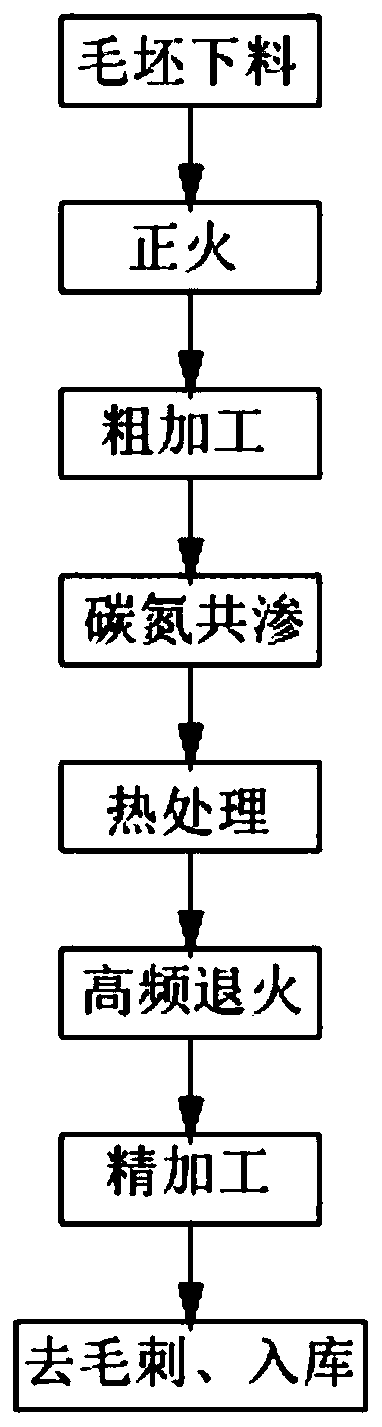

[0033] In order to reduce the deformation of the input shaft, increase the hardness of the inner spline 2, and further improve the quality and service life of the input shaft, the present invention provides a processing technology for the input shaft of a reducer, which includes the following steps:

[0034] 1) For blanking, forgings are selected for blanks. Forgings have greater toughness and rigidity, and are more economical. The blank material is 20CrMnTi, 20CrMnTi has good machinability, small processing deformation, good fatigue resistance, good machinability after normalizing, and is conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com