Exhaust system component

一种排气系统、组件的技术,应用在排气装置、发动机元件、管子/管接头/管件等方向,能够解决损害排气系统组件寿命等问题,达到避免机械压力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

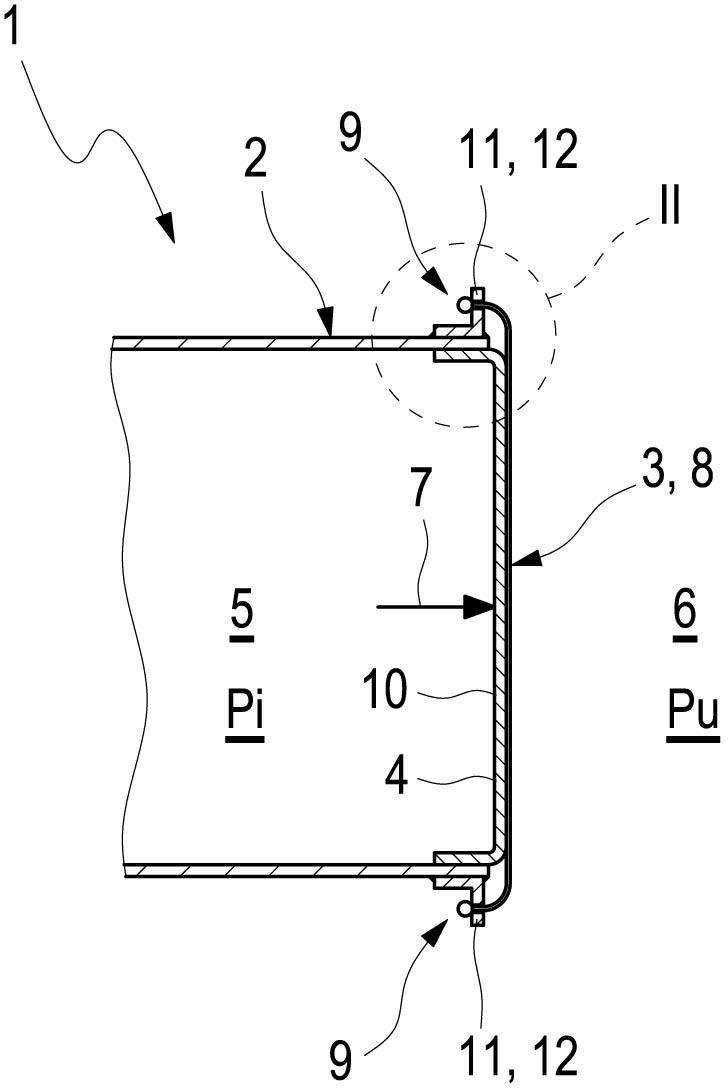

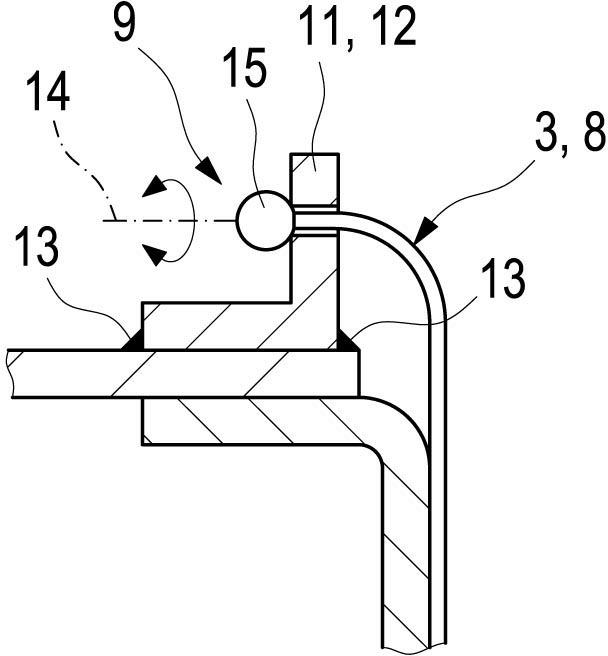

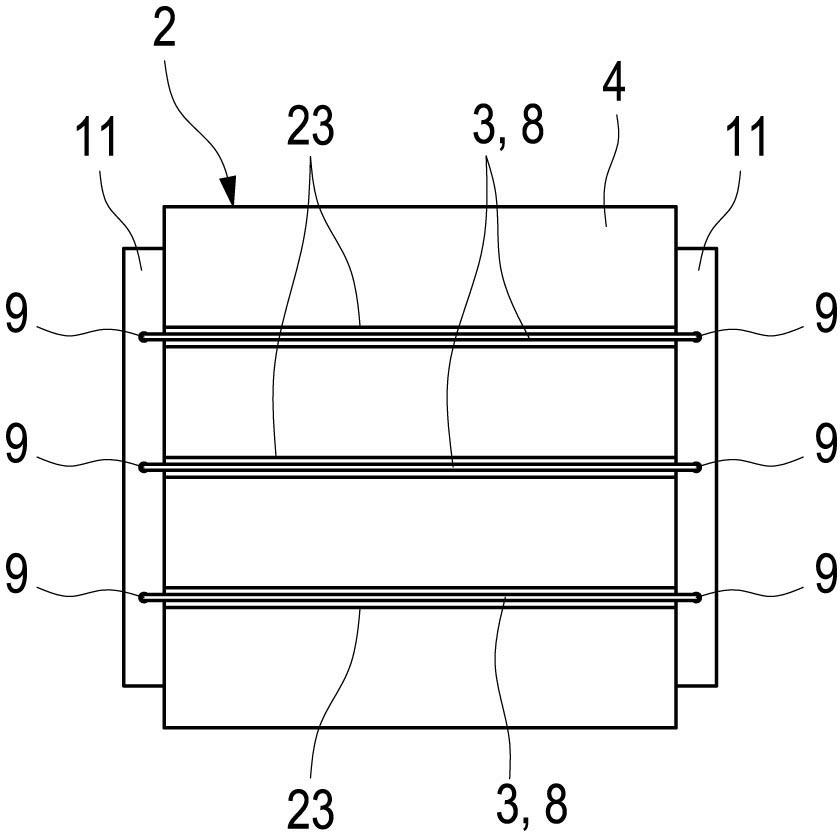

[0028] and Figures 1 to 11 Correspondingly, the exhaust system component 1 comprises a housing 2 and at least one stiffening element 3 . The exhaust system component 1 , which is also referred to below as component 1 , is used in an exhaust system of an internal combustion engine, preferably an exhaust system of a motor vehicle internal combustion engine, more preferably a commercial vehicle internal combustion engine. This component 1 is for example a muffler or an exhaust gas treatment device, like for example a particle filter, a catalytic converter, a NOx storage unit, a three-way catalytic converter or an SCR system. In principle, combinations of the aforementioned devices are also possible.

[0029]The housing 2 includes at least one housing wall 4 , which separates an interior 5 of the housing 2 from an environment 6 of the housing 2 . When the exhaust system is in operation, an internal pressure Pi is present in the interior space 5 and an ambient pressure Pu is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com