Synthesis method and application of monolithic nickel foam catalyst with 3D structure

A technology of a monolithic catalyst and a synthesis method, applied in the catalyst preparation technology and application field, can solve the problems of uneven distribution of active substances and easy aggregation, and achieve the effects of uniform distribution of active components, high catalytic activity, and overcoming the problem of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

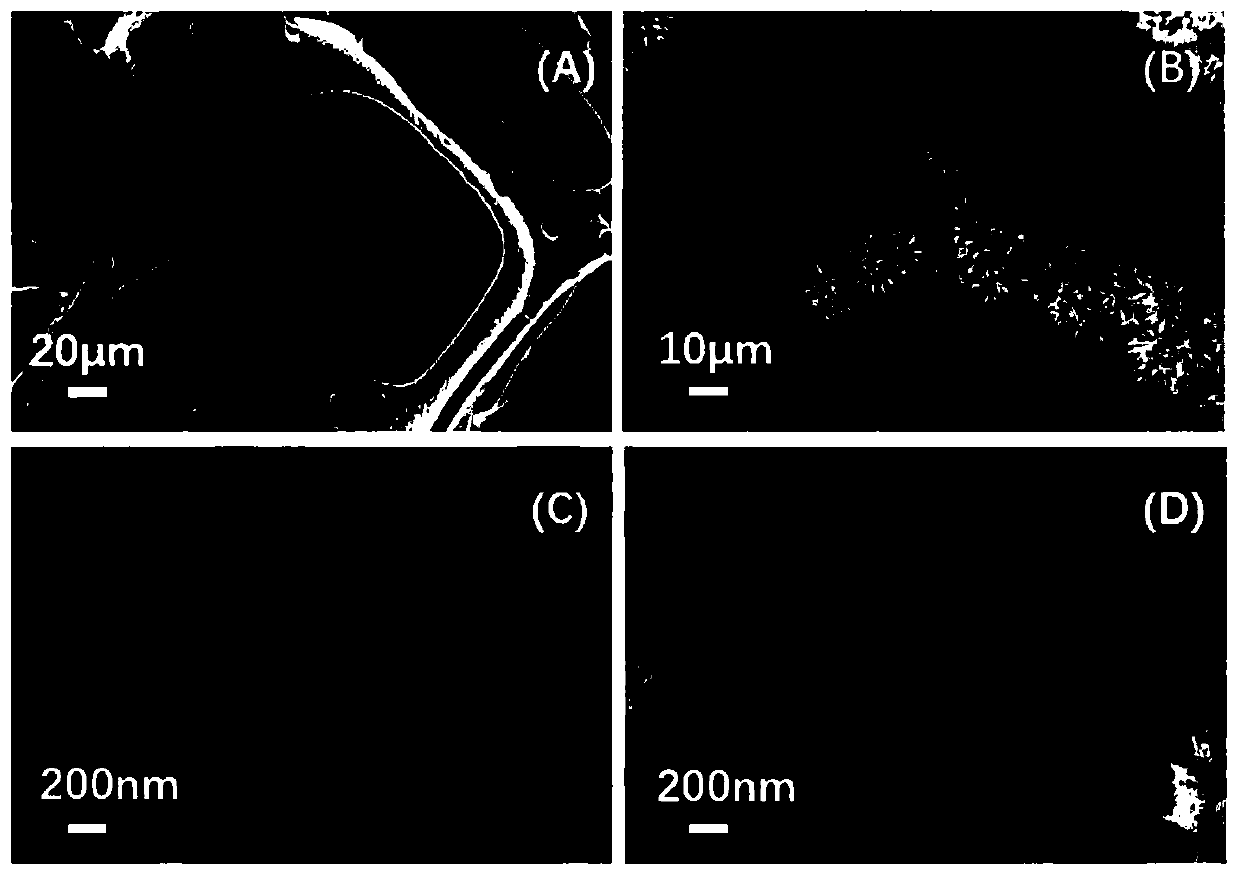

[0036] Embodiment 1: a kind of foamed nickel monolithic catalyst with 3D structure is synthesized, and concrete steps are as follows:

[0037] (1) Soak foamed nickel (length×width=3.7cm×2.0cm, thickness: 1.5mm) in 30mL 0.1mol / L hydrochloric acid solution for 2 minutes, then ultrasonically clean it with absolute ethanol and distilled water for 5 minutes respectively, so that Clean the nickel foam and dry it at 60°C for 3 hours for use;

[0038] (2) Take by weighing cobalt nitrate: urea: NH 4 Dissolve F=1:5:6 in 36mL distilled water, mix well, and prepare solution A;

[0039] (3) Place nickel foam in solution A and move it into a hydrothermal reaction kettle, and grow it at 80°C for 3 hours at a time;

[0040] (4) After the reaction finishes, take out the reaction kettle and open it after cooling to room temperature naturally, and the nickel foam obtains substance B after cleaning and drying;

[0041] (5) Calcining material B in a muffle furnace at a temperature of 300° C. fo...

Embodiment 2

[0045] Example 2: Synthesis and application of a nickel foam monolithic catalyst with a 3D structure, its basic steps are the same as in Example 1, except that cobalt nitrate in step (2): urea: NH 4 F=1:5:1, the difference is that the primary growth temperature in step (3) is 120°C, and the time is 10 hours; the roasting temperature in step (5) is 350°C, and the roasting time is 3 hours; step (6) permanganate The potassium concentration is 0.035 mol / L, the secondary growth temperature is 140° C., and the time is 24 hours; the subsequent steps are as in Example 1, and the catalyst B that catalyzes the oxidation of VOCs containing oxygen is obtained.

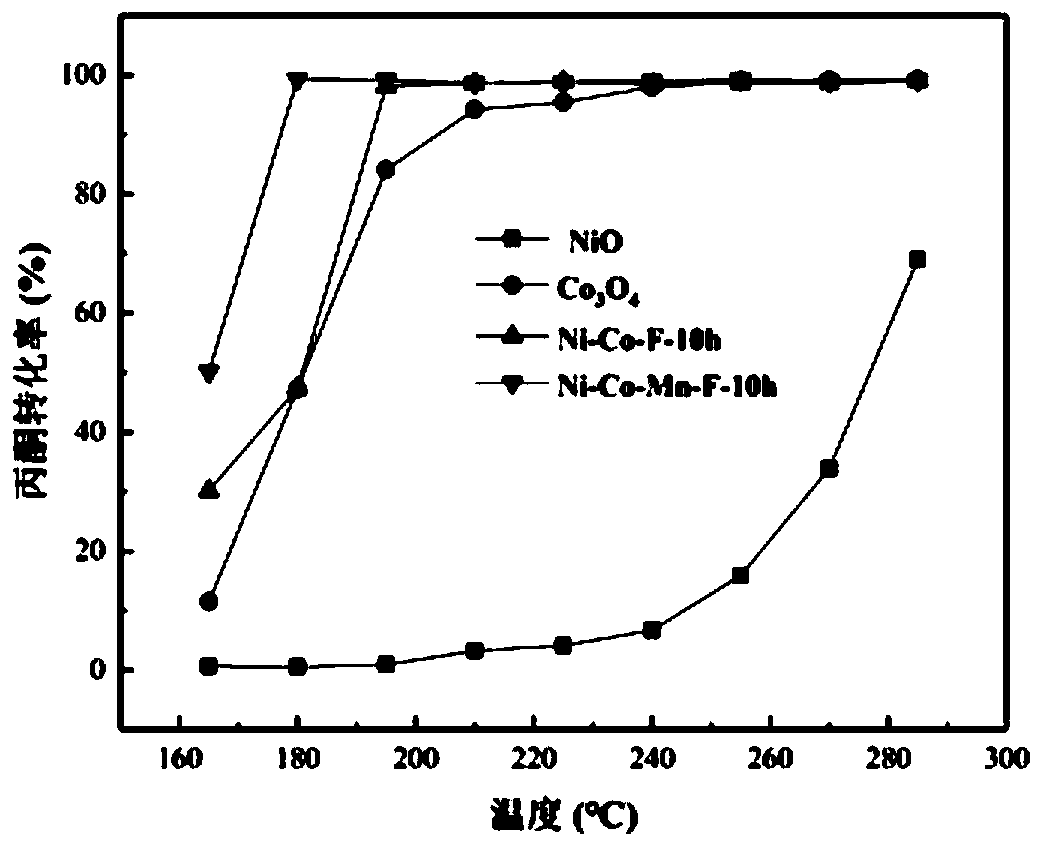

[0046] Prepared catalyst B carries out fixed-bed reaction, and mixed gas contains the VOCs (ethyl acetate) of 1000ppm, and at space velocity is 50000h -1 , The test is carried out under the condition that the reaction temperature is 100-400°C. After stabilization, measure the concentration of VOCs in the gas at the inlet and outl...

Embodiment 3

[0047] Example 3: Synthesis and application of a foamed nickel monolithic catalyst with a 3D structure, its basic steps are the same as in Example 1, except that cobalt nitrate in step (2): urea: NH 4 F: CTAB=5:25:20:4, the primary growth temperature in step (3) is 160°C, and the time is 16 hours; the roasting temperature in step (5) is 800°C, and the roasting time is 6 hours; step (6) high manganese Potassium acid concentration was 0.1 mol / L, the secondary growth temperature was 160° C., and the time was 36 hours; the subsequent steps were as in Example 1 to obtain catalyst C that catalyzes the oxidation of VOCs containing oxygen.

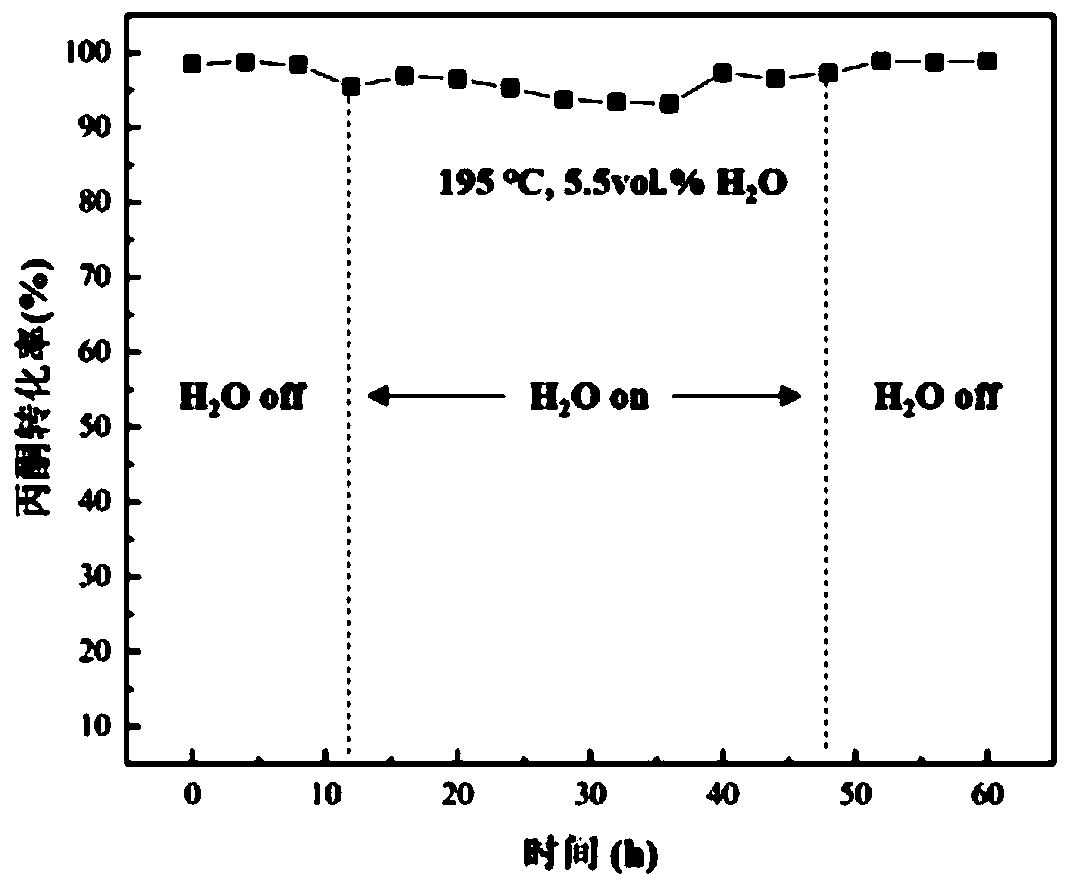

[0048] Prepared catalyst C carries out fixed-bed reaction, and mixed gas contains the VOCs oxygen-containing (acetone) of 2000ppm, and at space velocity is 2000h -1 , The test is carried out under the condition that the reaction temperature is 100-400°C. After stabilization, measure the concentration of VOCs in the gas at the inlet and outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com