Local acute bleeding-stopping absorbable material and preparation method thereof

An absorbent material and acute technology, applied in the field of biomedical composite materials, can solve the problems of weak antibacterial properties of oxidized regenerated cellulose, slow hemostasis, low tissue compatibility, etc., and achieve good market application prospects, easy absorption, and high degree of polymerization low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

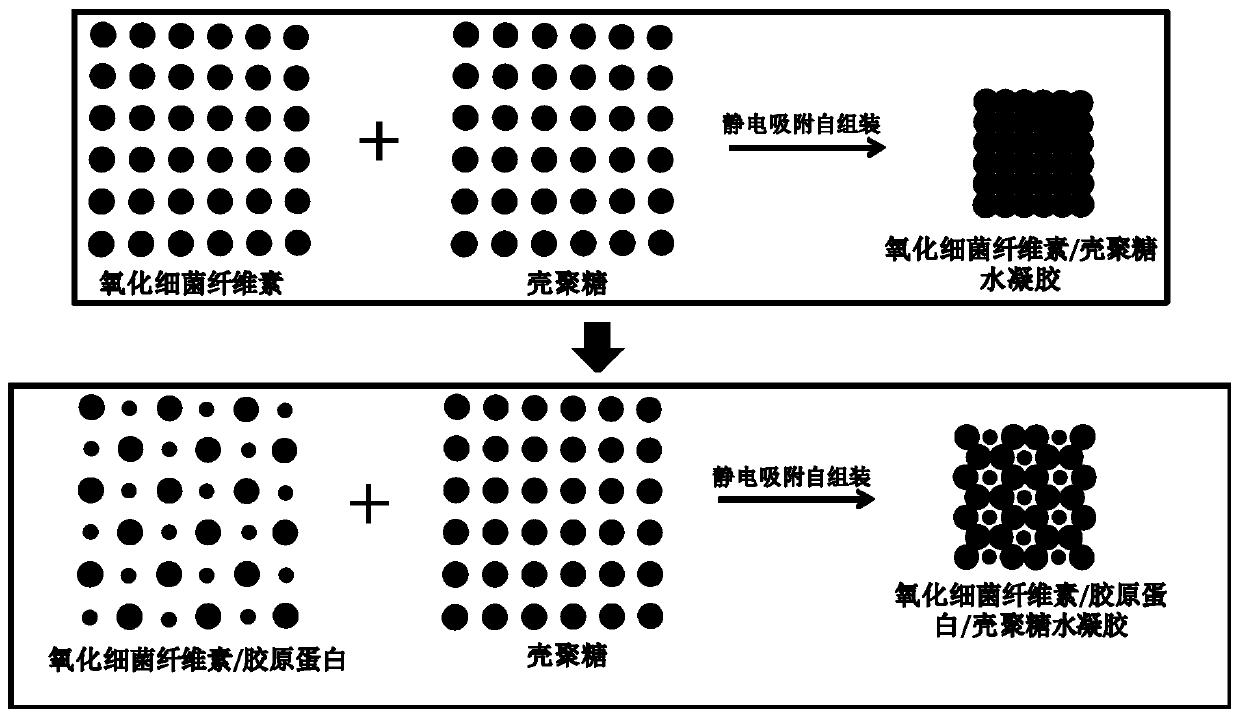

Method used

Image

Examples

Embodiment 1

[0031] (1) With Acetobacter xylinum as the strain, after static culture in liquid medium at constant temperature for 10 days, the bacterial cellulose membrane was taken out and placed in sodium hydroxide solution, treated at 80°C for 2 hours, taken out, rinsed with deionized water until Obtain bacterial cellulose film after neutralization; soak in hyaluronic acid solution for 6 hours to obtain bacterial cellulose film soaked in hyaluronic acid;

[0032] (2) Weigh 4 g of the purified bacterial cellulose membrane, shred it and disperse it in a high-speed homogenizer to become a bacterial cellulose suspension.

[0033] (3) The bacterial cellulose suspension obtained in step (2) (solid content is 1-10g / L) is oxidized at room temperature through TEMPO / NaBr / NaClO mixed oxidation system, TEMPO consumption is 0.1mmol / g, NaBr It is 1 mmol / g. A certain amount of 10% NaClO solution was added to start the reaction, and 0.5M NaOH solution was added dropwise to maintain the pH of the react...

Embodiment 2

[0036] (1) With Acetobacter xylinum as the strain, after static culture in liquid medium at constant temperature for 10 days, the bacterial cellulose membrane was taken out and placed in sodium hydroxide solution, treated at 80°C for 2 hours, taken out, rinsed with deionized water until Obtain bacterial cellulose film after neutralization; soak in hyaluronic acid solution for 6 hours to obtain bacterial cellulose film soaked in hyaluronic acid;

[0037] (2) Weigh 4 g of the purified bacterial cellulose membrane, shred it and disperse it in a high-speed homogenizer to become a bacterial cellulose suspension.

[0038] (3) The bacterial cellulose suspension obtained in step (2) (solid content is 1-10g / L) is oxidized at room temperature through TEMPO / NaBr / NaClO mixed oxidation system, TEMPO consumption is 0.1mmol / g, NaBr It is 1 mmol / g. A certain amount of 10% NaClO solution was added to start the reaction, and 0.5M NaOH solution was added dropwise to maintain the pH of the react...

Embodiment 3

[0042] (1) With Acetobacter xylinum as the strain, after static culture in liquid medium at constant temperature for 10 days, the bacterial cellulose membrane was taken out and placed in sodium hydroxide solution, treated at 80°C for 2 hours, taken out, rinsed with deionized water until Obtain bacterial cellulose film after neutralization; soak in hyaluronic acid solution for 6 hours to obtain bacterial cellulose film soaked in hyaluronic acid;

[0043] (2) Weigh 4 g of the purified bacterial cellulose membrane, shred it and disperse it in a high-speed homogenizer to become a bacterial cellulose suspension.

[0044] (3) The bacterial cellulose suspension obtained in step (2) (solid content is 1-10g / L) is oxidized at room temperature through TEMPO / NaBr / NaClO mixed oxidation system, TEMPO consumption is 0.1mmol / g, NaBr It is 1 mmol / g. A certain amount of 10% NaClO solution was added to start the reaction, and 0.5M NaOH solution was added dropwise to maintain the pH of the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com