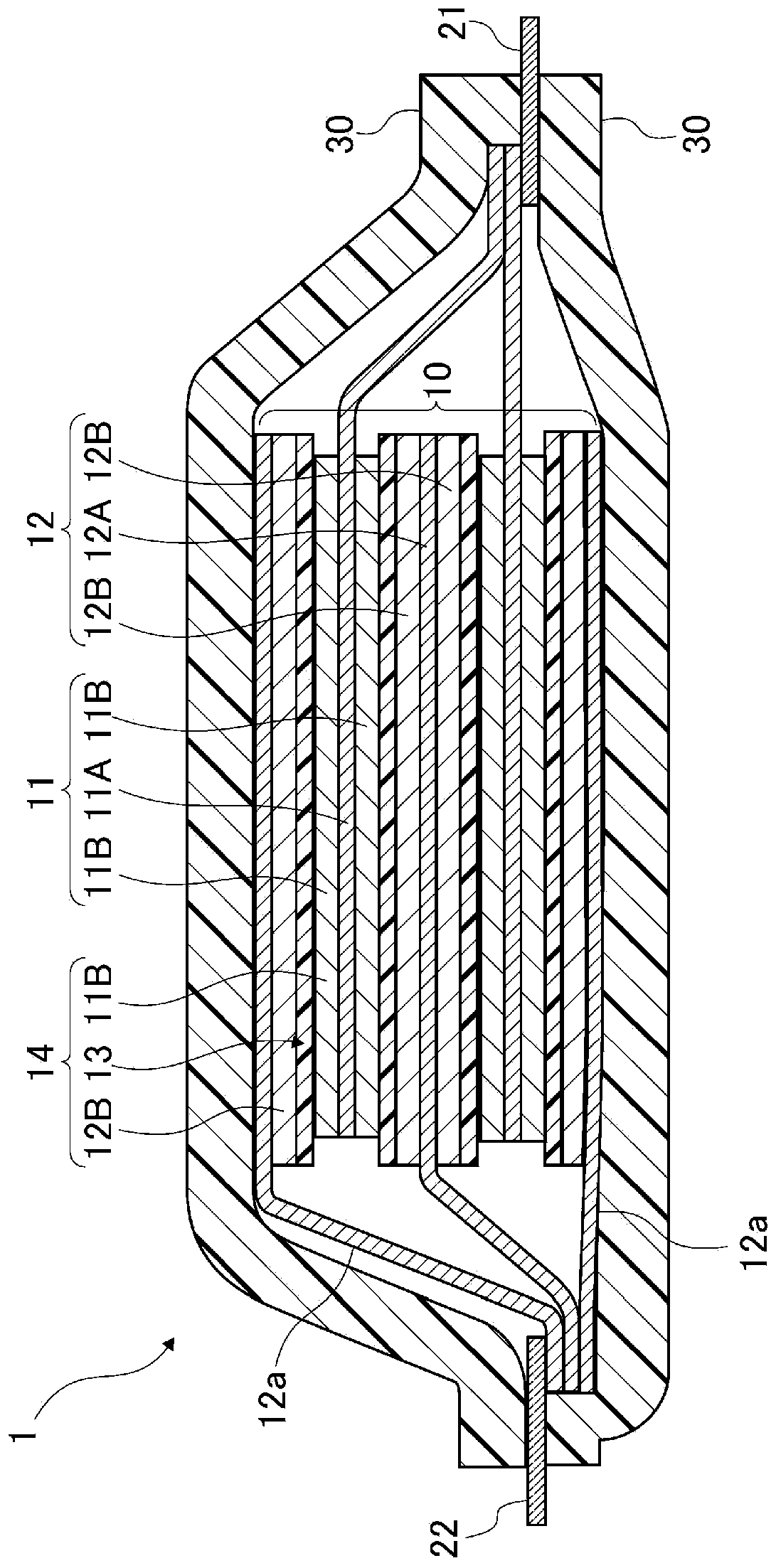

Non-aqueous electrolyte secondary battery and material for use in same

A non-aqueous electrolyte, secondary battery technology, applied in secondary batteries, battery electrodes, electrode current collector coatings, etc., can solve the problems of unsatisfactory, different degrees of deformation, deterioration of the current collection structure of the positive electrode mixture layer, etc. Effects of improved performance, suppression of thermal runaway, and increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0176] Binder-Solution Preparation

[0177] 10 g of PMMA (molecular weight: 15,000) was added to 115 g of N-methylpyrrolidone (NMP), and stirred for 12 hours to prepare an 8%-PMMA solution. 125 g of the 8%-PMMA solution and 375 g of the 8%-PVDF solution (PVDFW#7200 manufactured by Kureha dissolved in NMP) were mixed and stirred for 12 hours. Thus, an 8%-binder solution (PVDF:PMMA=3:1) was obtained.

[0178] Positive electrode production

[0179] 1. Slurry Preparation

[0180] The slurry was prepared using a 5 L planetary mixer.

[0181] For NCM523 (manufactured by Umicore, the composition formula is LiNi 0.5 co 0.2 mn 0.3 o 2 ) 920g, Super-P (conductive carbon manufactured by TIMCAL Co., Ltd.) 20g, and KS-6 (flaky graphite manufactured by TIMREX Co., Ltd.) 20g were mixed for 10 minutes, and N-methylpyrrolidone (NMP) 100g was added for a further 20 minutes mix.

[0182] Next, 150 g of the 8%-binder solution was added and kneaded for 30 minutes, and then 150 g of th...

Embodiment 2

[0212] The positive electrode roll produced in the same manner as in Example 1 was cut into electrodes so as to obtain electrode coating areas (front and back: 174 mm×94 mm) and tab welding blanks to obtain positive electrodes C-2.

[0213] The negative electrode roll produced in the same manner as in Example 1 was divided into electrodes so as to obtain electrode coating areas (front and back: 180 mm×100 mm) and tab welding blanks to obtain negative electrodes A-2.

[0214] battery production

[0215] Laminated battery (design capacity is 5Ah)

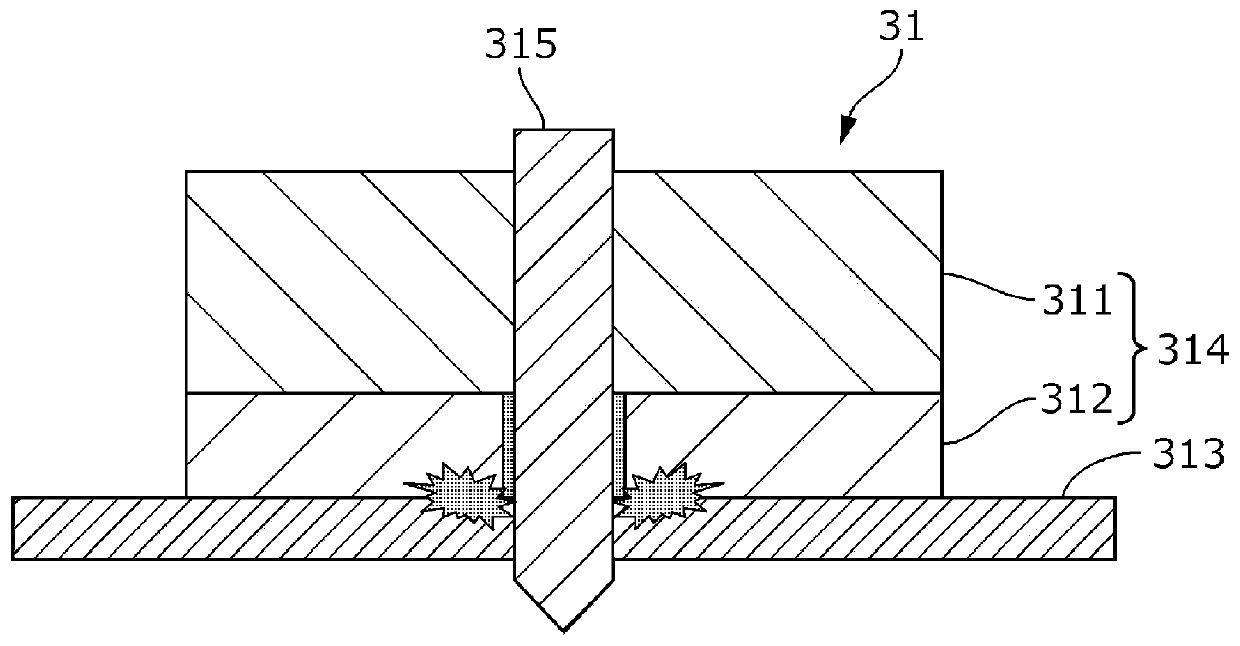

[0216] An aluminum tab was bonded to the blank portion of the positive electrode C-2 using an ultrasonic bonding machine. A nickel tab was bonded to the blank portion of the negative electrode A-2 using an ultrasonic bonding machine.

[0217] 1. Cascading

[0218] As the separator, a polyethylene porous membrane (183 mm×100 mm) with a porosity of 45% and a thickness of 25 μm was used (S-2).

[0219] In the order of negative electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com