Preparation method and application of carbon nanofibers

A carbon nanofiber and nanofiber membrane technology, applied in the field of carbon nanofiber preparation, can solve the problems of difficult control, cumbersome processing steps, inability to greatly improve the electrochemical performance of electrodes, etc. The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing carbon nanofibers, comprising the following steps:

[0027] Mix carbon source, starch and organic solvent to obtain precursor solution;

[0028] Electrospinning the precursor solution to obtain a nanofibrous membrane;

[0029] The nanofiber film is subjected to pre-oxidation treatment and carbonization treatment in sequence to obtain carbon nanofibers.

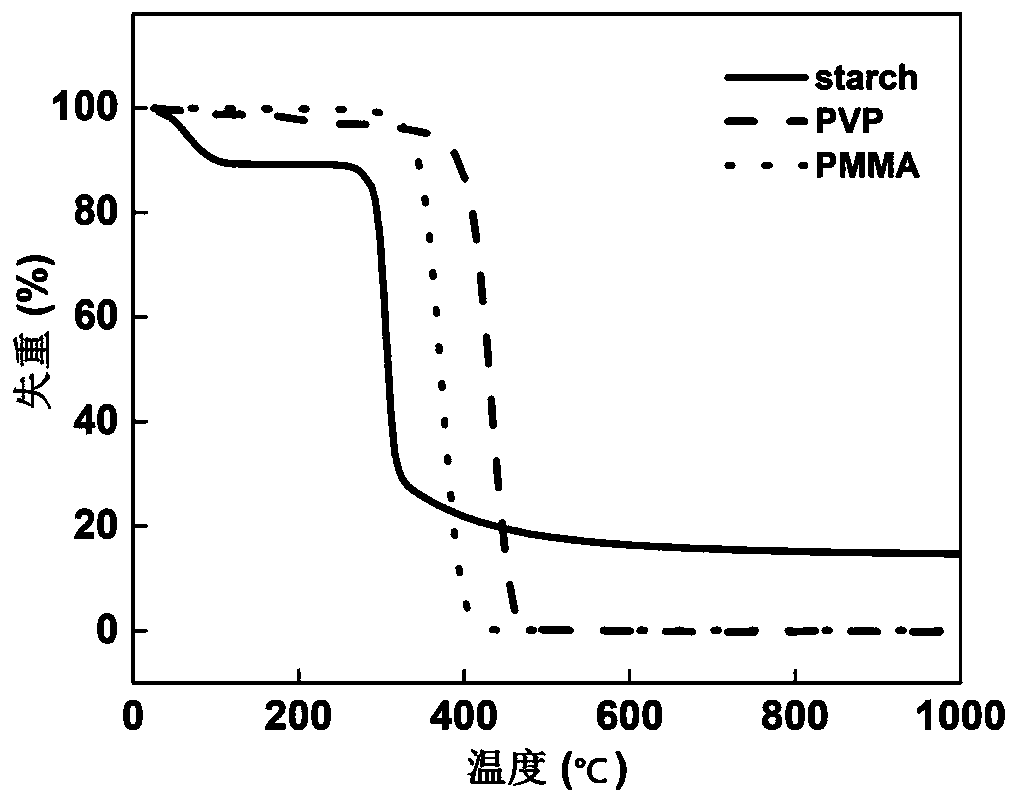

[0030] The invention mixes carbon source, starch and organic solvent to obtain precursor solution. In the present invention, the carbon source preferably includes one or more of polyacrylonitrile, pitch, lignin, phenolic resin, polyimide and polybenzimidazole, more preferably polyacrylonitrile, lignin or Polyimide, most preferably polyacrylonitrile. In the present invention, the starch preferably includes one or more of high amylose, high amylopectin and potato starch, more preferably high amylose or high amylopectin. In the present invention, the mass ratio of the carbo...

Embodiment 1

[0045] Mix polyacrylonitrile (PAN) and starch (mass ratio of polyacrylonitrile to starch: 8:2), dissolve in dimethyl sulfoxide, place in a conical flask, stir in a water bath at 60°C for 24h, Get a precursor solution with a total mass concentration of 10%, put the precursor solution into a syringe for standby; paste aluminum foil paper on the drum of the electrospinning machine, and set the spinning parameters: the receiving distance is 15cm, and the advancing speed is 1mL / h, the voltage is 20kV, the drum speed is 100rpm, and the ambient temperature is controlled at 40°C, and the precursor solution is electrospun to obtain a nanofiber film;

[0046] The nanofiber membrane is subjected to pre-oxidation treatment and carbonization treatment, and the parameters of the pre-oxidation process are set as follows: in the air environment, the temperature is raised to 260 ° C at a heating rate of 2 ° C / min, and the temperature is maintained for 60 min; the carbonization process parame...

Embodiment 2

[0058] Mix polyimide and starch (mass ratio of polyacrylonitrile to starch: 7:3) and dissolve in dimethyl sulfoxide, place in an Erlenmeyer flask, stir in a water bath at 50°C for 10 hours, and obtain the total mass Precursor solution with a concentration of 9%, put the precursor solution into a syringe for standby; paste aluminum foil paper on the drum of the electrospinning machine, and set the spinning parameters: the receiving distance is 20cm, and the advancing speed is 1.5mL / h , the voltage is 18kV, the drum speed is 150rpm, and the ambient temperature is controlled at 50°C, and the precursor solution is electrospun to obtain a nanofiber film;

[0059] The nanofiber membrane is subjected to pre-oxidation treatment and carbonization treatment, and the parameters of the pre-oxidation process are set as follows: in the air environment, the temperature is raised to 240 ° C at a heating rate of 3 ° C / min, and the temperature is kept for 30 min; the carbonization process para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com