mos 2 QDs fluorescent probe, its synthesis method and application

A fluorescent probe and synthesis method technology, applied in the field of biological fluorescent probes and transition metal sulfide quantum dot biological fluorescent probes, can solve the problems of easy oxidation, low quantum yield of fluorescent probes, and cumbersome production process of fluorescent probes etc. to achieve strong anti-corrosion properties, improve anti-oxidation and photo-bleaching properties, and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

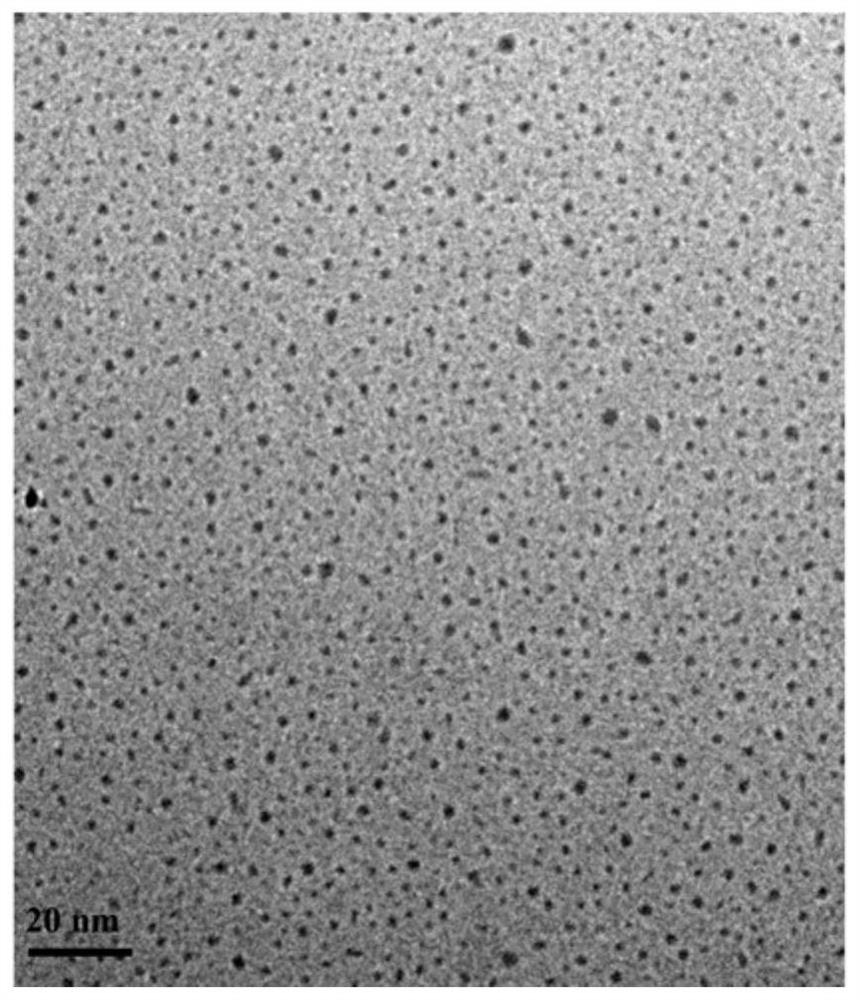

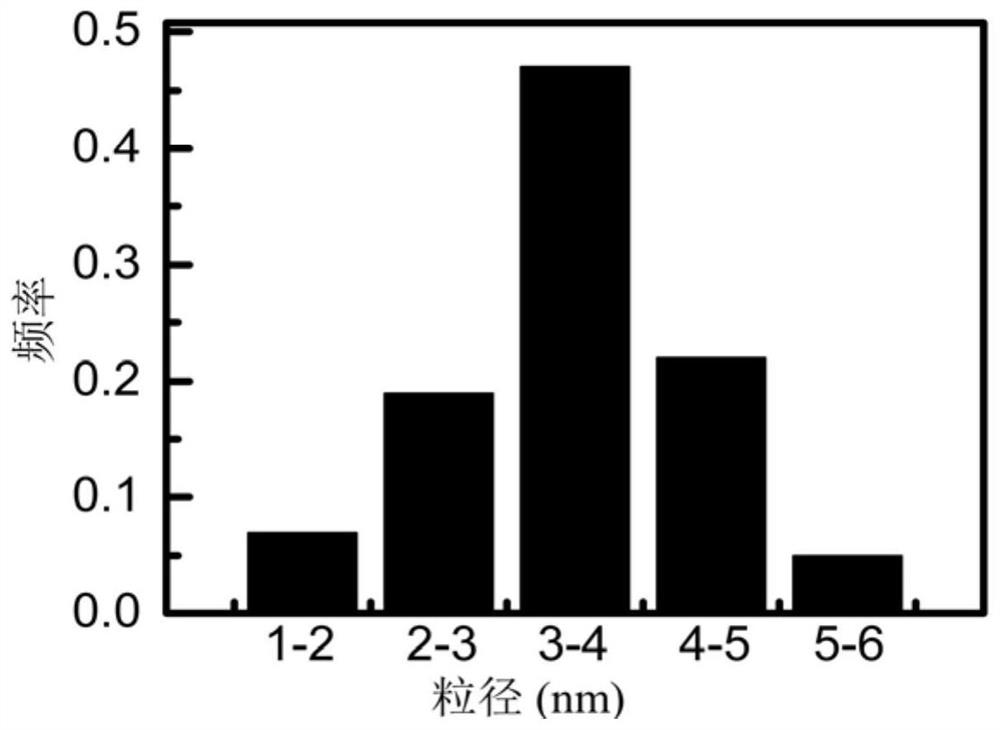

[0060] (1)MoS 2 Preparation of quantum dot powder

[0061] 1) Dissolve 0.225 g and 0.13 g of cystamine dihydrochloride and ammonium tetrathiomolybdate in 36 mL of deionized water, and adjust the pH value of the mixed solution to 7 with ammonia water or hydrochloric acid.

[0062] 2) After the above mixed solution was sonicated for 25 minutes, it was transferred into a 50 mL stainless steel reaction kettle with a polytetrafluoroethylene liner, heated at 200° C., and reacted for 16 hours.

[0063] 3) After the reaction is completed, the reactor is left to stand for 5 minutes. Take the supernatant suspension, and use a high-speed centrifuge to centrifuge at a speed of 10,000 n / min for 20 minutes at a high speed. After centrifugation, the supernatant is filtered with a filter membrane with a pore size of 0.22 μm to obtain a solution.

[0064] 4) Dialyze the solution obtained in the above steps with a dialysis bag with a molecular weight cut-off of 1000, put the dialyzed solution...

Embodiment 2

[0081] (1)MoS 2 Preparation of quantum dot powder

[0082] 1) Dissolve 0.338g and 0.13g of cystamine dihydrochloride and ammonium tetrathiomolybdate in 36mL deionized water respectively. Adjust the pH value of the mixed solution to 8 with ammonia water or hydrochloric acid.

[0083] 2) After the above mixed solution was sonicated for 20 minutes, it was transferred into a 50 mL stainless steel reaction kettle with a polytetrafluoroethylene liner, heated at 210° C., and reacted for 14 hours.

[0084] 3) After the reaction is finished, the reactor is left to stand for 10 minutes. Take the supernatant suspension and use a high-speed centrifuge to centrifuge at a speed of 10,000 n / min for 20 minutes at a high speed. After centrifugation, the supernatant is filtered with a filter membrane with a pore size of 0.22 μm to obtain a solution.

[0085] 4) Dialyze the solution obtained in the above steps with a dialysis bag with a molecular weight cut-off of 1000, put the dialyzed solut...

Embodiment 3

[0093] (1)MoS 2 Preparation of quantum dot powder

[0094] 1) Dissolve 0.45 g and 0.13 g of cystamine dihydrochloride and ammonium tetrathiomolybdate in 36 mL of deionized water, and adjust the pH value of the mixed solution to 9 with ammonia water or hydrochloric acid.

[0095] 2) After the above mixed solution was sonicated for 15 minutes, it was transferred into a 50 mL stainless steel reaction kettle with a polytetrafluoroethylene liner, heated at 220° C., and reacted for 12 hours.

[0096] 3) After the reaction is completed, the reactor is left to stand for 15 minutes. Take the supernatant suspension and use a high-speed centrifuge to centrifuge at a speed of 10,000 n / min for 20 minutes at a high speed. After centrifugation, the supernatant is filtered with a filter membrane with a pore size of 0.22 μm to obtain a solution.

[0097] 4) Dialyze the solution obtained in the above steps with a dialysis bag with a molecular weight cut-off of 1000, put the dialyzed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com