Conductive ink of ultra-low haze silver nanowire film and its preparation method and application

A silver nanowire and conductive ink technology, which is applied in the field of conductive ink and its preparation of ultra-low haze silver nanowire film, can solve the problems of high vacuum equipment, reduce costs, etc., achieve high production efficiency and ensure ultra-low haze , anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A preparation method of a conductive ink of an ultra-low haze silver nanowire film, comprising the following steps:

[0066] The synthesis of step A, silver nanowires,

[0067] Step A1. Weigh 0.84g of PVP (molecular mass: 500,000) into a 250ml Erlenmeyer flask, put 15ml of ethylene glycol solution into it, and place it on a heating plate at 130°C for 2 hours until PVP is completely dissolved and cooled naturally to obtain PVP Ethylene glycol solution;

[0068] Step A2, weigh 0.6g AgNO 3 Add 15mL of ethylene glycol, in a water bath at 4°C, ultrasonic at 100Hz for 7min to AgNO 3 Completely dissolved to get AgNO 3 Ethylene glycol solution;

[0069] Step A3, weigh 0.02gNaCl and 0.02gNaBr and dissolve them in 1ml ethylene glycol respectively to obtain two kinds of halogen ion ethylene glycol solutions;

[0070] Step A4, weigh 100mL of ethylene glycol and place it in a flask, and immerse the flask in an oil bath at room temperature, successively add the halide ion ethyle...

Embodiment 2

[0085] A preparation method of a conductive ink of an ultra-low haze silver nanowire film, comprising the following steps:

[0086] The synthesis of step A, silver nanowires,

[0087] Step A1. Weigh 0.4g of PVP (molecular mass: 360,000) into 15ml of ethylene glycol solution, place on a heating plate at 130°C for 2 hours until PVP is completely thermally dissolved, then cool naturally to obtain a PVP ethylene glycol solution;

[0088] Step A2, weigh 0.5g AgNO 3 Add 15mL of ethylene glycol, in a water bath at 6°C, ultrasonic at 100Hz for 8min to AgNO 3 Completely dissolved to get AgNO 3 Ethylene glycol solution;

[0089] Step A3, taking 0.1g NaCl and dissolving it in 4ml ethylene glycol to obtain NaCl ethylene glycol solution;

[0090] Step A4, weigh 100mL of ethylene glycol and place it in a flask, and immerse the flask in an oil bath at room temperature, successively add the NaCl ethylene glycol solution obtained in step A3, the AgNO solution obtained in step A2 3 The PVP...

Embodiment 3

[0105] A preparation method of a conductive ink of an ultra-low haze silver nanowire film, comprising the following steps:

[0106] The synthesis of step A, silver nanowires,

[0107] Step A1. Weigh 20g of PVP (molecular mass: 1.3 million) and put it into 170ml of ethylene glycol solution, place it on a heating plate at 130°C for 2 hours until the PVP is completely thermally dissolved, then cool naturally to obtain a PVP ethylene glycol solution;

[0108] Step A2, weigh 10g AgNO 3 Add 150mL ethylene glycol, in 8℃ water bath, 100Hz ultrasonic 9min to AgNO 3 Completely dissolved to get AgNO 3 Ethylene glycol solution;

[0109] Step A3, weigh 0.8g FeCl 3 Dissolve in 40ml of ethylene glycol to get FeCl 3 Ethylene glycol solution;

[0110] Step A4, weigh 1140mL ethylene glycol and place it in a flask, and immerse the flask in an oil bath at room temperature, and successively add the FeCl obtained in step A3 3 AgNO obtained in ethylene glycol solution, step A2 3 The PVP ethy...

PUM

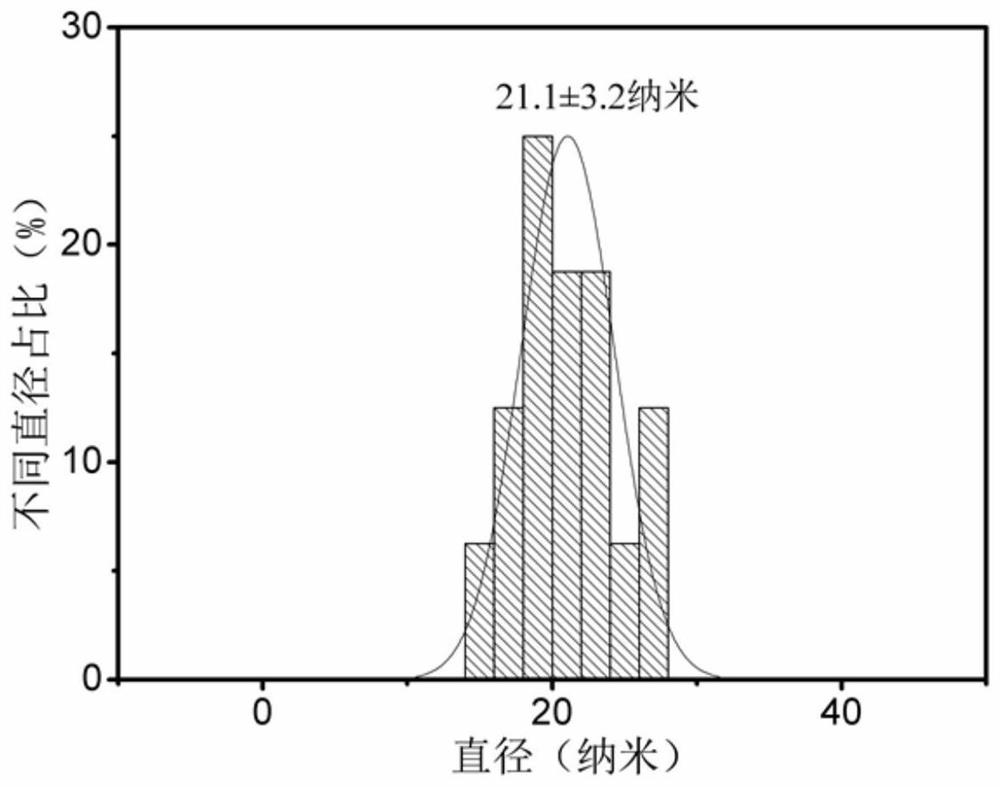

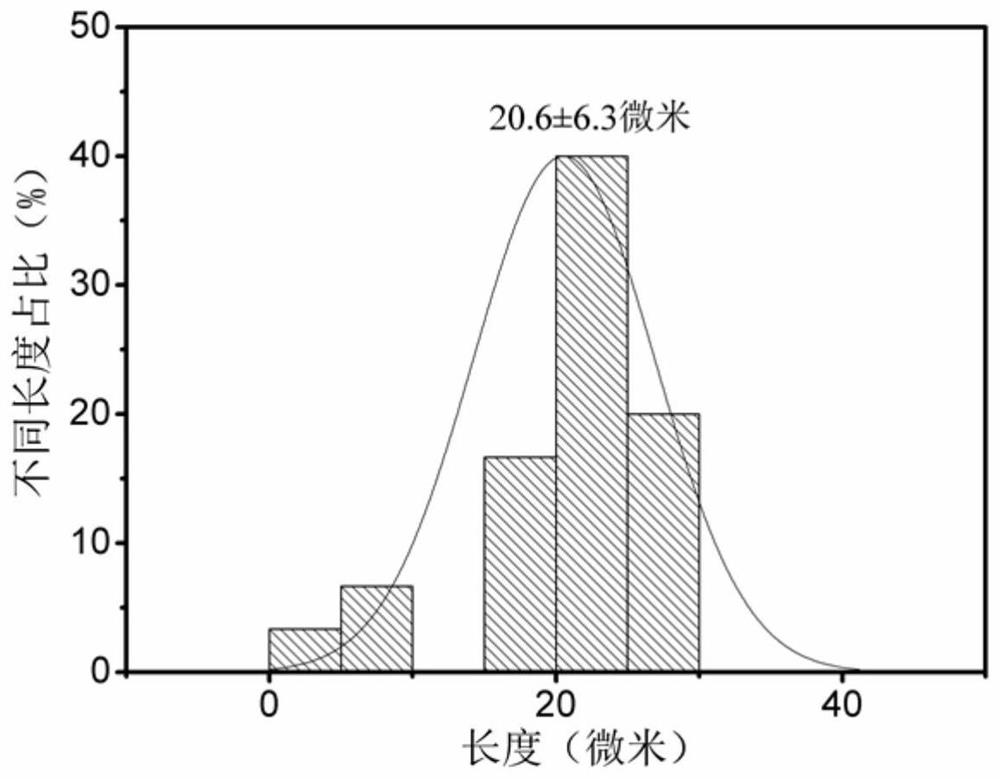

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com