Submicron active mixed material and preparation method thereof

A kind of active mixed material and sub-micron technology, applied in the field of building materials, can solve the problems of uneven mixing of fine powder, easy moisture absorption and accumulation, easy to produce shrinkage, etc., achieve low price, excellent crack resistance, and improve utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of submicron active mixed material in the embodiment comprises the following steps:

[0029] 1) take each raw material by weight percentage;

[0030] 2) Add each raw material to a high-efficiency ball mill, add grinding aids for ultrafine grinding to a specified particle size;

[0031] 3) Mix the ground powder evenly and pack it into the warehouse.

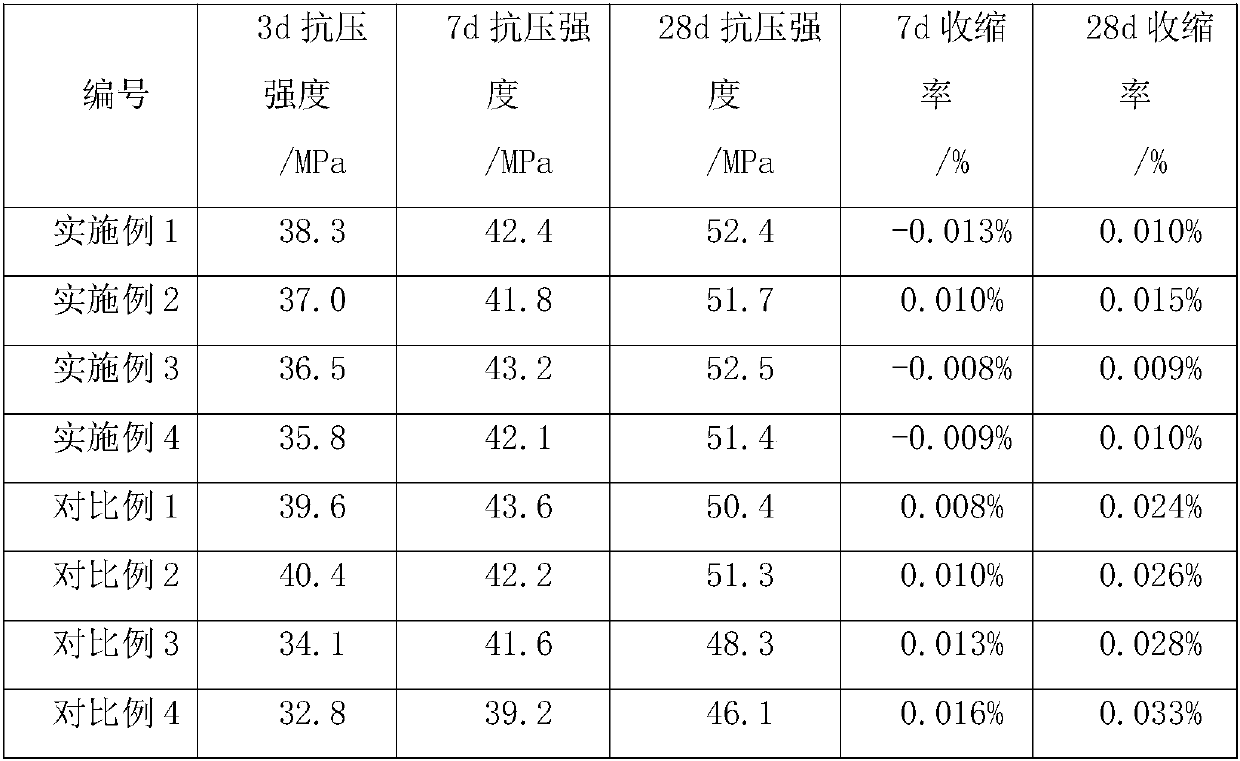

[0032] The embodiment and the comparative example were carried out the mortar experiment to measure the mechanical properties, and the shrinkage rate of the specimen was measured, and the cement used in the test was P.O42.5 grade ordinary Portland cement. For ease of recording, the particle size of A μm in the examples indicates that the maximum particle size of the raw material is A μm, for example, 0.4 μm marble stone powder indicates that the maximum particle size of marble stone powder is 0.4 μm.

Embodiment 1

[0034] The composition of the submicron active mixture is: 0.4μm marble stone powder 50%, 0.6μm basalt stone powder 13.5%, 0.5μm bauxite 15%, 0.4μm dihydrate gypsum 20%, NaOH 1.5%. Glue experiment.

Embodiment 2

[0036] The composition of the submicron active mixed material is: 60% of 0.2μm limestone powder, 10% of 0.4μm quartz stone powder, 10% of 0.5μm bauxite, 19% of 0.6μm anhydrite, Na 2 SiO 3 1%, the mixed material replaces 20% cement for mortar experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com