Economic and environment-friendly gel foam for preventing and curing coal spontaneous combustion

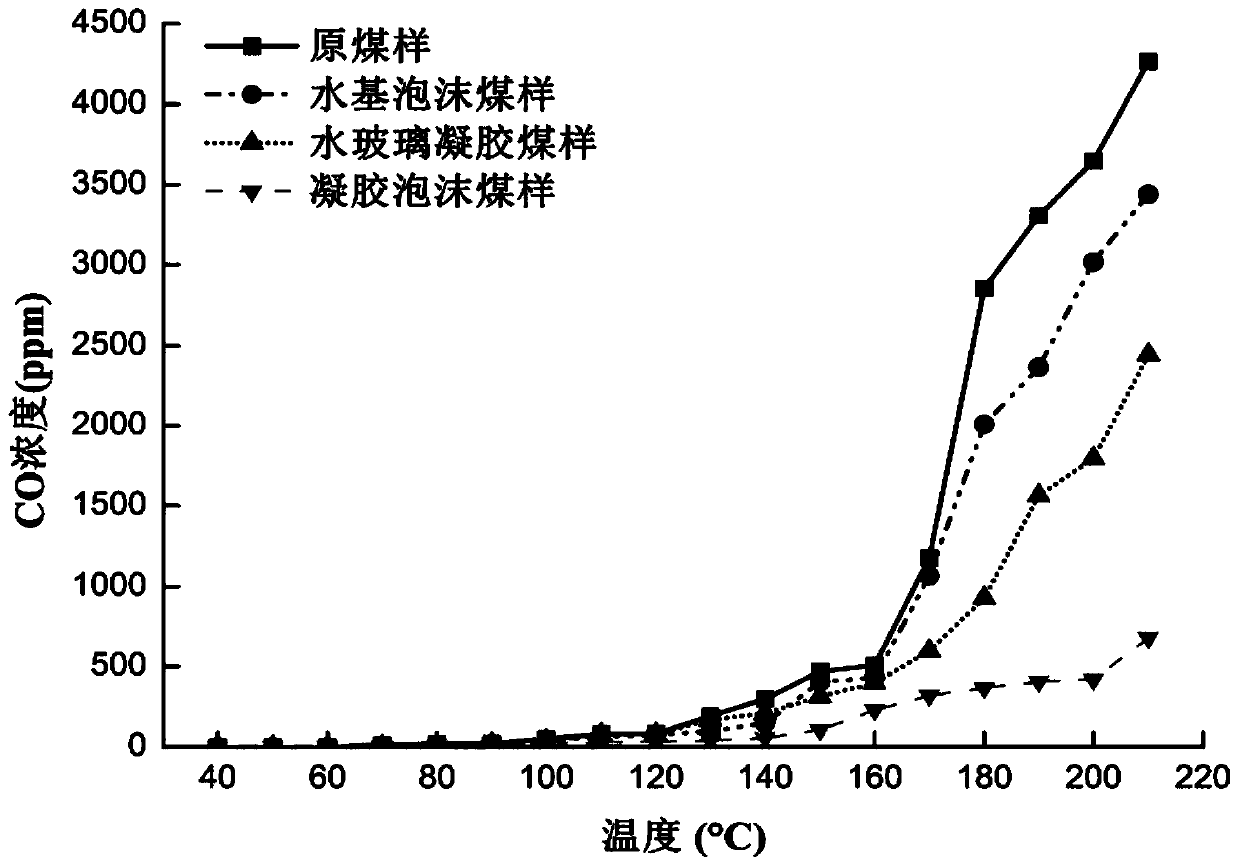

A technology of gel foam and coal spontaneous combustion, which is applied in dust prevention, fire prevention equipment, fire prevention, etc. It can solve the problems of limited application and high cost of polymer gel foam, and achieve increased foam volume, low cost, and gelation time controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to the quality of the economical and environment-friendly gel foam base liquid is 100g, the mass concentration of the prepared compound blowing agent (sodium fatty alcohol polyoxyethylene ether sulfate: sodium lauryl sulfate = 1:1) is 0.8%, and the modified silicon The mass concentration of resin polyether emulsion is 0.25%, the mass concentration of water glass is 15%, the mass concentration of NaHCO3 is 1%, and the rest is water.

[0040] First, mix water glass with deionized water, stir well to obtain a mixed solution; mix fatty alcohol polyoxyethylene ether sodium sulfate, sodium lauryl sulfate, modified silicone resin polyether emulsion and NaHCO 3Add it to the mixture in turn, stir mechanically at a speed greater than 1000r / min for more than 1min, and use the Waring-Blender stirring method to foam to form gel foam.

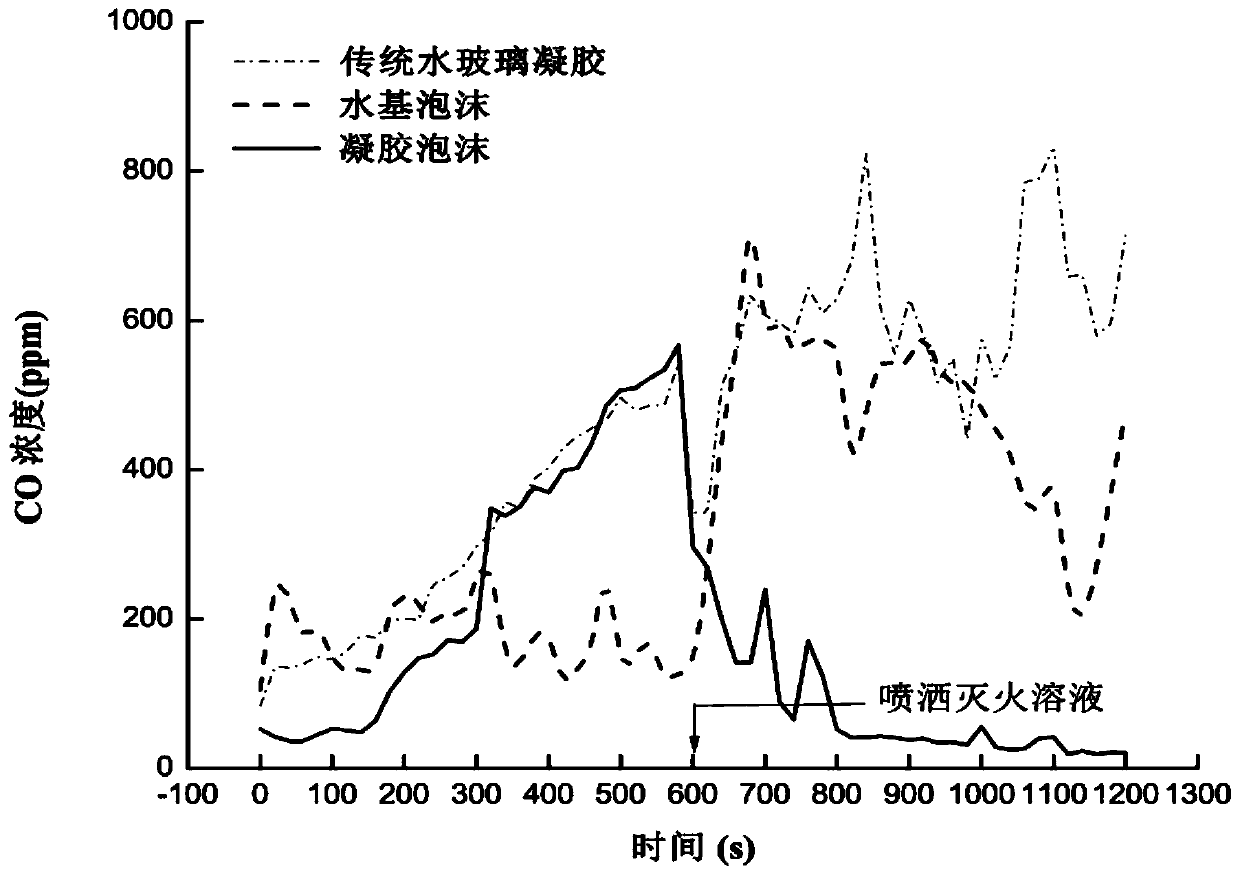

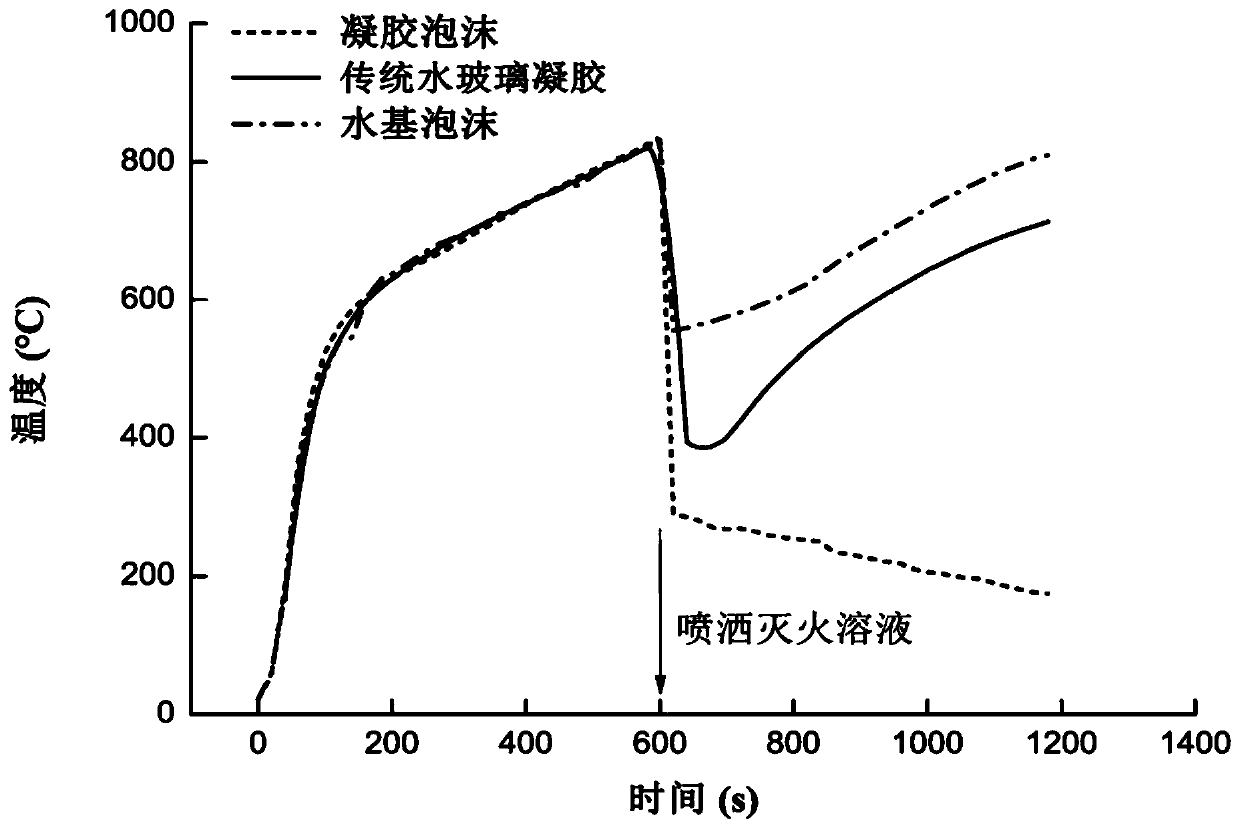

[0041] After the briquettes are burned in a self-made combustion furnace for 10 minutes, the same amount (300-600ml) of gel foam, water gla...

Embodiment 2

[0047] According to the quality of the economical and environment-friendly gel foam base liquid is 100g, the mass concentration of the prepared compound blowing agent (sodium fatty alcohol polyoxyethylene ether sulfate: sodium lauryl sulfate = 1:1) is 0.8%, and the modified silicon The mass concentration of resin polyether emulsion is 0.25%, the mass concentration of water glass is 12%, NaHCO 3 The mass concentration is 2%, and the rest is water.

[0048] First, mix water glass with deionized water, stir well to obtain a mixed solution; mix fatty alcohol polyoxyethylene ether sodium sulfate, sodium lauryl sulfate, modified silicone resin polyether emulsion and NaHCO 3 Add it to the mixture in turn, stir mechanically at a speed greater than 1000r / min for more than 1min, and use the Waring-Blender stirring method to foam to form gel foam.

[0049] Using the same method as in Example 1, the temperature of the briquettes dropped by 65.52% after the gel foam was sprayed, and the t...

Embodiment 3

[0051] According to the quality of the economical and environment-friendly gel foam base liquid is 100g, the mass concentration of the prepared compound blowing agent (sodium fatty alcohol polyoxyethylene ether sulfate: sodium lauryl sulfate = 1:1) is 0.8%, and the modified silicon The mass concentration of resin polyether emulsion is 0.25%, the mass concentration of water glass is 10%, NaHCO 3 The mass concentration is 5%, and the rest is water.

[0052] First, mix water glass with deionized water, stir well to obtain a mixed solution; mix fatty alcohol polyoxyethylene ether sodium sulfate, sodium lauryl sulfate, modified silicone resin polyether emulsion and NaHCO 3 Add it to the mixture in turn, stir mechanically at a speed greater than 1000r / min for more than 1min, and use the Waring-Blender stirring method to foam to form gel foam.

[0053] Using the same method as in Example 1, the temperature of the briquettes dropped by 61.36% after the gel foam was sprayed, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com