Preparation method and application of lauramide concrete foaming agent

A laurylamide-type concrete technology, which is applied in the manufacture of foamed concrete and the preparation of laurylamide-type concrete foaming agent, can solve problems such as limited sources, unsatisfactory foam stability and foaming multiple, and bubble bursting, and achieve reduction Effects of solution surface tension, small critical micelle concentration, and increase in foam volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

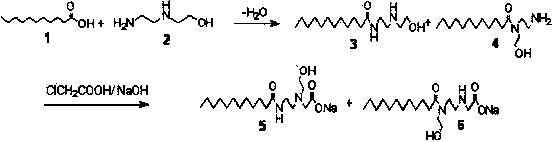

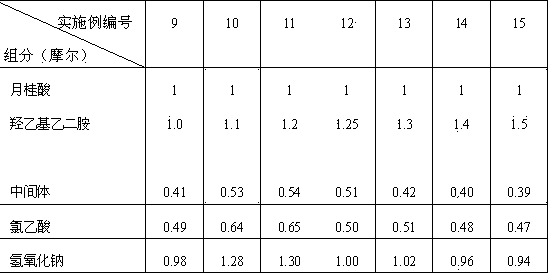

[0022] A preparation method of laurylamide type concrete foaming agent, comprises the following steps:

[0023] Add 10 grams of lauric acid and 15 milliliters of toluene into a three-neck flask with a condensing device, heat until the lauric acid is completely dissolved, then add 6.2 grams of hydroxyethylethylenediamine, rapidly raise the temperature to 155°C and keep it warm for 3 hours. Cool to obtain a yellow solid, which is washed with anhydrous acetone and vacuum-dried to obtain white intermediates 3 and 4 (referring to the chemical reaction formula of the above-mentioned synthetic route), a total of 7.6 grams, with a yield of 53.1%;

[0024] Put 5.7 grams of the intermediate into a three-necked flask with a condensing device, stir and heat up to 80-95°C, and after the intermediate is completely melted, slowly add an aqueous solution of sodium chloroacetate with a mass concentration of 10-20%, and in the The reaction was kept at the temperature for 4 hours. After cooling...

Embodiment 2

[0027] The lauramide type concrete foaming agent prepared in Example 1 is used in low bulk density foam concrete; weigh 350 grams of 42.5R ordinary Portland cement, 150 grams of Class I fly ash, 139.2 grams of water, and 1.7 grams of polycarboxylic acid Water reducer, 1 gram of polypropylene fiber, 1.5 gram of coagulant, 1000 milliliters of foam, to prepare foamed concrete with low bulk density, 28 days of curing in a standard curing box, its compressive strength is 2.77MPa, and its bulk density is 477 kg / m 3 .

Embodiment 3

[0029] The lauramide type concrete foaming agent prepared in Example 1 is used in low bulk density foam concrete; weigh 350 grams of 42.5R ordinary Portland cement, 150 grams of Class I fly ash, 139.1 grams of water, and 1.9 grams of polycarboxylic acid Water reducing agent, 1 gram of polypropylene fiber, 4 grams of coagulant, 1000 milliliters of foam to prepare foam concrete with low bulk density, 28 days of curing in a standard curing box, its compressive strength is 2.31MPa, and its bulk density is 430 kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com