Method for preparing two-dimensional ordered mesoporous nanosheet by inorganic salt interface induced assembling

A technology of inorganic salts and nanosheets, which is applied in nanotechnology, nanocarbon, inorganic chemistry, etc. for materials and surface science, and can solve the difficulty of assembling and modifying single-layer nanosheets, two-dimensional single-layer nanosheets involving less and other problems, to achieve the effect of simple assembly method, highly ordered pores, and good ethanol dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

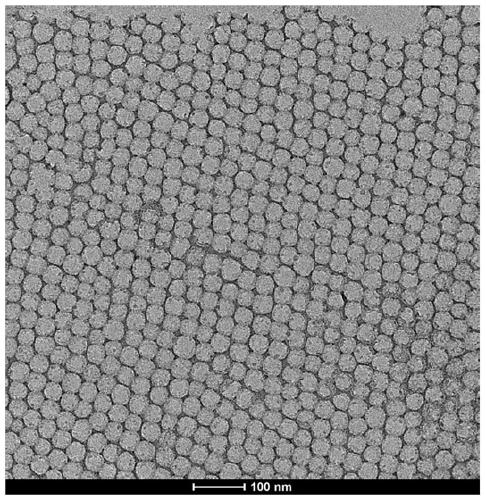

[0029] PEOs117 - b -PS 113 (Molecular weight 16700 g·mol -1 , 0.1 g) was dissolved and dispersed in 10.0 g THF solution, then 2.0 g phenolic resin precursor solution (20 wt%, containing 0.25 g phenol and 0.15 g formaldehyde) dissolved in THF was added, and magnetic stirring was continued at room temperature for 0.5 h to form a uniform transparent solution , pour a certain mixed solution into the inorganic salt NaCl solid crystal powder, perform suction filtration for 30-120 s (or centrifuge at 3000 rpm / 3 min) with a vacuum of 2 Calcined under protection for 3 h to decompose the template agent, the heating rate was 1 °C / min, after the product was cooled, it was washed with deionized water for 3-5 times to remove the NaCl template, and the obtained two-dimensional single-layer ordered mesoporous polymer nanosheets The pore size is 27 nm. If the calcination condition is adjusted to 600°C tube furnace with N 2 Calcined under protection for 3 h, with a heating rate of 1 °C / min,...

Embodiment 2

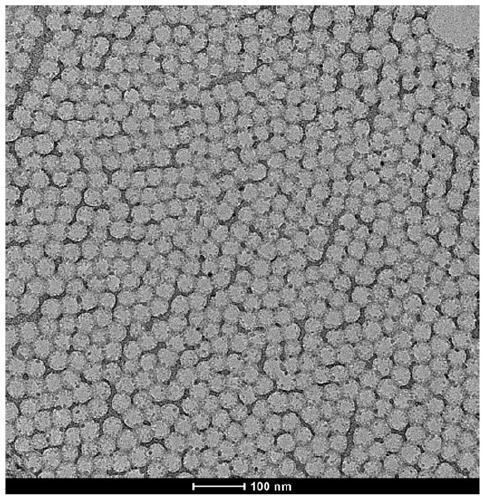

[0031] PEOs 117 - b -PS 113 (Molecular weight 16700 g·mol -1 or F127) and tetrabutyl titanate (TBOT, 0.2 g) were dissolved and dispersed in 10 mL THF solution, then concentrated hydrochloric acid (0.1 mL, 37%) and acetic acid (0.1 mL, 98%) were added, and magnetic stirring was continued at room temperature for 0.5 h, pour a certain mixed solution into the inorganic salt NaCl solid crystal powder, perform suction filtration for 30-120 s (or 3000 rpm / 3 min centrifugation) with a vacuum of 2 Calcined under protection for 2 h to decompose the template agent at a heating rate of 1 °C / min; then take out the solid in a muffle furnace and calcinate at 430 °C for 2 h in air at a heating rate of 1 °C / min, and use it after the product is cooled. Washed 3-5 times with deionized water to remove the NaCl template, the resulting two-dimensional monolayer ordered mesoporous TiO 2 The nanosheet pore size is 18nm.

Embodiment 3

[0033] PEOs 117 - b -PS 113 (Molecular weight 16700 g·mol -1 , 40 mg) and tetraethyl orthosilicate (TEOS, 0.2 g) were dissolved and dispersed in 4.0 g tetrahydrofuran solution, then 0.1 M hydrochloric acid (0.06 g) was added, and magnetic stirring was continued at room temperature for 0.5 h to form a uniform solution, and a certain amount of the mixed solution was poured into In the inorganic salt NaCl solid crystal powder, vacuum filter 2 Calcined under protection for 3 h to decompose the template agent at a heating rate of 1°C / min; then take out the solid in a muffle furnace and calcinate at 600°C for 2 h under air at a heating rate of 1°C / min, and use it after the product is cooled. Washed 3-5 times with deionized water to remove the NaCl template, the resulting two-dimensional single-layer ordered mesoporous SiO 2 The nanosheets have a pore size of 25 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com