Preparing method and application of A-site compound ion perovskite type ferroelectric fuel ceramic nano-powder material

A composite ion, perovskite technology, applied in the field of battery materials, can solve problems such as poor cycle performance, and achieve the effects of improving electrical conductivity, saving raw materials, and improving piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

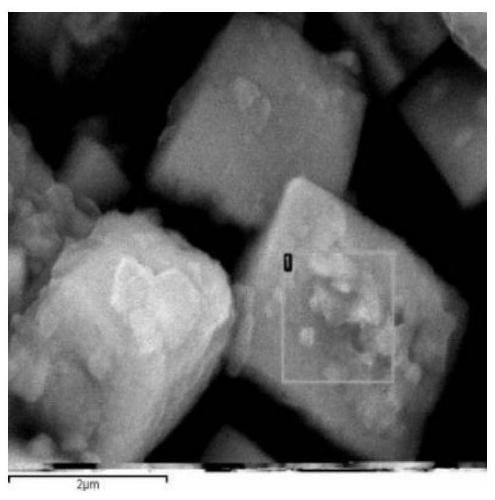

Image

Examples

preparation example Construction

[0034] The preparation method and application steps of a compound ion perovskite type ferroelectric fuel ceramic nano powder material of the present invention are as follows:

[0035] S1, dissolving the sodium hydroxide of flake or massive structure in deionized water, and wait for it to cool to obtain solution A, the molar ratio of sodium hydroxide and deionized water is (11~12):14;

[0036] S2. Add the titanium source, the bismuth source and the lithium source to the solution A obtained in step S1 in sequence, and make it fully stirred and evenly dissolved in the solution. The molar ratio of the titanium source, the bismuth source and the lithium source is 1:2:(2~1); The molar ratios of sodium hydroxide in step S1 to titanium source, bismuth source and lithium source in step S2 are (73-79): (10-11); (73-79): 8; (73-79): (2~1); The bismuth source is bismuth nitrate, the titanium source is tetrabutyl titanate, and the lithium source is lithium nitrate;

[0037] S3. Transfer t...

Embodiment 1

[0043] a. Weigh 73.1896g of NaOH and 7.7611g of Bi(NO 3 ) 3 ·5H 2 O, 2.2064g of LiNO 3 And 10.8902g tetrabutyl tertanoate, be dissolved in 166.34ml deionized water, form mixed solution;

[0044] b. Stir the mixed solution under magnetic stirring for 1 hour, and stir the solution evenly;

[0045] c. Transfer the mixed solution to a clean reactor, seal the reactor and place it in an oven, and react at a temperature of 160°C for 12 hours;

[0046] d. After the reaction is over, take out the reaction kettle, pour it into a beaker after it cools down, let it stand, and pour out the supernatant, control the speed of the centrifuge at 500 rpm, and centrifuge the solution until it is neutral;

[0047] e. Then place the sample in an oven at 80° C. for 10 hours to dry to obtain an A-site composite ion perovskite type ferroelectric sodium ion oxide combustion ceramic battery material.

Embodiment 2

[0049] a. Weigh 73.1896g of NaOH and 7.7611g of Bi(NO 3 ) 3 ·5H 2 O, 2.2064g of LiNO 3 Dissolve in 166.34ml deionized water with 10.8902g of tetrabutyl tertate to form a mixed solution;

[0050] b. Stir the mixed solution under magnetic stirring for 1 hour, and stir the solution evenly;

[0051] c. Transfer the mixture to a clean reactor, seal and tighten the reactor, place it in an oven, and react at a temperature of 160°C for 24 hours;

[0052] d. After the reaction is over, take out the reaction kettle, pour it into a beaker after it cools down, let it stand, and pour out the supernatant, control the speed of the centrifuge at 550 rpm, and centrifuge the solution until it is neutral;

[0053] e. Then place the sample in an oven at 80° C. for 10 hours to dry to obtain an A-site composite ion perovskite type ferroelectric sodium ion oxide combustion ceramic battery material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com