Continuous flow wetland type microbial fuel cell reactor sewage treatment device

A sewage treatment device and fuel cell technology, applied in the direction of biological water/sewage treatment, biochemical fuel cell, water/sewage multi-stage treatment, etc., can solve the problems of siltation, large footprint, blockage, etc., to avoid easy blockage, Avoid the effect of affecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

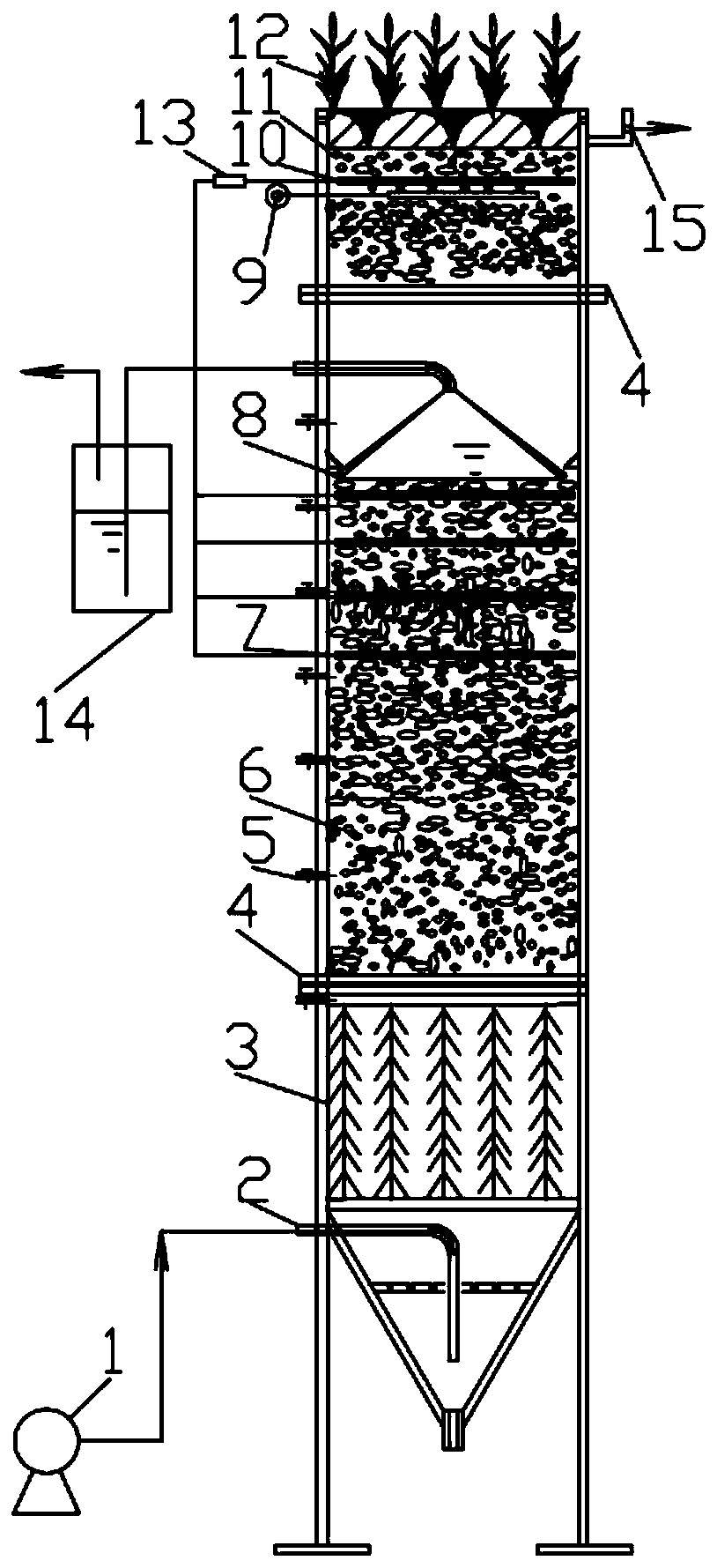

[0032] Such as figure 1 As shown, a continuous flow wetland type microbial fuel cell reactor sewage treatment device includes a hydrolytic acidification tank (3), an anode chamber (6) and a constructed wetland cathode chamber arranged in sequence from bottom to top.

[0033] The sewage to be treated is input into the hydrolysis acidification tank (3) through the water inlet system, the water inlet system includes the water inlet pump (1) and the water distributor (2); the water distributor (2) is composed of the water inlet pipe and the perforated plate, wherein The water pipe is connected to the water inlet pump (1), the perforated plate is arranged at the bottom of the hydrolytic acidification tank (3), and holes with a diameter of 10mm are evenly distributed on the perforated plate, and the hydrolytic acidification tank (3) contains elastic fillers. Sewage enters the bottom of the perforated plate through the water inlet pump (1) and the water inlet pipe. After the upward f...

Embodiment 2

[0042] A continuous flow wetland type microbial fuel cell reactor sewage treatment device, the diameter of the uniformly distributed holes on the perforated plate of the water distributor 2 used is 12mm,

[0043] Its structure is the same as that of Example 1, the particle diameter of the granular activated carbon filled in the anode chamber is 4-6mm, the particle diameter of the anaerobic granular sludge is 4-6mm, the volume ratio of the two is 1:1, and the filler supporting layer 4 has a pore size smaller than 2mm perforated HDPE sheet. The water seal tank 14 controls the pressure in the air chamber of the three-phase separator 8, and the water seal water pressure is 35cm.

[0044] The particle size of the activated carbon filled in the cathode chamber of the constructed wetland is 6-8mm, and 12 plants selected in the cathode chamber of the constructed wetland are calamus, and the planting density is 15 plants / m 2 .

[0045] The resistance value of the resistor 13 is 1000Ω...

Embodiment 3

[0051] A continuous flow wetland type microbial fuel cell reactor sewage treatment device, the diameter of the uniformly distributed holes on the perforated plate of the water distributor 2 used is 15mm. The particle size of the granular activated carbon filled in the anode chamber is 3-6mm, the particle size of the anaerobic granular sludge is 3-6mm, the volume ratio of the two is 2:1, and the water seal tank 14 controls the water seal in the air chamber of the three-phase separator 8 The water pressure is 45cm, the particle size of the activated carbon filled in the cathode chamber of the constructed wetland is 5-7mm, the plants 12 selected in the cathode chamber of the constructed wetland are cattails, and the planting density is 20 plants / m 2 . The resistance value of the resistor 13 is 2000Ω.

[0052] All the other structures are with embodiment 1.

[0053] Using the above-mentioned continuous flow wetland type microbial fuel cell reactor sewage treatment device to trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com