Graphene-modified polyamide 66/polyamide 6 fiber and preparation method and application thereof

A graphene modification, graphene technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problem of uneven dispersion, achieve the effect of expanding performance and application fields, improving performance and application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesis of PA6 / graphene samples:

[0037] Weigh 10.35g of graphene oxide, add it to 230g of molten caprolactam liquid, ultrasonically disperse it for 2h, then transfer it to a 500ml three-neck flask, add 0.3g of adipic acid and 9g of water at the same time, set the temperature of the oil bath so that the inside of the flask The temperature was raised to 230°C and kept for 3 hours, then the temperature was raised to 240°C to terminate the reaction. The sample was poured out, and after cooling, it was pulverized by a pulverizer for use.

Embodiment 2

[0039] Nylon 66 / nylon 6 / graphene slice sample preparation:

[0040] Get 134g of the sample in Example 1 and join in 1366g of nylon 66 saline solution, wherein the concentration of the saline solution is 50wt%, add molecular weight regulator hexamethylenediamine 9.5g simultaneously, stabilizer SEED 15g, matting agent titanium dioxide 3g, water bath Stir in the middle for 1h, transfer to a 5L polymerization reactor, heat the temperature in the kettle to 205°C, keep the pressure at 1.3MPa, react for 1.5h, then gradually raise the temperature to 290°C, and at the same time gradually reduce the pressure in the kettle to normal pressure, react for 2h, and prepare Obtain graphene-modified nylon 66 / nylon 6 composite slices.

Embodiment 3

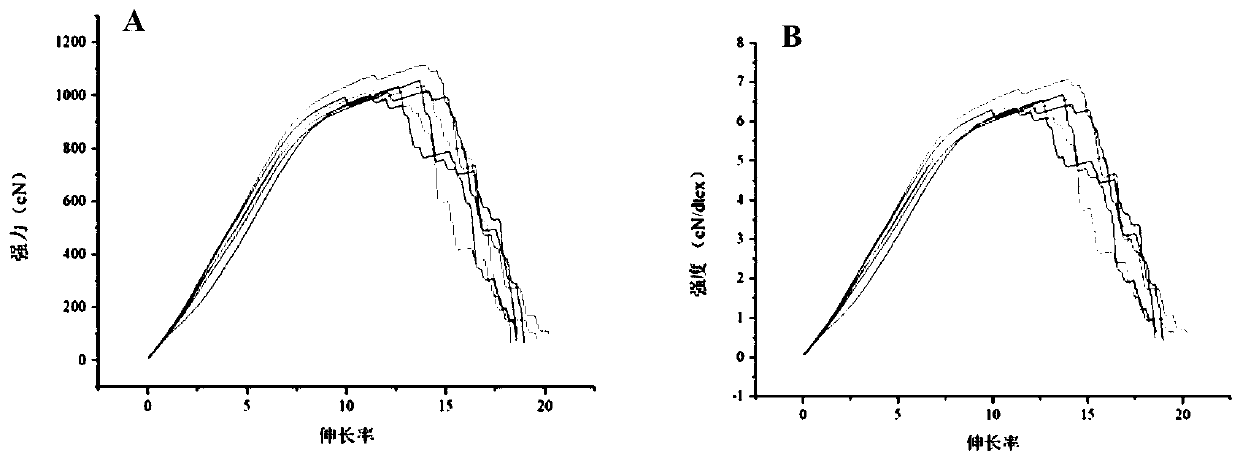

[0042] Graphene modified nylon 66 / nylon 6 fiber:

[0043] The prepared nylon 66 / nylon 6 / graphene slices were dried in a vacuum drying oven at 100°C for 8 hours, extruded through a screw, the temperature of the first zone was 290°C, the temperature of the second zone, the third zone and the fourth zone was 320°C, and the melt transfer elbow The temperature is 320°C, the speed of the metering pump is 30R / min, and the temperature is 320°C. After passing through the spinneret (that is, the component, the temperature is 320°C), the primary fiber is formed, which is the fine fluid of the sample nylon 66 / nylon 6 / graphene. The air is condensed and solidified into fiber filaments. Among the guide rollers, the speed of the first roller is 1000m / min, the speed of the second roller is 1020m / min, and the winding speed is 1020m / min. The denier of the prepared single filament is 687dtex to obtain graphene-modified nylon 66 / nylon 6 The as-spun fiber was stretched 4.3 times, and the post-drawi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com