High-yield high-elongation-rate die-casting alloy material for mobile phone medium plate and preparation method

A high-elongation, die-casting alloy technology, applied in the field of aluminum alloys, can solve the problems of reducing alloy fracture toughness, matrix interface peeling, interstitial dislocations, etc., and achieve improved yield strength, high yield elongation, and reduced lattice distortion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

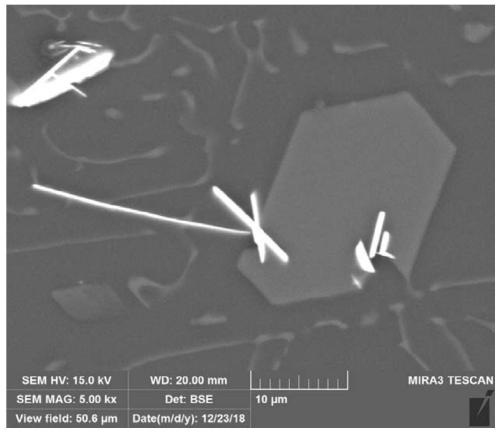

Image

Examples

Embodiment 1-10

[0033] A high-yield and high-elongation thin-walled die-casting aluminum alloy, comprising the following components in mass percentage in Table 1, and the balance being aluminum and unavoidable impurities.

[0034] Si: 1.8wt%-4.0wt%; Mg: 4.0wt%-7.0wt%; Mn: 0.1wt%-1.2wt%; Ce<1.0wt%; Cu<0.5wt%; Cr<0.5wt%; Fe: 0.1wt%-1.0wt%; Ti: 0.01wt%-0.25wt%, the remaining impurities are controlled below 0.1wt%, and the balance is Al.

[0035] Table 1 is the content table of each element in the aluminum alloy of Examples 1-10 and the performance table of the middle plate of the mobile phone prepared therefrom

[0036]

[0037] The preparation method of aluminum alloy described in above-mentioned each embodiment is:

[0038] 1) Calculate the quality of the required master alloy according to the ratio, and prepare materials;

[0039] 2) Put the high-purity aluminum element into the heating furnace, heat it to 600°C, completely melt and keep it for 15 minutes;

[0040] 3) be heated up to 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com