Method and system for treating high-concentration phosphating wastewater

A treatment method and high-concentration technology are applied in the field of treatment methods and systems for high-concentration phosphating wastewater, which can solve the problems of not meeting actual use requirements, slow floc settling speed, and large floor space, and improve the dosing amount. Large, short residence time, the effect of accelerated precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

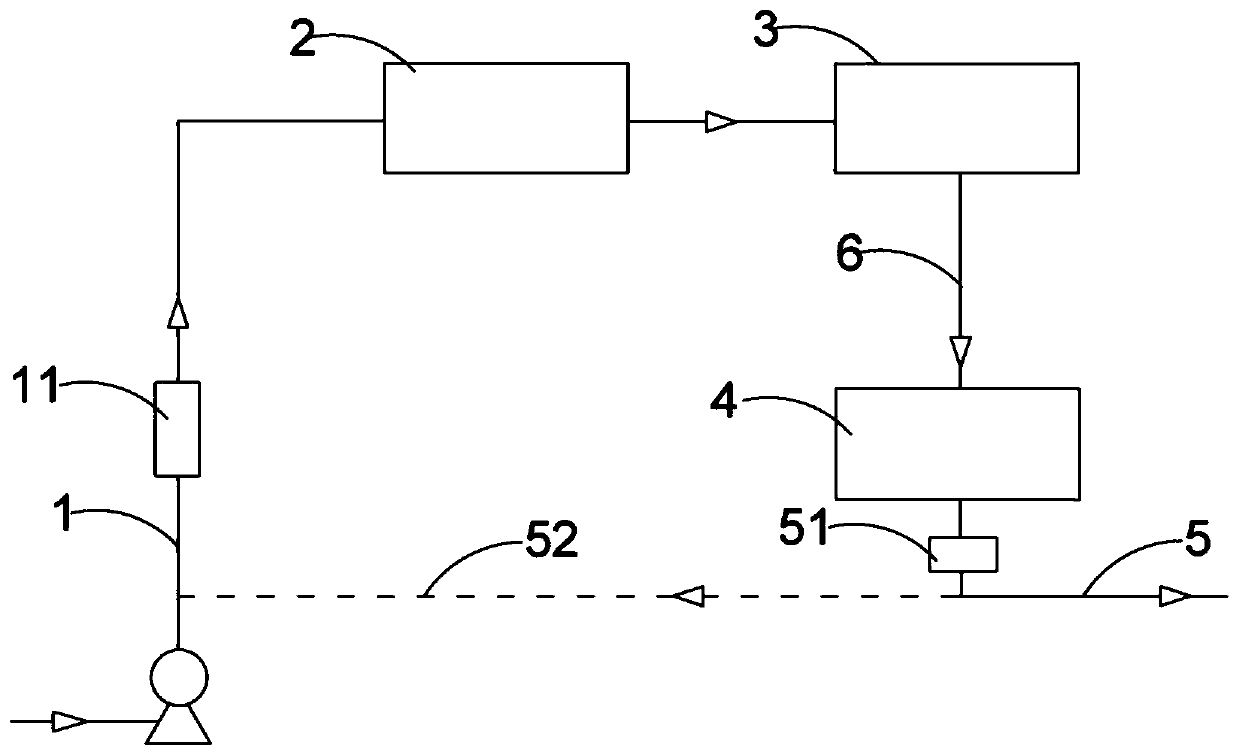

[0036] see figure 1 , a treatment system for high-concentration phosphating wastewater; including a water inlet pipe 1, a primary mixing pool 2, a secondary mixing pool 3, an air flotation pool 4 and an outlet pipe 5, the primary mixing pool 2, the secondary mixing pool 3 and the air flotation tank 4 are connected through the delivery pipeline 6 in turn, and the waste water is connected to the first-level mixing tank 2 from the water inlet pipe 1, and in the first-level mixing tank 2, it is forced to stir with the coagulant PAC and magnetic powder to form a first-level mixing tank system. The primary mixing system flows into the secondary mixing tank 3 through the delivery pipeline 6, and is forced to stir with the coagulant PAM in the secondary mixing tank 3 to form a secondary mixing system. The secondary mixing system flows into the air flotation tank 4 through the delivery pipeline 6, and the secondary mixing The system air flotation tank is separated into scum and effluen...

Embodiment 2

[0041] A treatment method for high-concentration phosphating wastewater,

[0042]The average COD of the sewage to be treated is 251.637 mg / L, the average total phosphorus concentration is 267.851 mg / L, and the average total nickel content is 14.332 mg / L. The sewage is treated according to the following steps:

[0043] (1) Adjust pH: The pH value of phosphating wastewater is stabilized in the neutral range of 6~7 through online real-time regulation;

[0044] (2) Level 1 mixing: the phosphating wastewater is pumped into the flocculation reaction tank through the lift pump, and 50mg / L PAC coagulant and 10mg / L magnetic powder are added, and stirred and mixed for 25 minutes to form a first-level mixing system;

[0045] (3) Two-level mixing: the first-level mixing system enters the coagulation aid reaction tank, and 20mg / L PAM coagulant aid is added, and the mixing reaction is stirred for 25 minutes to form a second-level mixing system;

[0046] (4) Air flotation separation: The se...

Embodiment 3

[0050] A treatment method for high-concentration phosphating wastewater,

[0051] The average COD of the sewage to be treated is 370.311 mg / L, the average total phosphorus concentration is 273.862 mg / L, and the average total nickel content is 16.663mg / L. The sewage is treated according to the following steps:

[0052] (1) Adjust pH: The pH value of phosphating wastewater is stabilized in the neutral range of 6~7 through online real-time regulation;

[0053] (2) Level 1 mixing: Phosphating wastewater is pumped into the flocculation reaction tank through a lift pump, 75mg / L PAC coagulant and 15mg / L magnetic powder are added, and the mixing reaction is stirred for 30 minutes to form a first-level mixing system;

[0054] (3) Two-stage mixing: and the mixed system enters the coagulation aid reaction tank, and 30mg / L PAM coagulant aid is added, and the mixing reaction is stirred for 30 minutes to form a two-stage mixing system;

[0055] (4) Air flotation separation: the secondary m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com